Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Coating Thickness Gauge

Coating Thickness Gauge

RCTG-A,RCTG-B

Brand:

RUISCI

-

Click to select

- RCTG-A-01

- RCTG-A-02

- RCTG-B-01

- RCTG-B-02

- RCTG-B-03

- RCTG-B-04

- RCTG-B-05

Inventory

1176

隐藏域元素占位

Overview

Coating thickness gauge is an instrument used to measure the thickness of coatings on the surface of objects. It can quickly, non-destructively and accurately measure the thickness of coatings through different measurement principles, thereby ensuring the quality and performance of the coatings. It is widely used in manufacturing, metal processing, chemical industry, commodity inspection and other inspection fields.

Features

Features of RCTG-A Coating Thickness Gauge:

1. The integrated design allows one-handed operation, ideal for routine testing scenarios, while the external probe version accommodates measurements in confined spaces.

2. Featuring digital probe technology with drift-free zero positioning, this gauge requires no calibration - simply perform a quick zero adjustment for precise measurements.

3. The auto-recognition system instantly identifies ferrous metals, non-ferrous metals, or non-metallic substrates within 0.5 seconds, delivering rapid response measurements in just 0.5 seconds per reading.

4. Our temperature compensation technology maintains measurement accuracy across varying environmental temperatures.

5. The wear-resistant ruby probe tip ensures extended service life and consistent performance.

6. Capable of measuring coating thickness on ultra-thin substrates with high precision.

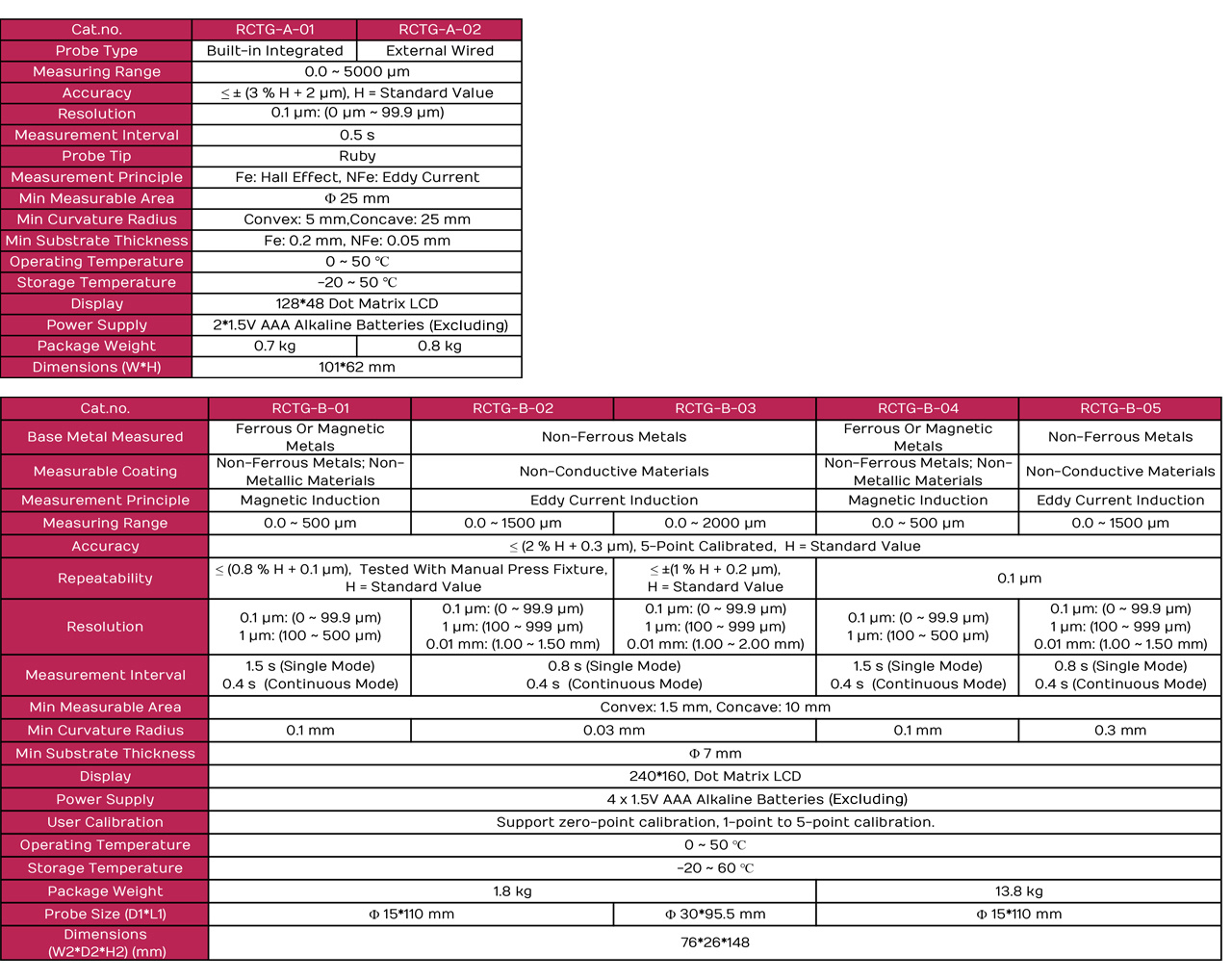

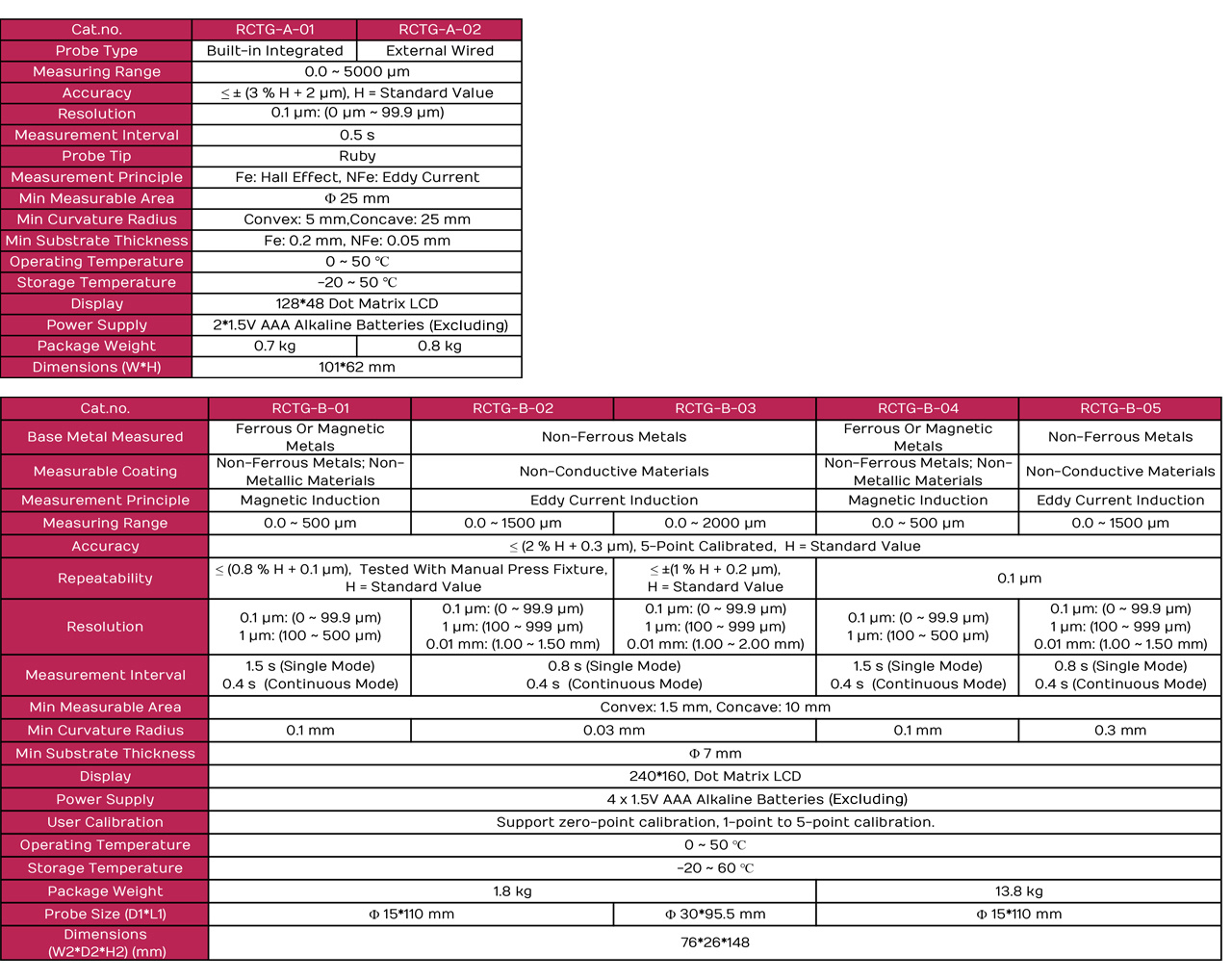

Technical data

Precautions:

1. The measurement must be performed with point contact. Sliding the probe across the test surface is strictly prohibited.

2. During measurement, the probe must be centered over the point to be measured. The outer edge of the probe should not extend beyond the surface being measured.

3. Conduct measurements at a distance from strong magnetic sources (such as magnets and speakers) and intense electromagnetic fields (such as transformers and induction cookers).

4. Prior to using the instrument, it is advisable to perform a zero - setting operation.

5. Ensure that the test surface is clean. Dust, dirt, and other contaminants on the measurement surface can affect the accuracy of the measurement results.

6. When the instrument indicates "low battery", replace the batteries with new ones.

7. For the RRK - B model of the coating thickness gauge, it is recommended to perform multi - point calibration before use.

8. The instrument exhibits the best stability in the single - measurement mode. For precise measurements, the single - measurement mode is recommended.

9. Due to factors such as surface roughness, dust, and scratches on the workpiece, the instrument may not display 0 μm when measuring the same position again after zero - setting. Correct and proficient operation of the instrument is essential; otherwise, it may lead to unstable measurement values.

keyword:

Coating Thickness Gauge

Coating Thickness Measuring Instrument

Galvanized Coating Thickness Gauge

Digital Paint Coating Thickness Gauge

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Coating Thickness Gauge

- Subtitle: Coating Thickness Gauge

- Model: RCTG-A,RCTG-B

- 全部型号: RCTG-A-01,RCTG-A-02,RCTG-B-01,RCTG-B-02,RCTG-B-03,RCTG-B-04,RCTG-B-05,Coating Thickness Gauge,Coating Thickness Measuring Instrument,Galvanized Coating Thickness Gauge,Digital Paint Coating Thickness Gauge

Coating thickness gauge is an instrument used to measure the thickness of coatings on the surface of objects.

Coating thickness gauge is an instrument used to measure the thickness of coatings on the surface of objects. It can quickly, non-destructively and accurately measure the thickness of coatings through different measurement principles, thereby ensuring the quality and performance of the coatings. It is widely used in manufacturing, metal processing, chemical industry, commodity inspection and other inspection fields.

-

Features of RCTG-A Coating Thickness Gauge:

1. The integrated design allows one-handed operation, ideal for routine testing scenarios, while the external probe version accommodates measurements in confined spaces.

2. Featuring digital probe technology with drift-free zero positioning, this gauge requires no calibration - simply perform a quick zero adjustment for precise measurements.

3. The auto-recognition system instantly identifies ferrous metals, non-ferrous metals, or non-metallic substrates within 0.5 seconds, delivering rapid response measurements in just 0.5 seconds per reading.

4. Our temperature compensation technology maintains measurement accuracy across varying environmental temperatures.

5. The wear-resistant ruby probe tip ensures extended service life and consistent performance.

6. Capable of measuring coating thickness on ultra-thin substrates with high precision. -

Precautions:

1. The measurement must be performed with point contact. Sliding the probe across the test surface is strictly prohibited.

2. During measurement, the probe must be centered over the point to be measured. The outer edge of the probe should not extend beyond the surface being measured.

3. Conduct measurements at a distance from strong magnetic sources (such as magnets and speakers) and intense electromagnetic fields (such as transformers and induction cookers).

4. Prior to using the instrument, it is advisable to perform a zero - setting operation.

5. Ensure that the test surface is clean. Dust, dirt, and other contaminants on the measurement surface can affect the accuracy of the measurement results.

6. When the instrument indicates "low battery", replace the batteries with new ones.

7. For the RRK - B model of the coating thickness gauge, it is recommended to perform multi - point calibration before use.

8. The instrument exhibits the best stability in the single - measurement mode. For precise measurements, the single - measurement mode is recommended.

9. Due to factors such as surface roughness, dust, and scratches on the workpiece, the instrument may not display 0 μm when measuring the same position again after zero - setting. Correct and proficient operation of the instrument is essential; otherwise, it may lead to unstable measurement values.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation