Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Vibratory Disc Mill,Frequency Control

Vibratory Disc Mill,Frequency Control

RAM

Brand:

RUISCI

-

Click to select

- RAM-D,Frequency

- RAM-C,Double Speeds

- RAM-B,1400rpm

- RAM-A,960rpm

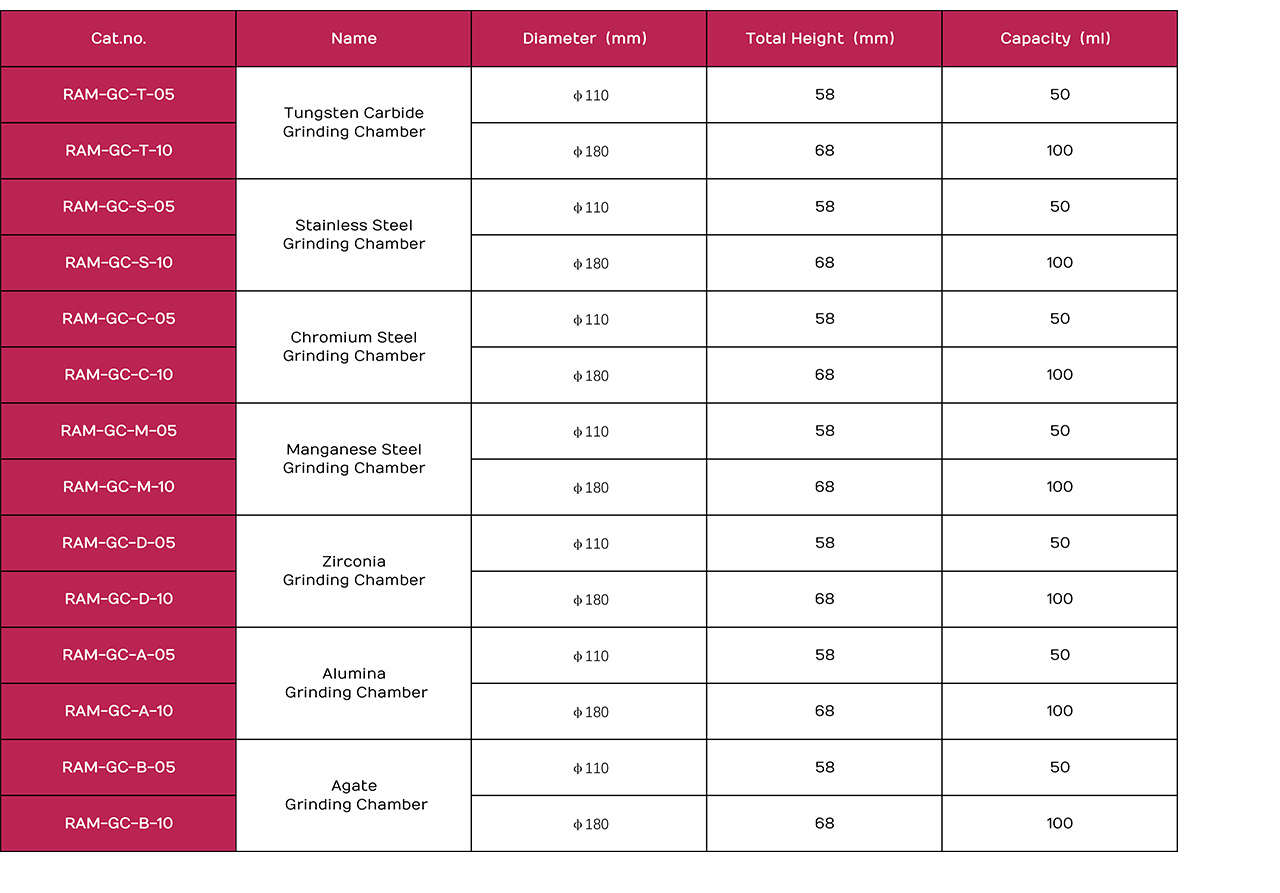

- Tungsten carbide,50mL

- Tungsten carbide,100mL

- Stainless steel,50mL

- Stainless steel,100mL

- Chromium steel,50mL

- Chromium steel,100mL

- Manganese steel ,50mL

- Manganese steel ,100mL

- Zirconia,50mL

- Zirconia,100mL

- Alumina,50mL

- Alumina,100mL

- Agate,50mL

- Agate,100mL

Inventory

2026

隐藏域元素占位

Overview

In the vibratory disc mill, the grinding is performed by horizontal circular oscillations of the grinding set on a vibrating plate. The grinding set consisting of ring and puck comminutes the grinding sample with extremely high pressure, impact forces and friction. The instrument runs steadily and smoothly, even with heavy grinding sets, at maximum speed thanks to the stabilized plane designed. It has been proven to be ideal for use in the building materials sector (cement), in geology, mineralogy, metallurgy and in power plants. Due to the high end fineness and speed RAM vibratory disc mill is the perfect mill when it comes to preparing samples for spectral analysis. The circular vibrations are produced by a frequency controlled motor or a constant speed motor according to different models. It ensures that the motor output is precisely matched to the grinding material and grinding set - which optimises the energy consumption.

Features

- Reproducible results due to stabilized plane designed;

- Extremely short grinding time;

- Vibrating plate comes equipped with spring suspension system: unique combination of vertical support, eight direction side pull and eccentric mechanism result in perfect horizontal circular oscillations of the grinding set;

- No sample loss thanks to optimum o-ring seal;

- The variety and adaptable material of grinding tools for free grinding;

- Automatic identification of grinding tool replacement without setting the parameters;

- Quick-action grinding set clamping device for convenient and safe tightening;

- Noise-insulated grinding chamber and especially safe hood locking;

- Grinding set is placed on a guide rail and easily moved to the final position.

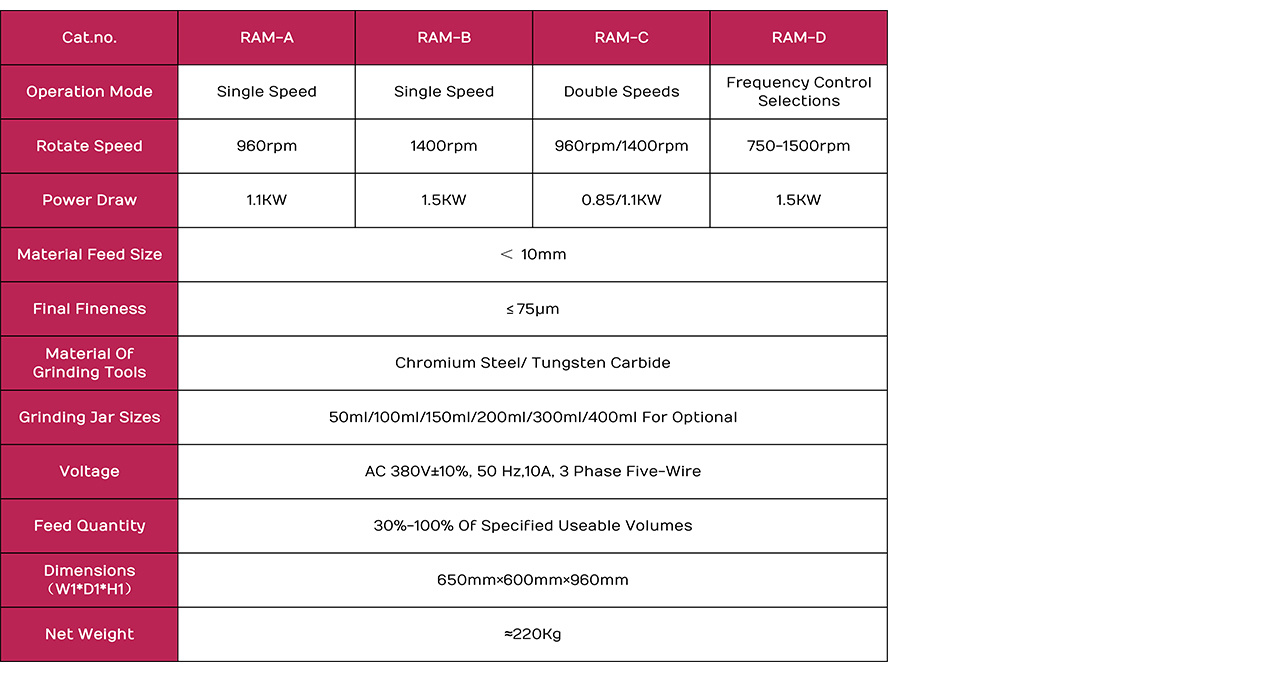

Technical data

Working environment conditions:

1. Temperature and humidity: The temperature ranges from 5℃ to 40℃, and the humidity is between 30% and 80%. Avoid extreme cold, heat or dampness.

2. Ventilation conditions: Ensure good ventilation to prevent dust accumulation. Install exhaust and filtration systems when necessary.

3. Space conditions: Provide sufficient space for equipment placement, reserve space for operation and maintenance, and keep the surroundings tidy.

4. Power supply conditions: Maintain a stable power supply that complies with the voltage and frequency requirements of the equipment. Avoid overloading or short circuits.

Precautions:

1. Safety protection: Wear glasses, gloves and earplugs, keep away from moving components, and be vigilant about dust.

2. Equipment inspection: Examine mechanical parts and power lines, select the proper grinding tools, and clean before and after usage.

3. Sample processing: The amount of sample placed should be appropriate, be cautious with dangerous materials, and ensure uniform distribution of samples.

4. Operating process: Pay attention to the equipment status during operation and do not halt the machine halfway.

5. Maintenance and upkeep: Conduct regular inspections, lubrications and cleanings, and record maintenance situations.

6. Environmental storage: Maintain a clean and dry environment. When the equipment is not in use, store it properly.

7. Emergency situations: Familiarize oneself with the machine shutdown operation and prepare emergency aid facilities.

keyword:

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Vibratory Disc Mill,Frequency Control

- Subtitle: Vibratory Disc Mill,Frequency Control

- Model: RAM

- 全部型号: RAM-A,RAM-B,RAM-C,RAM-D,RAM-GC-T-05,RAM-GC-T-10,RAM-GC-S-05,RAM-GC-S-10,RAM-GC-C-05,RAM-GC-C-10,RAM-GC-M-05,RAM-GC-M-10,RAM-GC-Z-05,RAM-GC-Z-10,RAM-GC-A-05,RAM-GC-A-10,RAM-GC-B-05,RAM-GC-B-10

The RAM vibratory disc mill series offers many practical advantages in all areas in which hard, brittle and fibrous material must be ground extremely quick down to fineness for spectral or X-ray fluorescence analysis.

In the vibratory disc mill, the grinding is performed by horizontal circular oscillations of the grinding set on a vibrating plate. The grinding set consisting of ring and puck comminutes the grinding sample with extremely high pressure, impact forces and friction. The instrument runs steadily and smoothly, even with heavy grinding sets, at maximum speed thanks to the stabilized plane designed. It has been proven to be ideal for use in the building materials sector (cement), in geology, mineralogy, metallurgy and in power plants. Due to the high end fineness and speed RAM vibratory disc mill is the perfect mill when it comes to preparing samples for spectral analysis. The circular vibrations are produced by a frequency controlled motor or a constant speed motor according to different models. It ensures that the motor output is precisely matched to the grinding material and grinding set - which optimises the energy consumption.

-

- Reproducible results due to stabilized plane designed;

- Extremely short grinding time;

- Vibrating plate comes equipped with spring suspension system: unique combination of vertical support, eight direction side pull and eccentric mechanism result in perfect horizontal circular oscillations of the grinding set;

- No sample loss thanks to optimum o-ring seal;

- The variety and adaptable material of grinding tools for free grinding;

- Automatic identification of grinding tool replacement without setting the parameters;

- Quick-action grinding set clamping device for convenient and safe tightening;

- Noise-insulated grinding chamber and especially safe hood locking;

- Grinding set is placed on a guide rail and easily moved to the final position.

-

Working environment conditions:

1. Temperature and humidity: The temperature ranges from 5℃ to 40℃, and the humidity is between 30% and 80%. Avoid extreme cold, heat or dampness.

2. Ventilation conditions: Ensure good ventilation to prevent dust accumulation. Install exhaust and filtration systems when necessary.

3. Space conditions: Provide sufficient space for equipment placement, reserve space for operation and maintenance, and keep the surroundings tidy.

4. Power supply conditions: Maintain a stable power supply that complies with the voltage and frequency requirements of the equipment. Avoid overloading or short circuits.

Precautions:

1. Safety protection: Wear glasses, gloves and earplugs, keep away from moving components, and be vigilant about dust.

2. Equipment inspection: Examine mechanical parts and power lines, select the proper grinding tools, and clean before and after usage.

3. Sample processing: The amount of sample placed should be appropriate, be cautious with dangerous materials, and ensure uniform distribution of samples.

4. Operating process: Pay attention to the equipment status during operation and do not halt the machine halfway.

5. Maintenance and upkeep: Conduct regular inspections, lubrications and cleanings, and record maintenance situations.

6. Environmental storage: Maintain a clean and dry environment. When the equipment is not in use, store it properly.

7. Emergency situations: Familiarize oneself with the machine shutdown operation and prepare emergency aid facilities.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation