Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Pt-Au Crucible For FHC-00

Pt-Au Mold For FHC-00

FHC-PT

-

Click to select

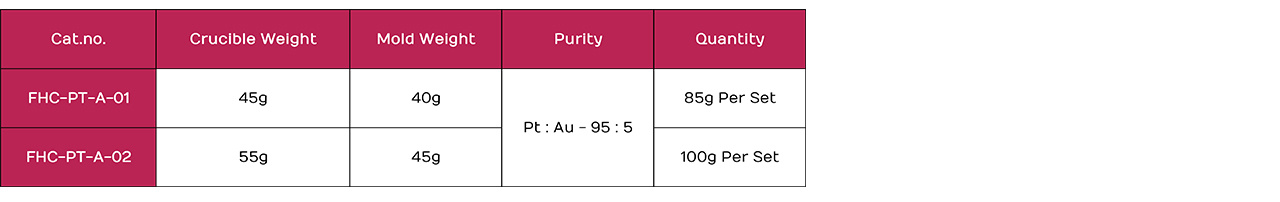

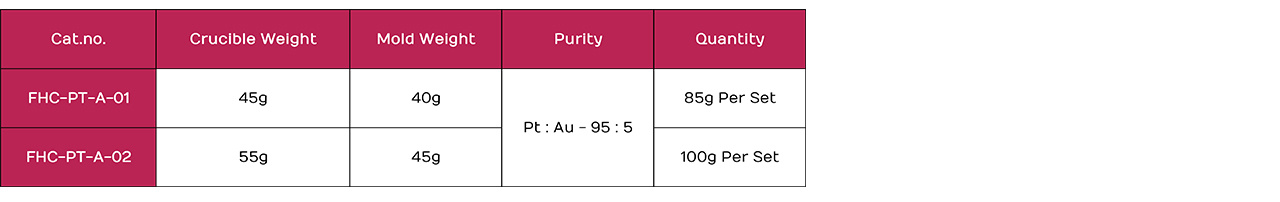

- FHC-PT-A-01,85g

- FHC-PT-A-02,100g

Inventory

4

隐藏域元素占位

Overview

The Pt-Au Crucible for FHC-00 is an apparatus employed in high-temperature fusion experiments, usually fabricated by blending platinum and gold in a specific proportion (e.g., 95:5). It possesses a high melting point (the melting point of platinum is approximately 1772℃), can be utilized stably at temperatures exceeding 1000℃, and exhibits extremely stable chemical properties. It is resistant to strong acid and alkali corrosion and is not prone to react with samples, making it suitable for experiments such as X-ray fluorescence spectrometry (XRF). It has excellent thermal conductivity and is capable of rapidly and uniformly transferring heat to the sample.

Features

1. High Melting Point: The melting point of platinum is as high as 1772°C, and that of gold is 1064°C. The combination of the two enables the crucible to be stably employed in high-temperature environments above 1000°C without melting or deforming, fulfilling the high-temperature melting requirements of high-frequency melting machines and other devices.

2. Excellent Thermal Conductivity: It can rapidly and uniformly transfer heat to the sample, enhancing the melting efficiency and ensuring homogeneous heating of the sample.

3. Strong Corrosion Resistance: Platinum and gold possess stable chemical properties, being resistant to strong acids, strong alkalis, and molten metals. They are less prone to undergo chemical reactions with samples and reagents, avoiding sample contamination and guaranteeing accurate analysis results.

4. Comparatively Good Toughness: The addition of gold ameliorates the brittleness of platinum, endowing the crucible with a certain degree of toughness, making it less susceptible to cracking and prolonging its service life.

5. Smooth Surface: The surface is sleek and even, facilitating the outflow of the molten sample and the cleaning of the crucible, minimizing the interference of residues on subsequent experiments.

6. High Durability: Under normal usage and proper maintenance, platinum-gold crucibles can withstand multiple high-temperature melting operations without being prone to damage easily, have an extended service life, and offer high cost-effectiveness.

Technical data

1.The melting point of platinum is 1772 ℃. In fact, the maximum heating temperature of platinum crucible in use cannot exceed 1200 ℃. Considering the temperature error, it is recommended to use it below 1150 ℃.

2.Do not use too much force when taking the crucible, Too much force will cause the crucible to deform or bump.

3. Special platinum crucible clamp shall be used to take the heated crucible and casting dish (at least the head contacting the crucible clamp be wrapped with platinum).

4.It is recommended not to use manual operation too frequently (i.e. clamp the crucible with crucible tongs for melting, swaying and dumping). frequently manual operation is likely to cause deformation of the crucible and shorten the service life.

5. The heating and burning shall be carried out in the electric furnace or on the oxidation flame of the gas lamp, and the platinum crucible shall not be heated in the reduction flame or the flame emitting black smoke. Or make platinum utensils contact the blue flame core in the flame to prevent the formation of platinum carbide.

6. The crucible shall not contact any other metal (iron plate, electric furnace, etc.) when heating at high temperature, and shall not touch the thermocouple when putting it into the electric furnace.

7. Do not heat molten alkali metal compounds in platinum crucibles.Such as alkali metal oxide, alkali metal hydroxide, alkali metal nitrate, alkali metal nitrite, alkali metal chloride, alkali metal cyanide, etc.

8. The compounds containing heavy metals cannot be burned and heated in the platinum crucible. These heavy metals are easy to be reduced to metal and platinum to form alloys. (These heavy metals include: lead, bismuth, tin, antimony, arsenic, silver, mercury, copper, etc.)

9. The platinum crucible shall not be used to treat halogen and substances that can decompose halogen. Such as aqua regia, bromine water, mixtures of hydrochloric acid and oxidants such as chlorate, nitrate, permanganate, manganese dioxide, chromate, nitrite, and mixtures of halides and oxidants.

10 Ferric chloride has a significant corrosion effect on platinum. After a long time of use, there will be a thin layer of crystals on the surface of platinum utensils, which must be removed in time to prevent them from penetrating into platinum.

11 In the presence of reducing substances (such as filter paper, organic matter in the sample and other substances), it is not allowed to heat or burn substances containing a large amount of phosphorus and sulfur in the platinum crucible to avoid forming brittle platinum phosphide or platinum sulfide with platinum.

12 The sample containing a large amount of iron cannot be directly melted in a platinum crucible. A large amount of iron must be melted with hydrochloric acid first. The residue must be filtered before melting in the crucible. The polymetallic ore sample should be treated with hydrochloric acid and nitric acid first. The residue is incinerated in a porcelain crucible and then transferred to a platinum crucible for melting.

13 Most metals will form alloys with platinum at high temperatures, so metal samples cannot be directly melted in platinum crucibles, and appropriate pre oxidation treatment is required.

14 It is prohibited to heat and burn substances with unknown composition in platinum crucible.

keyword:

Previous:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Pt-Au Crucible For FHC-00

- Subtitle: Pt-Au Mold For FHC-00

- Model: FHC-PT

- 全部型号: FHC-PT-A-01,FHC-PT-A-02,Pt-Au Mold For FHC-00,Pt-Au Crucible

The Pt-Au Crucible for FHC-00 is an apparatus employed in high-temperature fusion experiments, usually fabricated by blending platinum and gold in a specific proportion (e.g., 95:5).

The Pt-Au Crucible for FHC-00 is an apparatus employed in high-temperature fusion experiments, usually fabricated by blending platinum and gold in a specific proportion (e.g., 95:5). It possesses a high melting point (the melting point of platinum is approximately 1772℃), can be utilized stably at temperatures exceeding 1000℃, and exhibits extremely stable chemical properties. It is resistant to strong acid and alkali corrosion and is not prone to react with samples, making it suitable for experiments such as X-ray fluorescence spectrometry (XRF). It has excellent thermal conductivity and is capable of rapidly and uniformly transferring heat to the sample.

-

1. High Melting Point: The melting point of platinum is as high as 1772°C, and that of gold is 1064°C. The combination of the two enables the crucible to be stably employed in high-temperature environments above 1000°C without melting or deforming, fulfilling the high-temperature melting requirements of high-frequency melting machines and other devices.

2. Excellent Thermal Conductivity: It can rapidly and uniformly transfer heat to the sample, enhancing the melting efficiency and ensuring homogeneous heating of the sample.

3. Strong Corrosion Resistance: Platinum and gold possess stable chemical properties, being resistant to strong acids, strong alkalis, and molten metals. They are less prone to undergo chemical reactions with samples and reagents, avoiding sample contamination and guaranteeing accurate analysis results.

4. Comparatively Good Toughness: The addition of gold ameliorates the brittleness of platinum, endowing the crucible with a certain degree of toughness, making it less susceptible to cracking and prolonging its service life.

5. Smooth Surface: The surface is sleek and even, facilitating the outflow of the molten sample and the cleaning of the crucible, minimizing the interference of residues on subsequent experiments.

6. High Durability: Under normal usage and proper maintenance, platinum-gold crucibles can withstand multiple high-temperature melting operations without being prone to damage easily, have an extended service life, and offer high cost-effectiveness. -

1.The melting point of platinum is 1772 ℃. In fact, the maximum heating temperature of platinum crucible in use cannot exceed 1200 ℃. Considering the temperature error, it is recommended to use it below 1150 ℃.

2.Do not use too much force when taking the crucible, Too much force will cause the crucible to deform or bump.

3. Special platinum crucible clamp shall be used to take the heated crucible and casting dish (at least the head contacting the crucible clamp be wrapped with platinum).

4.It is recommended not to use manual operation too frequently (i.e. clamp the crucible with crucible tongs for melting, swaying and dumping). frequently manual operation is likely to cause deformation of the crucible and shorten the service life.

5. The heating and burning shall be carried out in the electric furnace or on the oxidation flame of the gas lamp, and the platinum crucible shall not be heated in the reduction flame or the flame emitting black smoke. Or make platinum utensils contact the blue flame core in the flame to prevent the formation of platinum carbide.

6. The crucible shall not contact any other metal (iron plate, electric furnace, etc.) when heating at high temperature, and shall not touch the thermocouple when putting it into the electric furnace.

7. Do not heat molten alkali metal compounds in platinum crucibles.Such as alkali metal oxide, alkali metal hydroxide, alkali metal nitrate, alkali metal nitrite, alkali metal chloride, alkali metal cyanide, etc.

8. The compounds containing heavy metals cannot be burned and heated in the platinum crucible. These heavy metals are easy to be reduced to metal and platinum to form alloys. (These heavy metals include: lead, bismuth, tin, antimony, arsenic, silver, mercury, copper, etc.)

9. The platinum crucible shall not be used to treat halogen and substances that can decompose halogen. Such as aqua regia, bromine water, mixtures of hydrochloric acid and oxidants such as chlorate, nitrate, permanganate, manganese dioxide, chromate, nitrite, and mixtures of halides and oxidants.

10 Ferric chloride has a significant corrosion effect on platinum. After a long time of use, there will be a thin layer of crystals on the surface of platinum utensils, which must be removed in time to prevent them from penetrating into platinum.

11 In the presence of reducing substances (such as filter paper, organic matter in the sample and other substances), it is not allowed to heat or burn substances containing a large amount of phosphorus and sulfur in the platinum crucible to avoid forming brittle platinum phosphide or platinum sulfide with platinum.

12 The sample containing a large amount of iron cannot be directly melted in a platinum crucible. A large amount of iron must be melted with hydrochloric acid first. The residue must be filtered before melting in the crucible. The polymetallic ore sample should be treated with hydrochloric acid and nitric acid first. The residue is incinerated in a porcelain crucible and then transferred to a platinum crucible for melting.

13 Most metals will form alloys with platinum at high temperatures, so metal samples cannot be directly melted in platinum crucibles, and appropriate pre oxidation treatment is required.

14 It is prohibited to heat and burn substances with unknown composition in platinum crucible.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation