Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Li2B4O7,Lithium Tetraborate,Flux,12007-60-2

Li2B4O7,Lithium Tetraborate,Flux,12007-60-2

R-FL-T

-

Click to select

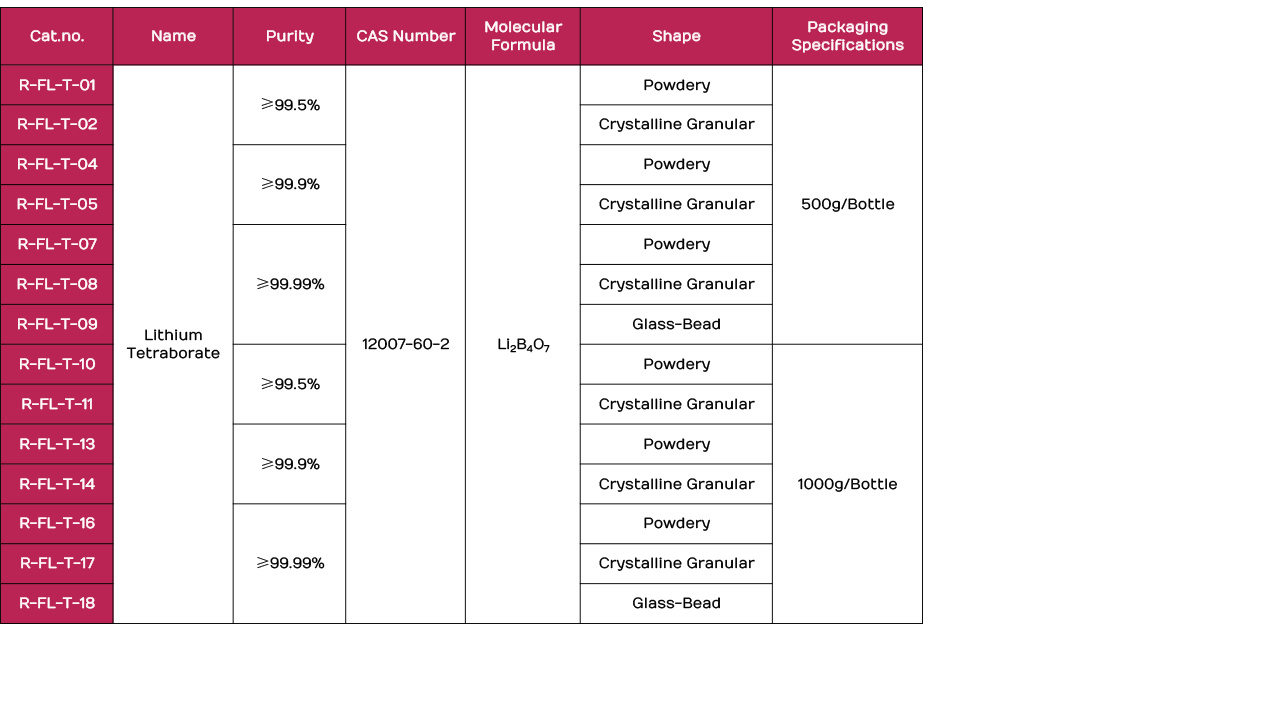

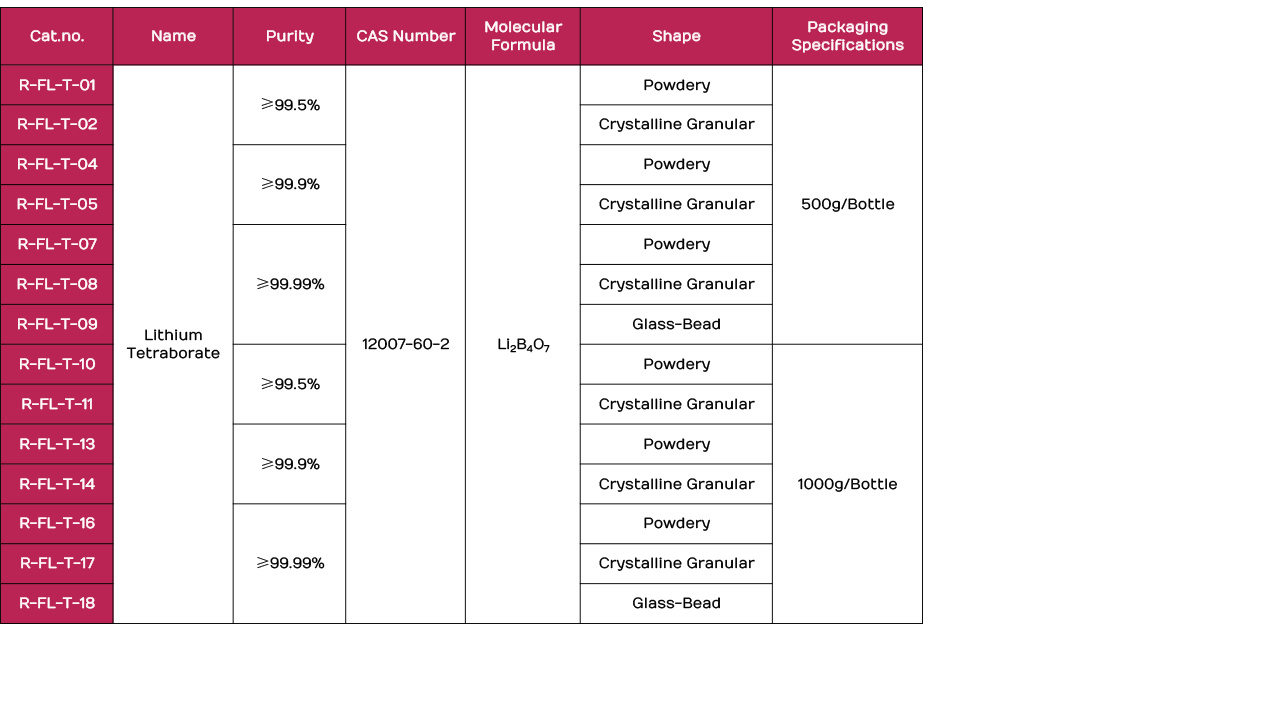

- R-FL-T-01,≥99.5%,Powdery,500g

- R-FL-T-02,≥99.5%,Crystalline Granular,500g

- R-FL-T-04,≥99.9%,Powdery,500g

- R-FL-T-05,≥99.9%,Crystalline Granular,500g

- R-FL-T-07,≥99.99%,Powdery,500g

- R-FL-T-08,≥99.99%,Crystalline Granular,500g

- R-FL-T-09,≥99.99%,Glass-Bead,500g

- R-FL-T-10,≥99.5%,Powdery,1000g

- R-FL-T-11,≥99.5%,Crystalline Granular,1000g

- R-FL-T-13,≥99.9%,Powdery,1000g

- R-FL-T-14,≥99.9%,Crystalline Granular,1000g

- R-FL-T-16,≥99.99%,Powdery,1000g

- R-FL-T-17,≥99.99%,Crystalline Granular,1000g

- R-FL-T-18,≥99.99%,Glass-Bead,1000g

Inventory

15554

隐藏域元素占位

Overview

Flux is a type of chemical reagent capable of reducing the melting point of substances and is commonly employed to promote the melting and crystallization processes of materials at relatively low temperatures. Its primary role is to form a low-melting-point eutectic with the reactants, enhancing the fluidity of the reactants, thereby accelerating the rate of chemical reactions and elevating the purity of the reaction products. Flux usually possess excellent thermal stability and chemical inertness to avoid adverse reactions with the reactants.

The RUISCI Flux is fabricated using meticulously selected high-purity raw materials and preprocessed into glass bead and crystal particle forms through an exclusive blending and synthesis technique. It exhibits uniform particles, is pollution-free, facile to use, and offers excellent application performance (requiring no calcination), thereby providing greater analytical accuracy. It can be employed for the preparation of fused glass wafers and simultaneously effectively prolongs the lifespan of platinum yellowware and fusion apparatuses. It conforms to the requirements for Flux stipulated in multiple standards such as ISO 12677 and is extensively utilized in instrumental analyses (XRF, ICP, AAS) as well as wet chemical analyses.

Features

1. The relatively low melting point can effectively reduce the melting point of the reaction system, converting the solid-phase reaction into a liquid-solid two-phase reaction, thereby facilitating the dissolution of reactants and the advancement of the reaction.

2. Excellent dissolution capability enables it to dissolve the refractory components in the reactants, enhancing the reaction rate and the purity of the product.

3. Exhibiting chemical inertness at high temperatures, it does not undergo adverse reactions with the reactants to avoid the introduction of impurities.

4. Possessing low volatility to minimize losses at high temperatures and pollution to the experimental environment.

5. The particles are uniform, pollution-free, and of high purity.

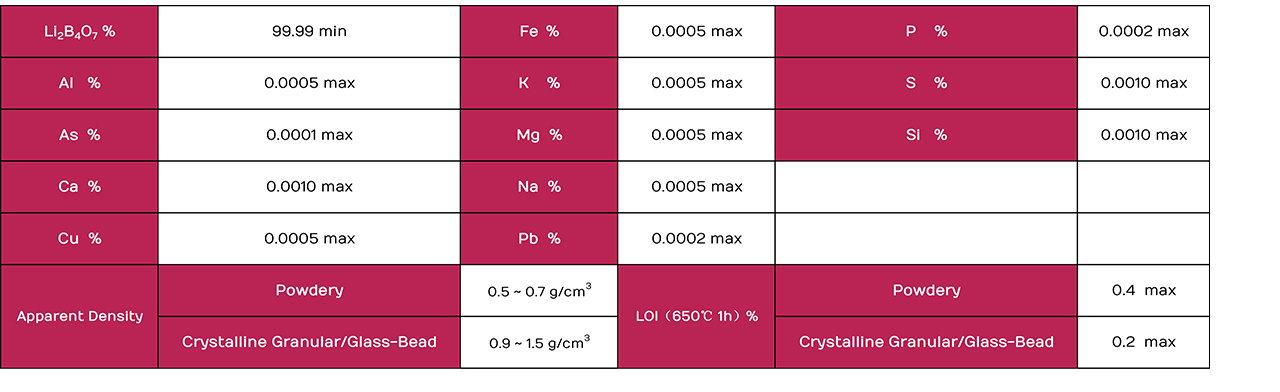

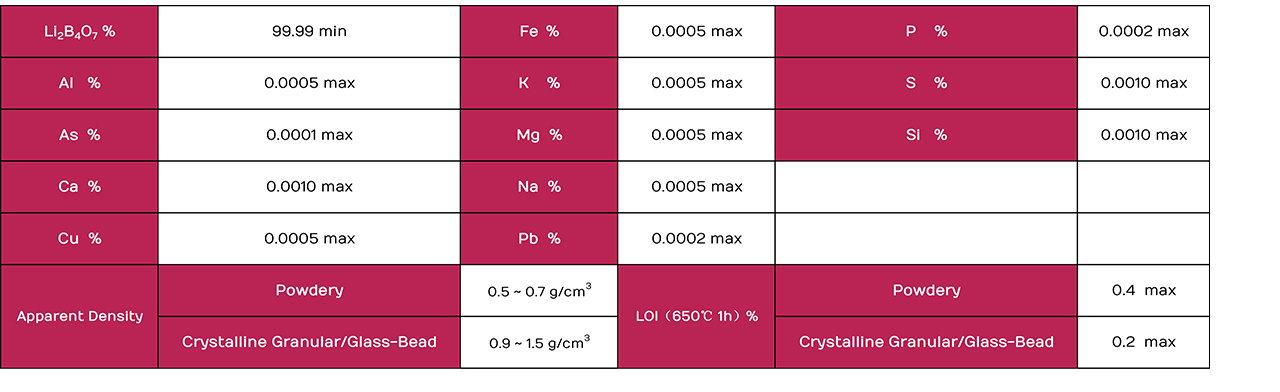

Technical data

Working Environment Conditions:

1. Personal Protection: When manipulating fluxes, appropriate personal protective equipment such as laboratory safety glasses, protective gloves, and protective clothing should be worn.

2. Inhalation Avoidance: During the handling of fluxes, inhalation of their dust or fumes should be avoided. Work in a well-ventilated setting and utilize local exhaust equipment when necessary.

3. Skin Contact: In case flux accidentally comes into contact with the skin, immediate rinsing with copious amounts of water is necessary and medical assistance should be sought.

4. Eye Contact: If flux enters the eyes, immediate rinsing of the eyes with copious amounts of water for at least 15 minutes is required, and medical attention should be sought promptly.

5. Storage Conditions: Fluxes should be kept in a dry, cool, and well-ventilated location, distant from heat and fire sources.

6. Labels and Documentation: Ensure that all flux containers are distinctly labeled, indicating the contents, hazard level, and safety instructions for usage.

7. Usage Quantity: The use of fluxes should be strictly in accordance with experimental requirements and excessive usage should be avoided.

8. Waste Disposal: Waste fluxes after utilization should be dealt with in accordance with laboratory waste disposal regulations and must not be disposed of randomly.

9. Equipment Inspection: Prior to the use of fluxes, it is necessary to inspect whether all equipment intended for use with fluxes is in good condition.

10. Operating Procedures: Adhere to the laboratory's operating procedures and safety guidelines to ensure the safety of experiments.

11. Training and Education: Ensure that all personnel using fluxes have received appropriate training and education, and have an understanding of the potential risks and correct operation methods.

12. Emergency Response: Be familiar with the laboratory's emergency response measures, including the handling of fires, leaks, and personnel injuries.

13. Mixing Avoidance: Different fluxes should not be mixed unless there is explicit experimental guidance and safety data support.

14. Stability Check: Regular checks on the stability of fluxes should be conducted and the use of expired or deteriorated products should be avoided.

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Li2B4O7,Lithium Tetraborate,Flux,12007-60-2

- Subtitle: Li2B4O7,Lithium Tetraborate,Flux,12007-60-2

- Model: R-FL-T

- 全部型号: R-FL-T-01,R-FL-T-02,R-FL-T-03,R-FL-T-04,R-FL-T-05,R-FL-T-06,R-FL-T-07,R-FL-T-08,R-FL-T-09,R-FL-T-10,R-FL-T-11,R-FL-T-12,R-FL-T-13,R-FL-T-14,R-FL-T-15,R-FL-T-16,R-FL-T-17,R-FL-T-18,12007-60-2

The RUISCI Flux is fabricated using meticulously selected high-purity raw materials and preprocessed into glass bead and crystal particle forms through an exclusive blending and synthesis technique. It exhibits uniform particles, is pollution-free, facile to use, and offers excellent application performance (requiring no calcination), thereby providing greater analytical accuracy. It can be employed for the preparation of fused glass wafers and simultaneously effectively prolongs the lifespan of platinum yellowware and fusion apparatuses. It conforms to the requirements for Flux stipulated in multiple standards such as ISO 12677 and is extensively utilized in instrumental analyses (XRF, ICP, AAS) as well as wet chemical analyses.

Flux is a type of chemical reagent capable of reducing the melting point of substances and is commonly employed to promote the melting and crystallization processes of materials at relatively low temperatures. Its primary role is to form a low-melting-point eutectic with the reactants, enhancing the fluidity of the reactants, thereby accelerating the rate of chemical reactions and elevating the purity of the reaction products. Flux usually possess excellent thermal stability and chemical inertness to avoid adverse reactions with the reactants.

The RUISCI Flux is fabricated using meticulously selected high-purity raw materials and preprocessed into glass bead and crystal particle forms through an exclusive blending and synthesis technique. It exhibits uniform particles, is pollution-free, facile to use, and offers excellent application performance (requiring no calcination), thereby providing greater analytical accuracy. It can be employed for the preparation of fused glass wafers and simultaneously effectively prolongs the lifespan of platinum yellowware and fusion apparatuses. It conforms to the requirements for Flux stipulated in multiple standards such as ISO 12677 and is extensively utilized in instrumental analyses (XRF, ICP, AAS) as well as wet chemical analyses. -

1. The relatively low melting point can effectively reduce the melting point of the reaction system, converting the solid-phase reaction into a liquid-solid two-phase reaction, thereby facilitating the dissolution of reactants and the advancement of the reaction.

2. Excellent dissolution capability enables it to dissolve the refractory components in the reactants, enhancing the reaction rate and the purity of the product.

3. Exhibiting chemical inertness at high temperatures, it does not undergo adverse reactions with the reactants to avoid the introduction of impurities.

4. Possessing low volatility to minimize losses at high temperatures and pollution to the experimental environment.

5. The particles are uniform, pollution-free, and of high purity. -

Working Environment Conditions:

1. Personal Protection: When manipulating fluxes, appropriate personal protective equipment such as laboratory safety glasses, protective gloves, and protective clothing should be worn.

2. Inhalation Avoidance: During the handling of fluxes, inhalation of their dust or fumes should be avoided. Work in a well-ventilated setting and utilize local exhaust equipment when necessary.

3. Skin Contact: In case flux accidentally comes into contact with the skin, immediate rinsing with copious amounts of water is necessary and medical assistance should be sought.

4. Eye Contact: If flux enters the eyes, immediate rinsing of the eyes with copious amounts of water for at least 15 minutes is required, and medical attention should be sought promptly.

5. Storage Conditions: Fluxes should be kept in a dry, cool, and well-ventilated location, distant from heat and fire sources.

6. Labels and Documentation: Ensure that all flux containers are distinctly labeled, indicating the contents, hazard level, and safety instructions for usage.

7. Usage Quantity: The use of fluxes should be strictly in accordance with experimental requirements and excessive usage should be avoided.

8. Waste Disposal: Waste fluxes after utilization should be dealt with in accordance with laboratory waste disposal regulations and must not be disposed of randomly.

9. Equipment Inspection: Prior to the use of fluxes, it is necessary to inspect whether all equipment intended for use with fluxes is in good condition.

10. Operating Procedures: Adhere to the laboratory's operating procedures and safety guidelines to ensure the safety of experiments.

11. Training and Education: Ensure that all personnel using fluxes have received appropriate training and education, and have an understanding of the potential risks and correct operation methods.

12. Emergency Response: Be familiar with the laboratory's emergency response measures, including the handling of fires, leaks, and personnel injuries.

13. Mixing Avoidance: Different fluxes should not be mixed unless there is explicit experimental guidance and safety data support.

14. Stability Check: Regular checks on the stability of fluxes should be conducted and the use of expired or deteriorated products should be avoided.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation