Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Tube Furnace

Tube Furnace

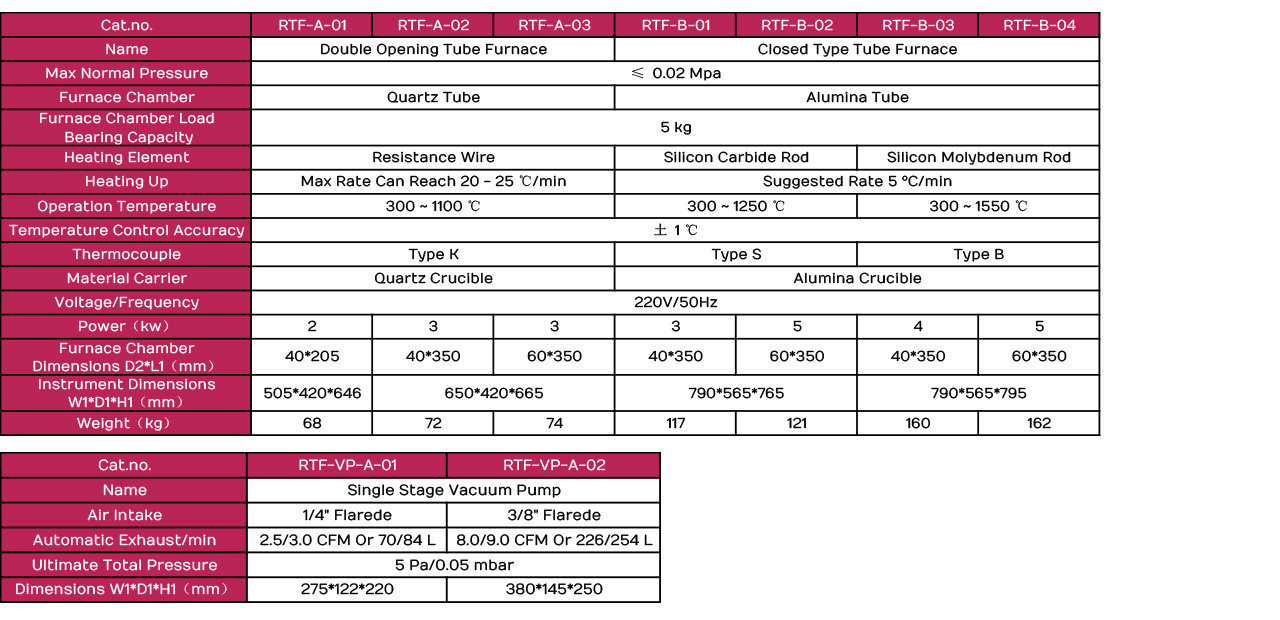

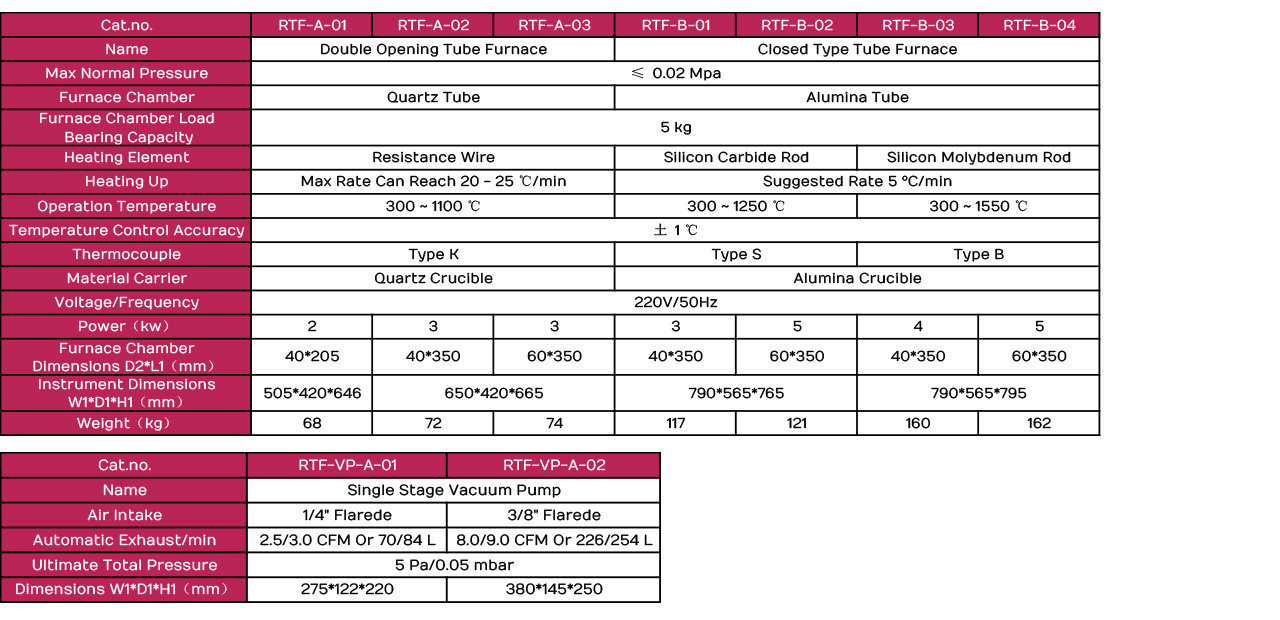

RTF-A,RTF-B

Brand:

RUISCI

-

Click to select

- RTF-A-01,Double Opening

- RTF-A-02,Double Opening

- RTF-A-03,Double Opening

- RTF-B-01,Closed

- RTF-B-02,Closed

- RTF-B-03,Closed

- RTF-B-04,Closed

- RTF-VP-A-01,1/4" Flarede,Single Stage Vacuum Pump

- RTF-VP-A-02,3/8" Flarede,Single Stage Vacuum Pump

Inventory

1512

隐藏域元素占位

Overview

The Tube Furnace is a heating equipment employed in domains like materials science and chemistry, possessing characteristics such as precise temperature control and uniform heating. It is capable of operating under diverse atmospheres, such as air, inert gases or vacuum circumstances, and is applicable to material synthesis, heat treatment and catalytic reaction research, etc.

Features

1. The intelligent control instrument enables slope heating and cooling, with 30 segments of program settings.

2. The furnace chamber of alumina ceramic fiber and the ceramic fiber inner liner are resistant to extreme cold and heat without cracking or combustion.

3. The double-layer air-cooled furnace body reduces the surface temperature of the furnace body, ensuring greater stability and safety.

4. Safety protection functions include over-temperature protection, temperature deviation protection, open-couple indication, and the standard air circuit breaker is equipped.

5. The 304 stainless steel flange seal is corrosion-resistant, oxidation-resistant, and has strong sealing performance.

6. A variety of gases can be passed through, including all inert gases and mixed gases, such as nitrogen, oxygen, carbon monoxide, chlorine, etc.

7.Silicon Carbon Rods or Silicon Molybdenum Rods are used for heating, featuring high thermal conductivity, high-temperature resistance, and low deformation.

Technical data

Working environment conditions:

1. The altitude must not exceed 1000m.

2. The ambient temperature should range from -10 to 75℃.

3. The average monthly relative humidity in the applicable region should not be greater than 85%.

4. There should be no conductive dust, explosive gases, or corrosive gases that can severely damage metals and insulation around the furnace.

5. There should be no significant vibration or jolt.

Precautions:

1. When operating the electric furnace, the furnace temperature must not exceed the rated temperature to avoid damaging the heating elements. It is strictly forbidden to directly pour various liquids and molten metals into the furnace chamber. Regularly remove iron filings and oxides from the furnace chamber to maintain its cleanliness.

2. Regularly inspect the electric furnace and check whether the contacts of each connection part of the temperature controller and the conductive system are in good condition.

3. Safety protection: Wear appropriate protective gear.

4. Careful handling: Handle with caution to avoid severe vibration and collision.

5. The properties of S-type and B-type thermocouples do not permit their application in environments with high hydrogen, high carbon, and high silicon contents, as they are susceptible to corrosion and damage.

6. For furnaces with quartz tubes as the material, when utilized for the first time or after a prolonged period of non-use, they should be baked at approximately 200°C for 2 hours, followed by another 2 hours at around 300°C prior to operation, in order to avoid cracking of the furnace chamber.

7. For furnaces with corundum tubes, when employed for the first time or after an extended period of disuse, they should be baked at around 300 - 400°C for 5 - 6 hours to prevent cracking of the furnace chamber.

8. The recommended heating rate for corundum tubes is 10°C/min when the temperature is below 1000°C; no more than 5°C/min when the temperature is between 1000 - 1500°C; and no more than 2°C/min when the temperature is above 1500°C. Otherwise, it may cause damage to the furnace chamber, heating elements, and tubes.

9. Corundum tubes should not be operated under negative pressure at temperatures exceeding 1000°C, and quartz tubes should not be operated under negative pressure at temperatures exceeding 800°C.

10. The furnace body adopts silicon molybdenum rods as the heating elements and is not suitable for prolonged operation within the temperature range of 400 - 700°C. Otherwise, low-temperature oxidation of the silicon molybdenum rods may occur, resulting in component damage.

keyword:

Analysis of Tube Furnace

Vertical

Horizontal

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Tube Furnace

- Subtitle: Tube Furnace

- Model: RTF-A,RTF-B

- 全部型号: Horizontal,Vertical,Analysis of Tube Furnace,RTF-A-01,RTF-A-02,RTF-A-03,RTF-B-01,RTF-B-02, RTF-B-03,RTF-B-04

The Tube Furnace is a heating equipment employed in domains like materials science and chemistry, possessing characteristics such as precise temperature control and uniform heating.

The Tube Furnace is a heating equipment employed in domains like materials science and chemistry, possessing characteristics such as precise temperature control and uniform heating. It is capable of operating under diverse atmospheres, such as air, inert gases or vacuum circumstances, and is applicable to material synthesis, heat treatment and catalytic reaction research, etc.

-

1. The intelligent control instrument enables slope heating and cooling, with 30 segments of program settings.

2. The furnace chamber of alumina ceramic fiber and the ceramic fiber inner liner are resistant to extreme cold and heat without cracking or combustion.

3. The double-layer air-cooled furnace body reduces the surface temperature of the furnace body, ensuring greater stability and safety.

4. Safety protection functions include over-temperature protection, temperature deviation protection, open-couple indication, and the standard air circuit breaker is equipped.

5. The 304 stainless steel flange seal is corrosion-resistant, oxidation-resistant, and has strong sealing performance.

6. A variety of gases can be passed through, including all inert gases and mixed gases, such as nitrogen, oxygen, carbon monoxide, chlorine, etc.

7.Silicon Carbon Rods or Silicon Molybdenum Rods are used for heating, featuring high thermal conductivity, high-temperature resistance, and low deformation. -

Working environment conditions:

1. The altitude must not exceed 1000m.

2. The ambient temperature should range from -10 to 75℃.

3. The average monthly relative humidity in the applicable region should not be greater than 85%.

4. There should be no conductive dust, explosive gases, or corrosive gases that can severely damage metals and insulation around the furnace.

5. There should be no significant vibration or jolt.Precautions:

1. When operating the electric furnace, the furnace temperature must not exceed the rated temperature to avoid damaging the heating elements. It is strictly forbidden to directly pour various liquids and molten metals into the furnace chamber. Regularly remove iron filings and oxides from the furnace chamber to maintain its cleanliness.

2. Regularly inspect the electric furnace and check whether the contacts of each connection part of the temperature controller and the conductive system are in good condition.

3. Safety protection: Wear appropriate protective gear.

4. Careful handling: Handle with caution to avoid severe vibration and collision.

5. The properties of S-type and B-type thermocouples do not permit their application in environments with high hydrogen, high carbon, and high silicon contents, as they are susceptible to corrosion and damage.

6. For furnaces with quartz tubes as the material, when utilized for the first time or after a prolonged period of non-use, they should be baked at approximately 200°C for 2 hours, followed by another 2 hours at around 300°C prior to operation, in order to avoid cracking of the furnace chamber.

7. For furnaces with corundum tubes, when employed for the first time or after an extended period of disuse, they should be baked at around 300 - 400°C for 5 - 6 hours to prevent cracking of the furnace chamber.

8. The recommended heating rate for corundum tubes is 10°C/min when the temperature is below 1000°C; no more than 5°C/min when the temperature is between 1000 - 1500°C; and no more than 2°C/min when the temperature is above 1500°C. Otherwise, it may cause damage to the furnace chamber, heating elements, and tubes.

9. Corundum tubes should not be operated under negative pressure at temperatures exceeding 1000°C, and quartz tubes should not be operated under negative pressure at temperatures exceeding 800°C.

10. The furnace body adopts silicon molybdenum rods as the heating elements and is not suitable for prolonged operation within the temperature range of 400 - 700°C. Otherwise, low-temperature oxidation of the silicon molybdenum rods may occur, resulting in component damage.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation