Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Soil Drying Oven

Soil Drying Oven

RSD-A

Brand:

RUISCI

-

Click to select

- RSD-A-24,Separate

- RSD-A-24A,Overall

- RSD-A-12,Separate

- RSD-A-12A,Overall

Inventory

672

隐藏域元素占位

Overview

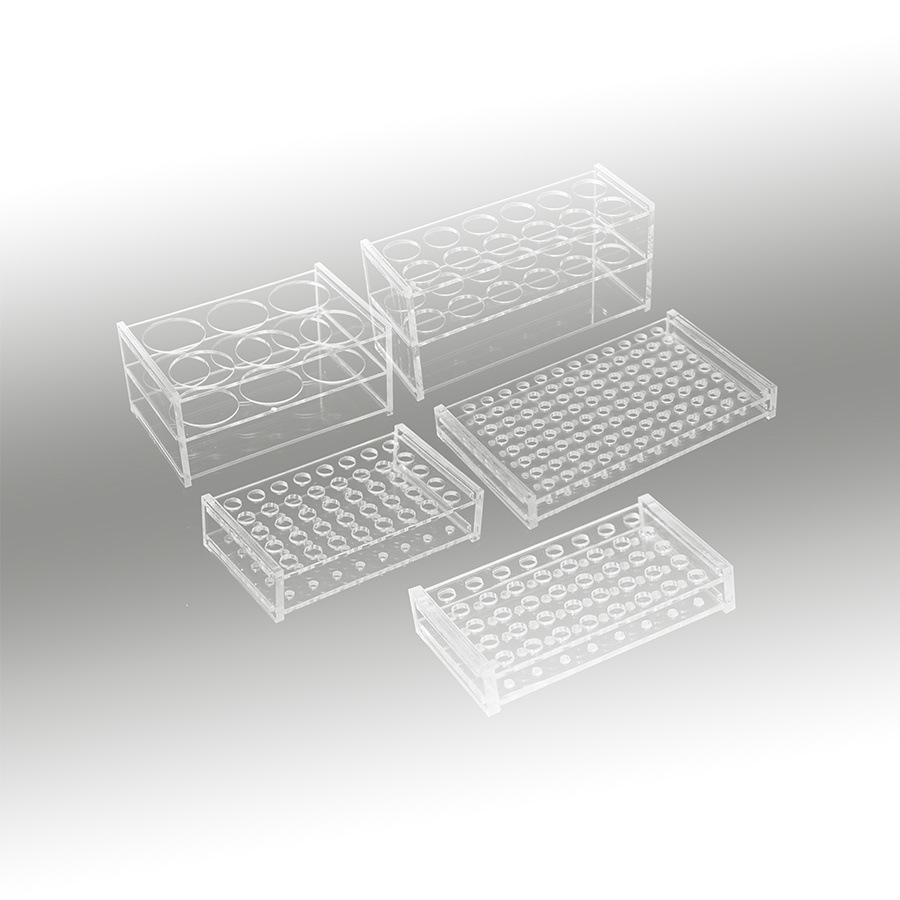

The Soil Drying Oven adopts the simulation of the indoor air flow pattern, namely the air-drying mode, for soil drying. The drying air is clean hot air that has undergone coarse filtration and activated carbon adsorption. Samples are independently stored and dried in separate compartments. It possesses the characteristics of cleanliness, avoidance of cross-contamination among samples, time-saving, labor-saving, space-saving, and improvement of soil drying efficiency.

Features

1. The soil, sediment and solid waste samples utilized for heavy metal analysis are dried through the sample heating and air drying technology, enhancing the efficiency of air drying the samples.

2. The independent 12/24-position Sample Room segregates the samples to prevent cross-contamination.

3. The air perturbation technology is employed to simulate the indoor air flow, approximating the indoor environment to the greatest extent and attaining the objective of rapid air drying.

4. The transparent window lighting design facilitates observation.

5. The Sample Room is fabricated from 304 stainless steel to avoid chemical corrosion and organic matter adsorption, and is readily cleanable and maintainable.

6. Universal casters are installed at the bottom for facile movement.

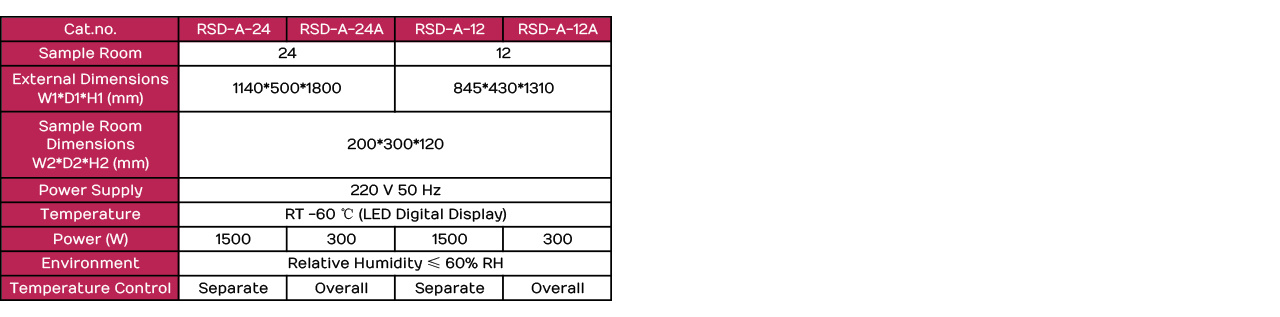

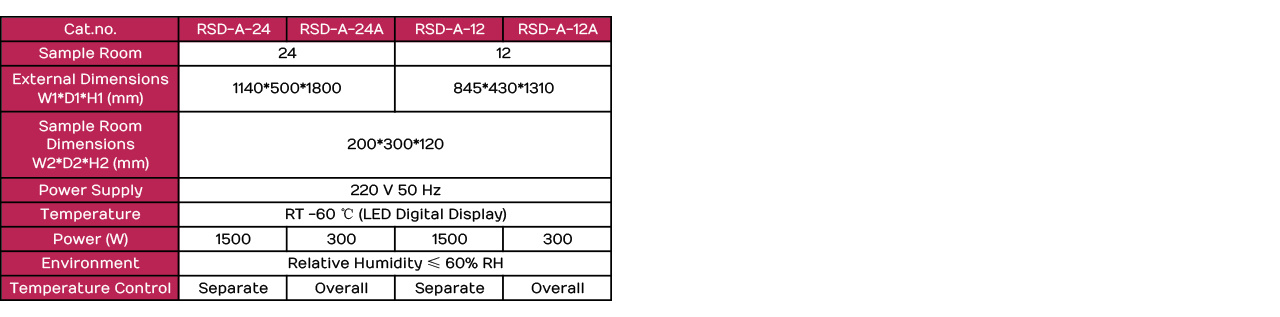

Technical data

Working Environment Conditions:

1. Humidity Control: The relative humidity should be no more than 60% RH.

2. Airflow: Internal circulating fans ensure uniform drying.

Precautions:

1. Do not disassemble it randomly during usage; otherwise, it will lead to system leakage and affect normal operation.

2. Clean it immediately after use to prevent residual soil samples from remaining in the sample chamber and causing secondary contamination during the next drying process.

3. When the sample does not require heating, the corresponding "temperature switch" of the sample chamber can be turned off.

4. Do not blow towards the front of the entire machine with a fan to prevent air backflow in the Sample Room and resultant secondary contamination.

5. The gas source and heating can be utilized independently. However, if the gas source is shut off and direct heating is employed, the uniformity of the sample chamber will be reduced, and the soil samples will not be dried uniformly.

keyword:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Soil Drying Oven

- Subtitle: Soil Drying Oven

- Model: RSD-A

- 全部型号: RSD-A-24,RSD-A-24A,RSD-A-12,RSD-A-12A

The Soil Drying Oven adopts the simulation of the indoor air flow pattern, namely the air-drying mode, for soil drying.

The Soil Drying Oven adopts the simulation of the indoor air flow pattern, namely the air-drying mode, for soil drying. The drying air is clean hot air that has undergone coarse filtration and activated carbon adsorption. Samples are independently stored and dried in separate compartments. It possesses the characteristics of cleanliness, avoidance of cross-contamination among samples, time-saving, labor-saving, space-saving, and improvement of soil drying efficiency.

-

1. The soil, sediment and solid waste samples utilized for heavy metal analysis are dried through the sample heating and air drying technology, enhancing the efficiency of air drying the samples.

2. The independent 12/24-position Sample Room segregates the samples to prevent cross-contamination.

3. The air perturbation technology is employed to simulate the indoor air flow, approximating the indoor environment to the greatest extent and attaining the objective of rapid air drying.

4. The transparent window lighting design facilitates observation.

5. The Sample Room is fabricated from 304 stainless steel to avoid chemical corrosion and organic matter adsorption, and is readily cleanable and maintainable.

6. Universal casters are installed at the bottom for facile movement. -

Working Environment Conditions:

1. Humidity Control: The relative humidity should be no more than 60% RH.

2. Airflow: Internal circulating fans ensure uniform drying.Precautions:

1. Do not disassemble it randomly during usage; otherwise, it will lead to system leakage and affect normal operation.

2. Clean it immediately after use to prevent residual soil samples from remaining in the sample chamber and causing secondary contamination during the next drying process.

3. When the sample does not require heating, the corresponding "temperature switch" of the sample chamber can be turned off.

4. Do not blow towards the front of the entire machine with a fan to prevent air backflow in the Sample Room and resultant secondary contamination.

5. The gas source and heating can be utilized independently. However, if the gas source is shut off and direct heating is employed, the uniformity of the sample chamber will be reduced, and the soil samples will not be dried uniformly.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation