Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Vibratory Sieve Shaker

Vibratory Sieve Shaker

RVS-A

Brand:

RUISCI

-

Click to select

- RVS-A-01

Inventory

108

隐藏域元素占位

Overview

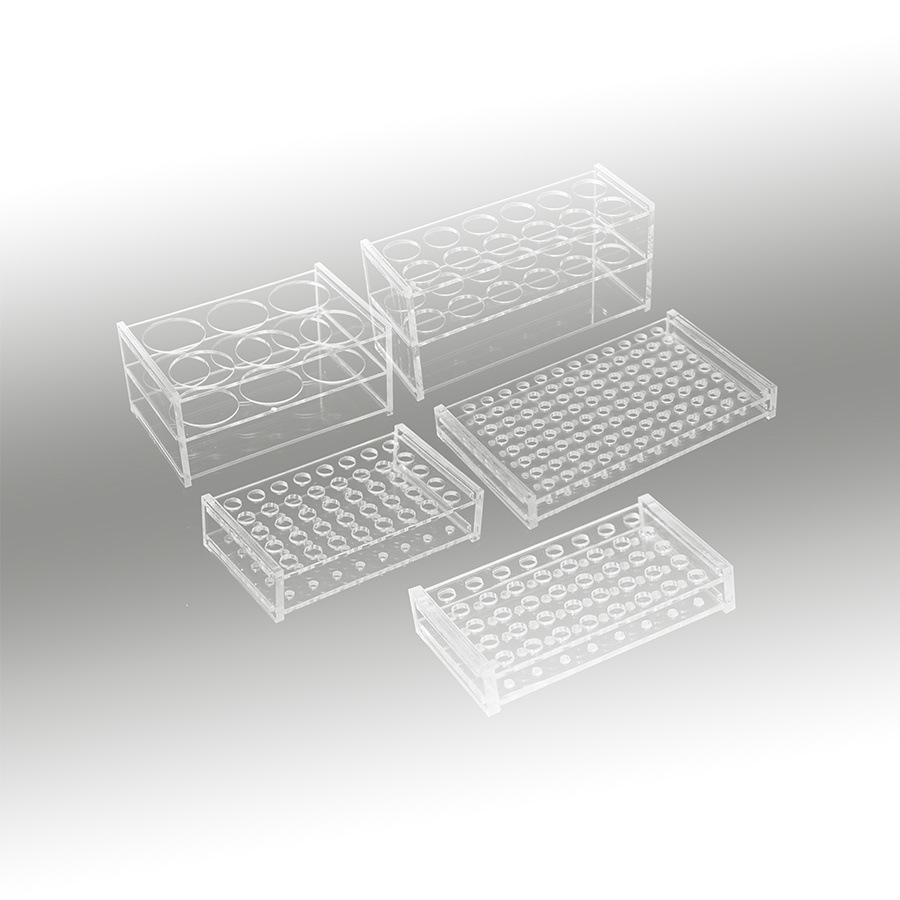

The Vibratory Sieve Shaker is a piece of equipment utilized in laboratories for the sieving and particle size analysis of granular materials. It generates vibrations through a vibration source, enabling the movement of materials on Test Sieves and thereby achieving the separation of particles of diverse particle sizes. It is widely employed in domains such as materials science, chemical engineering, food, pharmaceuticals, and geology, and serves as a crucial tool for particle size analysis and material classification in laboratories.

Features

1. Reinforced on three sides, with small volume and light weight.

2. The structure is simple, and it is convenient to dismantle and replace the Test Sieves.

3. It is provided with a timing function, and the time can be adjusted at any time.

4. It is equipped with an anti-vibration base, which not only lowers the noise but also has the anti-vibration function.

Technical data

Working Environmental Conditions:

1. Temperature: The operating temperature shall be controlled within the range of 5°C to 40°C.

2. Humidity: The relative humidity is suggested to be within 30% to 80%.

3. Power Supply: 220V/50Hz, with proper grounding.

4. Environment: Clean, dry, and free of strong vibration and electromagnetic interference.

5. Placement: On a stable tabletop, avoiding inclination.

Precautions:

1. Sample Preparation: Ensure that the samples are dry and free of agglomeration to avoid influencing the screening accuracy.

2. Sieve Cleaning: The sieve needs to be cleaned before and after use to prevent residues from interfering with the results.

3. Vibration Parameters: Adjust the amplitude and frequency based on the characteristics of the samples to avoid excessive vibration that might damage the equipment or the sieve.

4. Safe Operation: Wear protective equipment and avoid contacting the moving components.

5. Regular Maintenance: Regularly inspect the Test Sieves, the motor, and the fasteners to ensure the normal operation of the equipment.

7. Abnormal Handling: If abnormal sounds or vibrations occur during operation, the machine should be stopped immediately for inspection.

keyword:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Vibratory Sieve Shaker

- Subtitle: Vibratory Sieve Shaker

- Model: RVS-A

- 全部型号: RVS-A-01

The Vibratory Sieve Shaker is a piece of equipment utilized in laboratories for the sieving and particle size analysis of granular materials.

The Vibratory Sieve Shaker is a piece of equipment utilized in laboratories for the sieving and particle size analysis of granular materials. It generates vibrations through a vibration source, enabling the movement of materials on Test Sieves and thereby achieving the separation of particles of diverse particle sizes. It is widely employed in domains such as materials science, chemical engineering, food, pharmaceuticals, and geology, and serves as a crucial tool for particle size analysis and material classification in laboratories.

-

1. Reinforced on three sides, with small volume and light weight.

2. The structure is simple, and it is convenient to dismantle and replace the Test Sieves.

3. It is provided with a timing function, and the time can be adjusted at any time.

4. It is equipped with an anti-vibration base, which not only lowers the noise but also has the anti-vibration function. -

Working Environmental Conditions:

1. Temperature: The operating temperature shall be controlled within the range of 5°C to 40°C.

2. Humidity: The relative humidity is suggested to be within 30% to 80%.

3. Power Supply: 220V/50Hz, with proper grounding.

4. Environment: Clean, dry, and free of strong vibration and electromagnetic interference.

5. Placement: On a stable tabletop, avoiding inclination.

Precautions:

1. Sample Preparation: Ensure that the samples are dry and free of agglomeration to avoid influencing the screening accuracy.

2. Sieve Cleaning: The sieve needs to be cleaned before and after use to prevent residues from interfering with the results.

3. Vibration Parameters: Adjust the amplitude and frequency based on the characteristics of the samples to avoid excessive vibration that might damage the equipment or the sieve.

4. Safe Operation: Wear protective equipment and avoid contacting the moving components.

5. Regular Maintenance: Regularly inspect the Test Sieves, the motor, and the fasteners to ensure the normal operation of the equipment.

7. Abnormal Handling: If abnormal sounds or vibrations occur during operation, the machine should be stopped immediately for inspection.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation