Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

V-Type Mixer

V-Type Mixer

RVH-A,RVH-B

Brand:

RUISCI

-

Click to select

- RVH-A-01,Single,0.6L

- RVH-A-02,Single,2L

- RVH-A-03,Single,3.2L

- RVH-A-04,Single,5.6L

- RVH-A-05,Single,8L

- RVH-A-06,Single,12L

- RVH-B-01,Dual,12L

Inventory

1176

隐藏域元素占位

Overview

The V-type mixer is a highly efficient asymmetric mixing equipment. Owing to the different lengths of the two cylinders, an asymmetric flow of materials is created, causing the materials to repeatedly alternate, divide, and merge within the cylinders. The material randomly flows from one cylinder to the other, while sliding occurs between powder particles, enabling multiple spatial overlays. Through repeated shearing and diffusion movements, uniform mixing is ultimately achieved.

Features

1. It is made of 304 stainless steel material, which endows it with excellent corrosion resistance. It features low noise during operation, high durability, aesthetic appearance, and easy cleaning.

2. V-shaped design enables dual-end loading providing with high homogeneity, and complete discharge without residue.

3. The sealing ring design effectively guarantees a good sealing performance.

4. It is equipped with a control system that enables speed adjustment and timing functions.

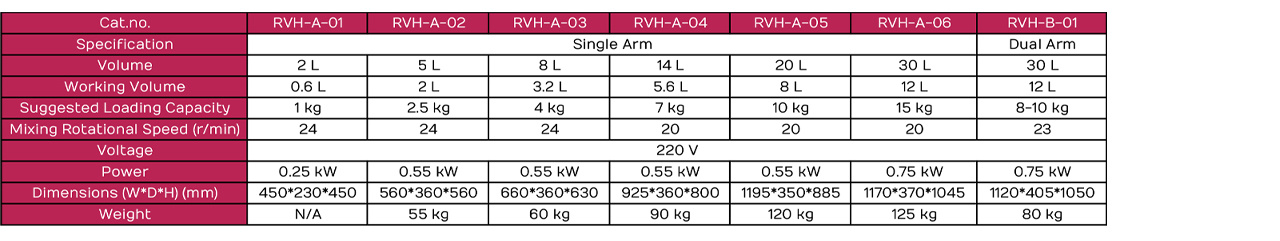

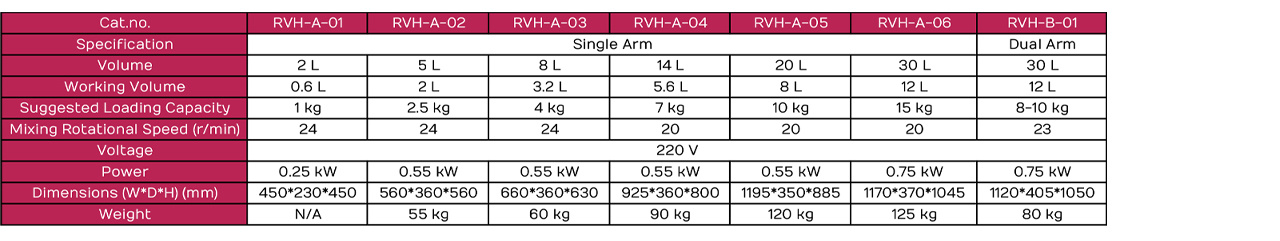

Technical data

Precautions:

1. Ascertain that the equipment exhibits no damage or deformation, and that the fasteners are free from looseness. Confirm that the interior of the mixer is devoid of foreign objects and that the inner wall of the hopper is dry.

2. Inspect all sealing gaskets between cylinders and at discharge ports for integrity - ensure no aging, cracks, or deformation. Verify all fastening bolts are properly torqued to maintain leak-proof performance.

3. In strict accordance with the rated volume of the equipment and the properties of the materials, precisely control the feeding quantity. As a general guideline, it is advisable that the feeding amount does not exceed 70% - 80% of the cylinder volume. This approach ensures optimal mixing efficiency and the efficient operation of the equipment.

4. The equipment should be installed on a flat and solid surface to ensure stability during operation. An uneven surface may lead to exacerbated vibrations of the equipment, which can potentially compromise the mixing efficiency and reduce the lifespan of the equipment.

5. If abnormal sound, vibrations, high temperature, or motor overload during operation, it should be stopped immediately for inspection.

6. After each use or when switching to a different material for mixing, it is imperative to conduct a thorough cleaning of the equipment. Utilize a clean soft cloth or sponge to wipe the inner and outer walls of the cylinder, ensuring the complete removal of any material residues.

7. When operating the mixer, appropriate personal protective equipment, such as laboratory safety goggles and gloves, should be worn.

keyword:

V-Type Mixer

V-Shaped Mixer

V Blender

V Cone Mixer

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: V-Type Mixer

- Subtitle: V-Type Mixer

- Model: RVH-A,RVH-B

- 全部型号: RVH-A-01,RVH-A-02,RVH-A-03,RVH-A-04,RVH-A-05,RVH-A-06,RVH-B-01,V-Shaped Mixer,V Blender,V Cone Mixer

The V-type mixer is a highly efficient asymmetric mixing equipment.

The V-type mixer is a highly efficient asymmetric mixing equipment. Owing to the different lengths of the two cylinders, an asymmetric flow of materials is created, causing the materials to repeatedly alternate, divide, and merge within the cylinders. The material randomly flows from one cylinder to the other, while sliding occurs between powder particles, enabling multiple spatial overlays. Through repeated shearing and diffusion movements, uniform mixing is ultimately achieved.

-

1. It is made of 304 stainless steel material, which endows it with excellent corrosion resistance. It features low noise during operation, high durability, aesthetic appearance, and easy cleaning.

2. V-shaped design enables dual-end loading providing with high homogeneity, and complete discharge without residue.

3. The sealing ring design effectively guarantees a good sealing performance.

4. It is equipped with a control system that enables speed adjustment and timing functions. -

Precautions:

1. Ascertain that the equipment exhibits no damage or deformation, and that the fasteners are free from looseness. Confirm that the interior of the mixer is devoid of foreign objects and that the inner wall of the hopper is dry.

2. Inspect all sealing gaskets between cylinders and at discharge ports for integrity - ensure no aging, cracks, or deformation. Verify all fastening bolts are properly torqued to maintain leak-proof performance.

3. In strict accordance with the rated volume of the equipment and the properties of the materials, precisely control the feeding quantity. As a general guideline, it is advisable that the feeding amount does not exceed 70% - 80% of the cylinder volume. This approach ensures optimal mixing efficiency and the efficient operation of the equipment.

4. The equipment should be installed on a flat and solid surface to ensure stability during operation. An uneven surface may lead to exacerbated vibrations of the equipment, which can potentially compromise the mixing efficiency and reduce the lifespan of the equipment.

5. If abnormal sound, vibrations, high temperature, or motor overload during operation, it should be stopped immediately for inspection.

6. After each use or when switching to a different material for mixing, it is imperative to conduct a thorough cleaning of the equipment. Utilize a clean soft cloth or sponge to wipe the inner and outer walls of the cylinder, ensuring the complete removal of any material residues.

7. When operating the mixer, appropriate personal protective equipment, such as laboratory safety goggles and gloves, should be worn.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation