Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

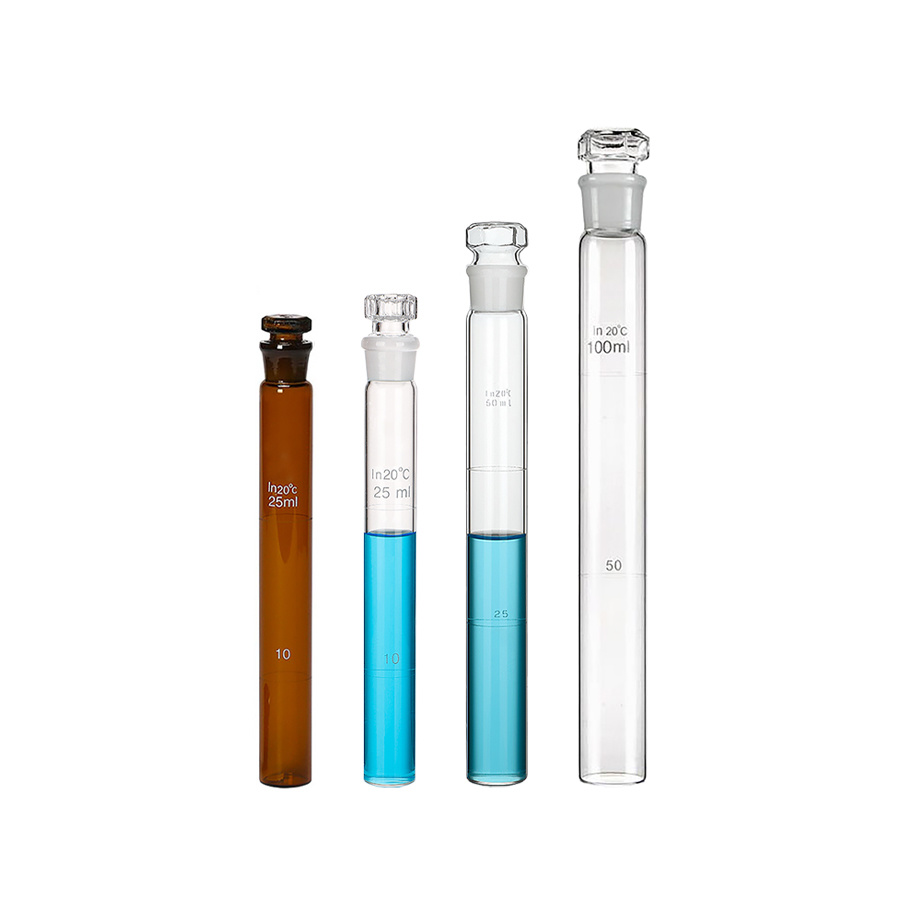

Glass Stopper

Glass Stopper

HG-A,HG-B,HG-C

Brand:

RUISCI

-

Click to select

- HG-A-14,Hollow,14mm

- HG-A-19,Hollow,19mm

- HG-A-24,Hollow,24mm

- HG-A-29,Hollow,29mm

- HG-A-34,Hollow,34mm

- HG-A-40,Hollow,40mm

- HG-A-50,Hollow,50mm

- HG-B-14,Solid,14mm

- HG-B-19,Solid,19mm

- HG-B-24,Solid,24mm

- HG-B-29,Solid,29mm

- HG-C-19,Spherical,19mm

- HG-C-24,Spherical,24mm

- HG-C-29,Spherical,29mm

Inventory

3752

隐藏域元素占位

Overview

Glass stoppers are mainly used for sealing glassware and standard taper apparatus. With fine ground surfaces and precise taper, they are often used as bottle stoppers for various flasks and ground joint instruments.

Features

1. For sealing standard taper apparatus.

2. Standard ground joint with accurate taper.

3. High borosilicate material with stable chemical properties: made of high-quality glass, excellent sealing performance, very low thermal expansion coefficient, and high heat resistance.

4. Spherical stopper: good sealing, interchangeable, reduces the risk of collision, improves experimental efficiency and chemical stability.

5. Solid stopper: suitable for volumetric flasks that need to be soaked in advance for easier cleaning.

Technical data

Precautions:

1. Place the corresponding ground-glass stopper on the corresponding bottle mouth. Do not make it too loose or too tight, as this may cause the stopper to fall off or the bottle mouth to break.

2. Before use, wipe the ground-glass stopper clean with a soft cloth.

3. Apply a small amount of Vaseline or vacuum grease on the surface of the ground-glass to enhance the tightness.

4. When installing, rotate and connect the ground-glass and the ground stopper. Do not apply excessive force.

keyword:

Hollow Glass Stopper

Ground Joint Glass Stopper

Solid Glass Stopper

Glass Stopper for Laboratory Glassware

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Glass Stopper

- Subtitle: Glass Stopper

- Model: HG-A,HG-B,HG-C

- 全部型号: HG-A-14,HG-A-19,HG-A-24,HG-A-29,HG-A-34,HG-A-40,HG-A-50,HG-B-14,HG-B-19,HG-B-24,HG-B-29,HG-C-19,HG-C-24,HG-C-29,

Glass stoppers are mainly used for sealing glassware and standard taper apparatus.

Glass stoppers are mainly used for sealing glassware and standard taper apparatus. With fine ground surfaces and precise taper, they are often used as bottle stoppers for various flasks and ground joint instruments.

-

1. For sealing standard taper apparatus.

2. Standard ground joint with accurate taper.

3. High borosilicate material with stable chemical properties: made of high-quality glass, excellent sealing performance, very low thermal expansion coefficient, and high heat resistance.

4. Spherical stopper: good sealing, interchangeable, reduces the risk of collision, improves experimental efficiency and chemical stability.

5. Solid stopper: suitable for volumetric flasks that need to be soaked in advance for easier cleaning. -

Precautions:

1. Place the corresponding ground-glass stopper on the corresponding bottle mouth. Do not make it too loose or too tight, as this may cause the stopper to fall off or the bottle mouth to break.

2. Before use, wipe the ground-glass stopper clean with a soft cloth.

3. Apply a small amount of Vaseline or vacuum grease on the surface of the ground-glass to enhance the tightness.

4. When installing, rotate and connect the ground-glass and the ground stopper. Do not apply excessive force.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation