Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

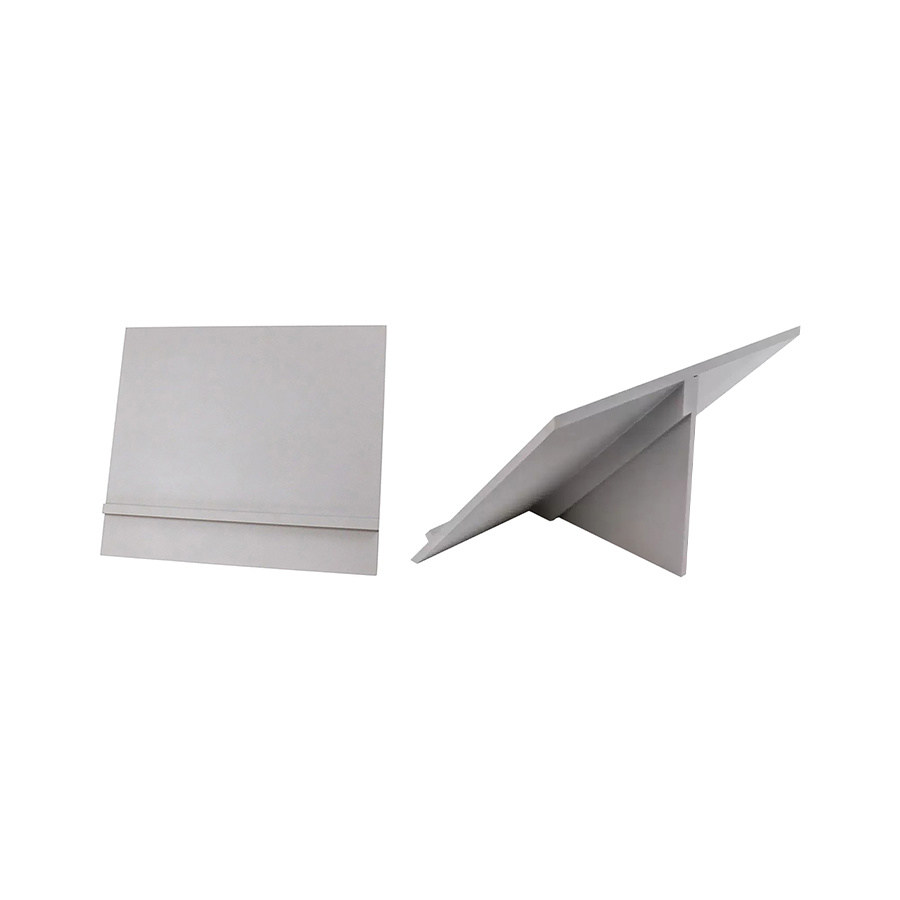

SMD(Surface Mount Device)Patch Test Clip

SMD(Surface Mount Device)Patch Test Clip

RLCR-SM

Brand:

RUISCI

-

Click to select

- RLCR-SM-A-01,≤ 1 MHz

Inventory

275

隐藏域元素占位

Overview

The SMD (Surface Mount Device) Patch Test Clip is a specialized tool for testing surface-mounted devices. It is mainly used to secure and connect SMD components during production and testing, facilitating various electrical measurements. When used with LCR testers, the probe spacing is fully compatible with mainstream testing instruments on the market.

Features

Features:

1. The SMD patch test clip adopts a tweezer-type contact heads, capable of holding extremely small-sized SMD components.

2. It can measure various electrical parameters such as resistance, capacitance, and inductance.

3. The SMD patch test clip is handheld, allowing for one-handed operation and is suitable for rapid testing.

Technical data

Precautions:

1. When clamping components, the operation should be gentle. Excessive force should be avoided to prevent damage to either the components or the test clips.

2. Ensure that the electrodes of the test clips maintain good contact with the test points of the components. However, excessive clamping force should be avoided to prevent component damage.

3. Under no circumstances should the test clips be used on live circuits. Otherwise, both the test clips and components may be damaged.

4. During the testing process, necessary anti-static measures should be implemented. For example, wear anti-static wristbands and use anti-static workbenches to prevent potential damage to SMD components caused by static electricity.

5. Maintain a clean, dust-free, and static-free testing environment to enhance the accuracy and reliability of the testing results.

6. Connect the leads of the test clips correctly to the testing instrument and ensure a secure connection.

7. After use, clean the test clips in a timely manner to remove surface stains and dust. A soft cloth can be used for wiping, while chemical solvents should be avoided.

8. Store the test clips in a dry, clean, and dust-free environment, shielding them from direct sunlight and humid conditions.

9. Do not use the test clips as regular tweezers to avoid damaging the test probes.

10. After the testing is completed, properly store the components to prevent them from being damaged or contaminated.

keyword:

SMD (Surface Mount Device) Patch Test Clip

SMD Component Tweezers

SMD Chip Component LCR Testing Tool

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: SMD(Surface Mount Device)Patch Test Clip

- Subtitle: SMD(Surface Mount Device)Patch Test Clip

- Model: RLCR-SM

- 全部型号: SMD (Surface Mount Device) Patch Test Clip,SMD Component Tweezers,SMD Chip Component LCR Testing Tool,RLCR-SM-A

The SMD (Surface Mount Device) Patch Test Clip is a specialized tool for testing surface-mounted devices. It is mainly used to secure and connect SMD components during production and testing, facilitating various electrical measurements. When used with LCR testers, the probe spacing is fully compatible with mainstream testing instruments on the market.

The SMD (Surface Mount Device) Patch Test Clip is a specialized tool for testing surface-mounted devices. It is mainly used to secure and connect SMD components during production and testing, facilitating various electrical measurements. When used with LCR testers, the probe spacing is fully compatible with mainstream testing instruments on the market.

-

Features:

1. The SMD patch test clip adopts a tweezer-type contact heads, capable of holding extremely small-sized SMD components.

2. It can measure various electrical parameters such as resistance, capacitance, and inductance.

3. The SMD patch test clip is handheld, allowing for one-handed operation and is suitable for rapid testing. -

Precautions:

1. When clamping components, the operation should be gentle. Excessive force should be avoided to prevent damage to either the components or the test clips.

2. Ensure that the electrodes of the test clips maintain good contact with the test points of the components. However, excessive clamping force should be avoided to prevent component damage.

3. Under no circumstances should the test clips be used on live circuits. Otherwise, both the test clips and components may be damaged.

4. During the testing process, necessary anti-static measures should be implemented. For example, wear anti-static wristbands and use anti-static workbenches to prevent potential damage to SMD components caused by static electricity.

5. Maintain a clean, dust-free, and static-free testing environment to enhance the accuracy and reliability of the testing results.

6. Connect the leads of the test clips correctly to the testing instrument and ensure a secure connection.

7. After use, clean the test clips in a timely manner to remove surface stains and dust. A soft cloth can be used for wiping, while chemical solvents should be avoided.

8. Store the test clips in a dry, clean, and dust-free environment, shielding them from direct sunlight and humid conditions.

9. Do not use the test clips as regular tweezers to avoid damaging the test probes.

10. After the testing is completed, properly store the components to prevent them from being damaged or contaminated.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation