Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Fully Automatic High Pressure Pelletizing Press

Fully Automatic High Pressure Pelletizing Press

HPS

Brand:

RUISHENBAO

-

Click to select

- HPS,100T

- HPS,120T

Inventory

10

隐藏域元素占位

Overview

The HPS series is an entirely new type of automatic pelletizing press for high pressure input developed by RUISHENBAO® Analytical (Shanghai) Co., Ltd to prepare high-quality pellets, which offers the full benefits of program-controlled sample preparation for x-ray fluorescence analysis. At present, the HPS pellet press is the only and first high pressure(>60ton) press of sample preparation for XRF in market. There are two types for your requirement of which the operating pressure is individually up to 100ton and 120ton. A swing-out cross-head makes filling and cleaning of the die quick, simple and safe. A number of pressing variables can be selected, depending on the press tool employed. Precision press tools with a range of diameters and materials permit free pressing. Pelletizing parameters such as total pressing force, incremental increase and decrease of pressure as well as pressure holding time can be easily operated through a touch-screen LCD display. The pressure increase and decrease during pelletizing are controlled so that inner stresses within the sample are reduced. This allows the production of perfect pellets even with complicated sample material. The pelletizing process is controlled by the PLC program. This leads to substantial improvement in reproducibility of sample preparation and consequently more precise analysis results. The HPS pellet press is a high-quality, high pressure, precision and new engineering product with compact dimensions. It produces high-quality pressed pellets with mirrorlike surface necessary for optimal XRF results. It is ideally suited for laboratory requirements.

Features

1. Only and first high pressure pellet press for sample preparation for XRF in market with operating pressure>60 tons, two types for your requirement: 100 tons and 120 tons individually;

2. One-touch operation, easy controlling, pelletizing process is controlled directly, reliably and continuously by the PLC program;

3. Press tools with a range of diameters and materials;

4. Touch-screen LCD user interfaced; all operations and programming are through touch-screen entries;

5. A swing-out cross-head makes filling and cleaning of the die quick, simple and safe;

6. Produce high-quality pressed pellets with mirrorlike surface;

7. Best quality/price ratio in the market.

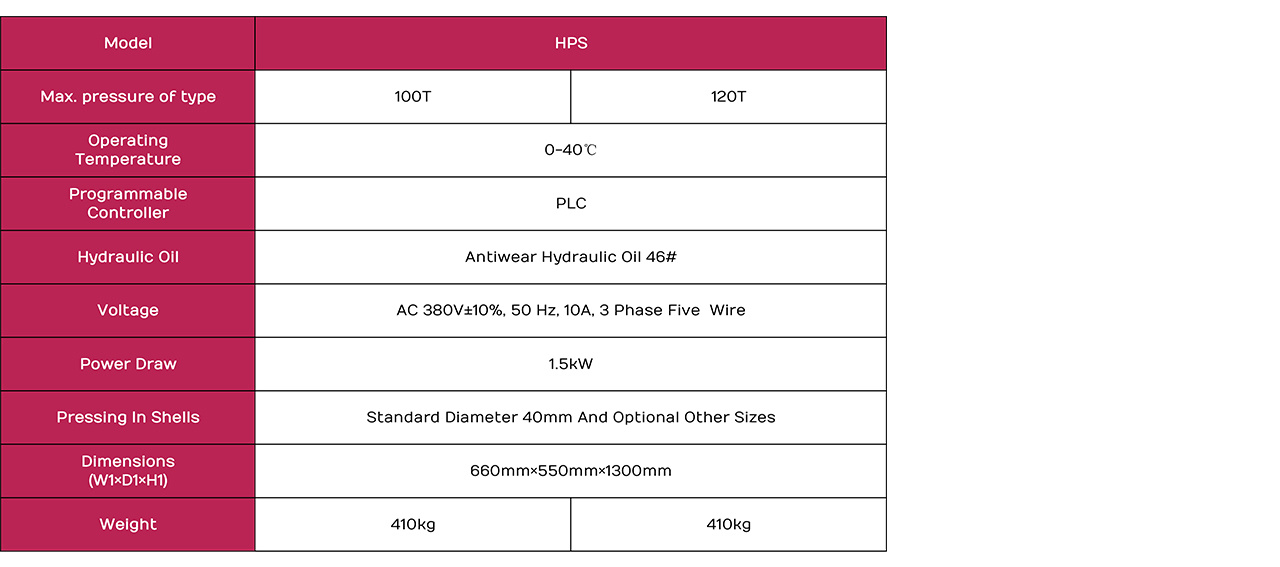

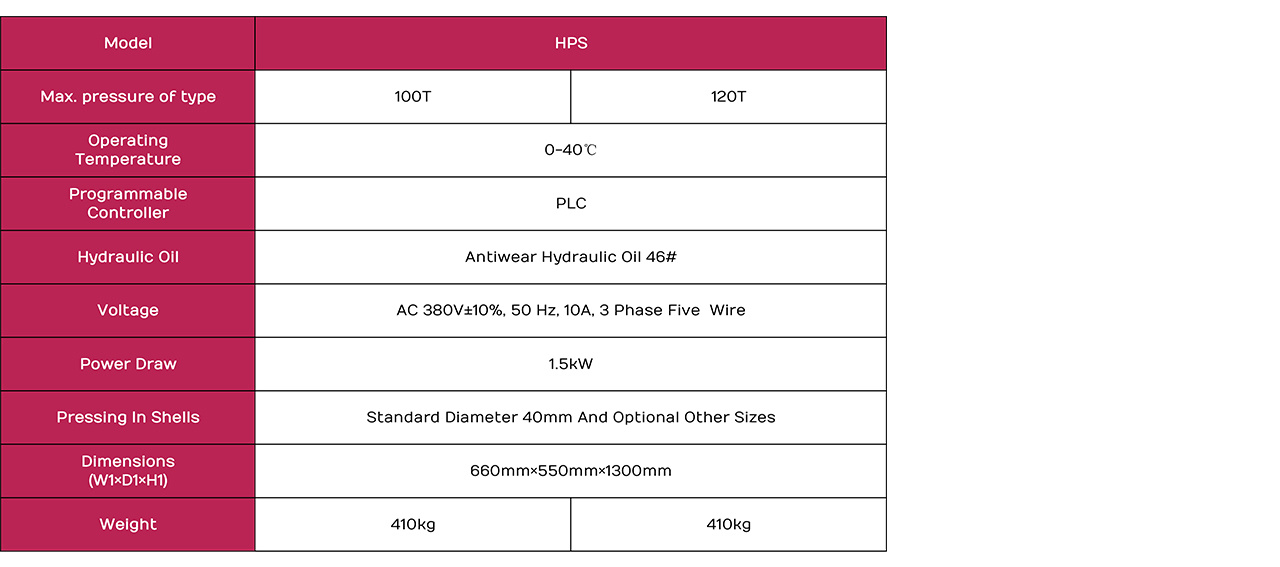

Technical data

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISHENBAO

- Commodity name: Fully Automatic High Pressure Pelletizing Press

- Subtitle: Fully Automatic High Pressure Pelletizing Press

- Model: HPS

- 全部型号: HPS

The HPS series is an entirely new type of automatic pelletizing press for high pressure input developed by RUISHENBAO® Analytical (Shanghai) Co., Ltd to prepare high-quality pellets, which offers the full benefits of program-controlled sample preparation for x-ray fluorescence analysis. At present,

The HPS series is an entirely new type of automatic pelletizing press for high pressure input developed by RUISHENBAO® Analytical (Shanghai) Co., Ltd to prepare high-quality pellets, which offers the full benefits of program-controlled sample preparation for x-ray fluorescence analysis. At present, the HPS pellet press is the only and first high pressure(>60ton) press of sample preparation for XRF in market. There are two types for your requirement of which the operating pressure is individually up to 100ton and 120ton. A swing-out cross-head makes filling and cleaning of the die quick, simple and safe. A number of pressing variables can be selected, depending on the press tool employed. Precision press tools with a range of diameters and materials permit free pressing. Pelletizing parameters such as total pressing force, incremental increase and decrease of pressure as well as pressure holding time can be easily operated through a touch-screen LCD display. The pressure increase and decrease during pelletizing are controlled so that inner stresses within the sample are reduced. This allows the production of perfect pellets even with complicated sample material. The pelletizing process is controlled by the PLC program. This leads to substantial improvement in reproducibility of sample preparation and consequently more precise analysis results. The HPS pellet press is a high-quality, high pressure, precision and new engineering product with compact dimensions. It produces high-quality pressed pellets with mirrorlike surface necessary for optimal XRF results. It is ideally suited for laboratory requirements.

-

1. Only and first high pressure pellet press for sample preparation for XRF in market with operating pressure>60 tons, two types for your requirement: 100 tons and 120 tons individually;

2. One-touch operation, easy controlling, pelletizing process is controlled directly, reliably and continuously by the PLC program;

3. Press tools with a range of diameters and materials;

4. Touch-screen LCD user interfaced; all operations and programming are through touch-screen entries;

5. A swing-out cross-head makes filling and cleaning of the die quick, simple and safe;

6. Produce high-quality pressed pellets with mirrorlike surface;

7. Best quality/price ratio in the market.

-

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation