Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Automatic Mortar Grinder

Mortar Grinder

RMG-A

-

Click to select

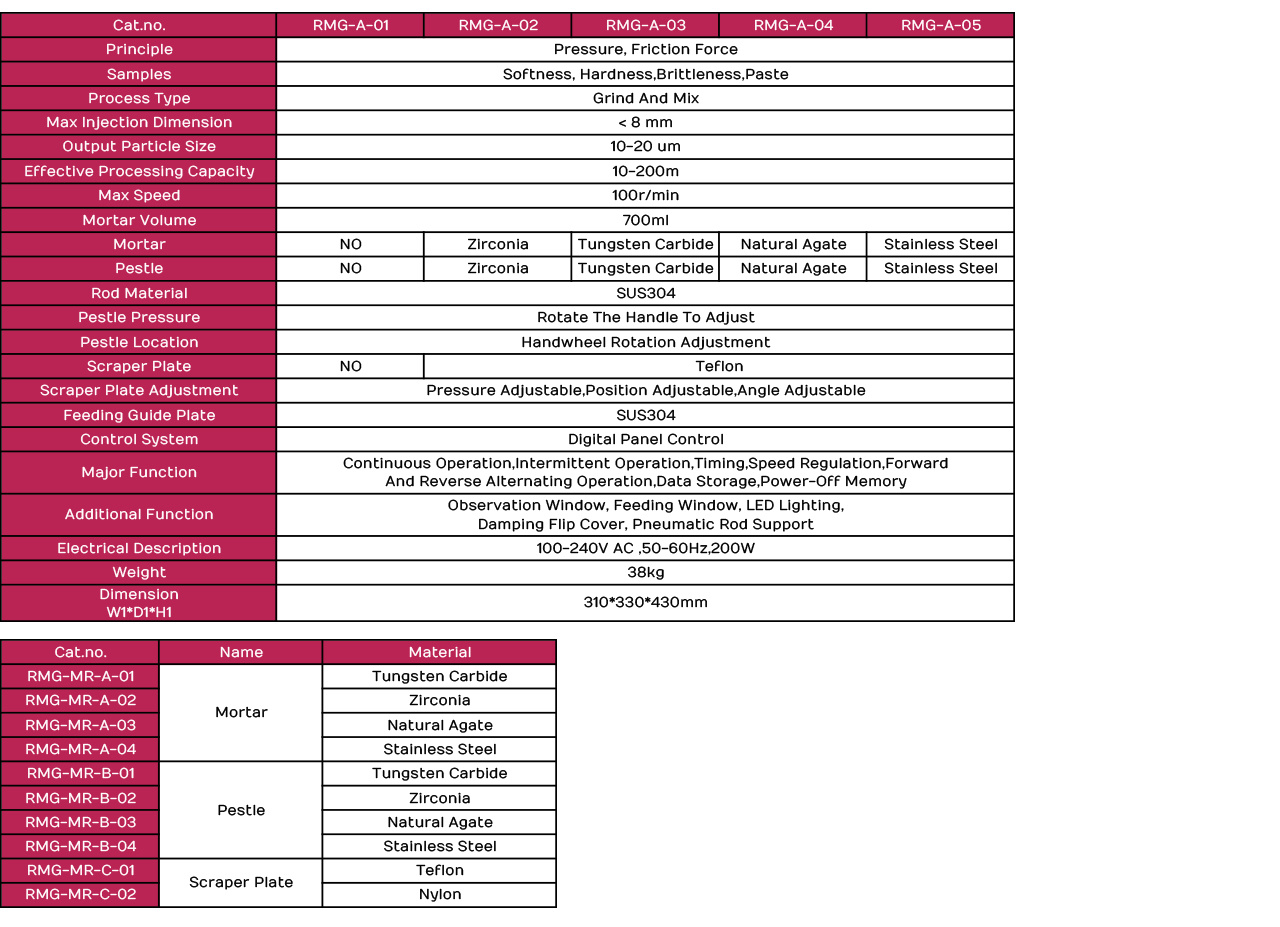

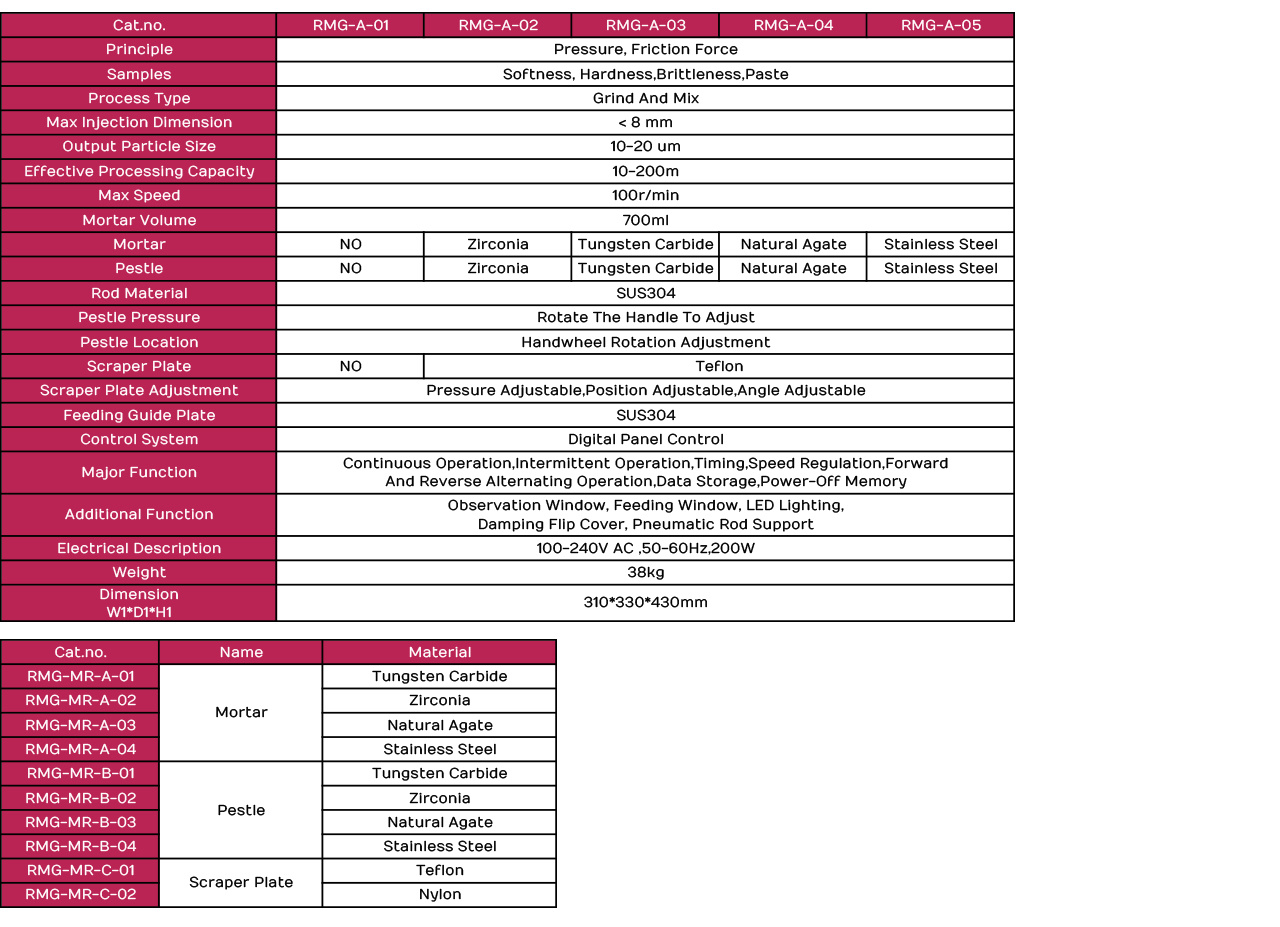

- RMG-A-01

- RMG-A-02,Zirconia

- RMG-A-03,Tungsten Carbide

- RMG-A-04,Natural Agate

- RMG-A-05,Stainless Steel

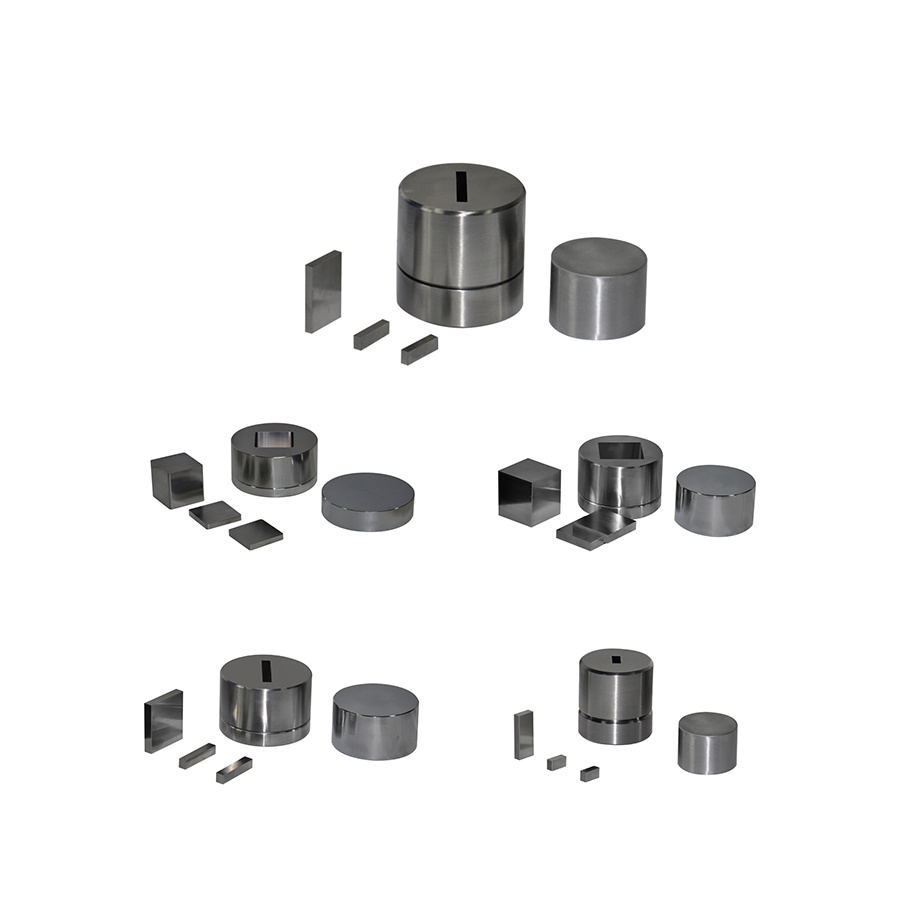

- RMG-MR-A-01,Tungsten Carbide,Mortar

- RMG-MR-A-02,Zirconia,Mortar

- RMG-MR-A-03,Natural Agate,Mortar

- RMG-MR-A-04,Stainless Steel,Mortar

- RMG-MR-B-01,Tungsten Carbide,Pestle

- RMG-MR-B-02,Zirconia,Pestle

- RMG-MR-B-03,Natural Agate,Pestle

- RMG-MR-B-04,Stainless Steel,Pestle

- RMG-MR-C-01,Teflon,Scraper

- RMG-MR-C-02,Nylon,Scraper

Inventory

2460

隐藏域元素占位

Overview

The Mortar Grinder is capable of conducting mixing and homogenization processes for powders, suspensions, pastes, and even viscous samples. The burdensome manual grinding has been substituted by more precise mechanical and electronic means, offering you a more effortless experience. Cooling or heating devices can be configured as per requirements. A wide range of grinding kits made of different materials are provided for selection, with simple and convenient replacement, and they are applicable to different samples in diverse industries.

Features

1. It restores the mild crushing and grinding by manual rolling, featuring low noise, high efficiency and fine output particle size.

2. Driven by 220V, it presents low power consumption, low loss, low failure rate, and is capable of fulfilling the demands of long-term and high-intensity experiments. It enjoys a long service life and high safety.

3. The maximum rotational speed is 100 revolutions per minute. The speed is adjustable and it can be timed. It is capable of achieving continuous grinding, intermittent grinding and alternating grinding in both forward and reverse directions.

4. A multifunctional digital panel is adopted to control and display the running time and rotational speed.

5. The flip cover is supported by a pneumatic rod. An openable feeding window and observation window are provided on the top. The grinding chamber is equipped with LED illumination.

6. The output results demonstrate strong repeatability and high consistency, guaranteeing high purity and no contamination of the samples.

7. Dry grinding, wet grinding and cryogenic grinding can be conducted, enabling the grinding of brittle, hard, soft, elastic and fibrous samples.

Technical data

Working Environment Conditions:

1. Temperature Range: 5°C - 40°C.

2. Humidity Range: 10% - 80% RH.

3. Power Supply Requirements: 100 - 240V AC, 50 - 60Hz, 200W, with proper grounding.

4. Placement Conditions: Stable, flat, dry, and well-ventilated, avoiding direct sunlight and heat sources.

Precautions:

1. Personal Protection: Wear protective glasses and gloves during operation and a mask when necessary.

2. Equipment Inspection: Inspect the power cord and grinding components for intactness before use.

3. Sample Addition: Add samples uniformly to avoid excessive or concentrated accumulation.

4. Grinding Parameters: Set the grinding time and pressure rationally based on the properties of the samples.

5. Operation Monitoring: Observe the operational status of the equipment after startup to avoid overload.

6. Cleaning: Clean the grinding components in a timely manner after grinding to prevent residues from affecting the next use.

7. Regular Inspection: Regularly check the wear of the grinding components and replace them promptly.

8. Prohibited Matters: Grinding of flammable, explosive or corrosive substances is prohibited.

keyword:

Previous:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Automatic Mortar Grinder

- Subtitle: Mortar Grinder

- Model: RMG-A

- 全部型号: RMG-A-01,RMG-A-02,RMG-A-03,RMG-A-04,RMG-A-05

The Mortar Grinder is capable of conducting mixing and homogenization processes for powders, suspensions, pastes, and even viscous samples. The burdensome manual grinding has been substituted by more precise mechanical and electronic means, offering you a more effortless experience. Cooling or heating devices can be configured as per requirements.

The Mortar Grinder is capable of conducting mixing and homogenization processes for powders, suspensions, pastes, and even viscous samples. The burdensome manual grinding has been substituted by more precise mechanical and electronic means, offering you a more effortless experience. Cooling or heating devices can be configured as per requirements. A wide range of grinding kits made of different materials are provided for selection, with simple and convenient replacement, and they are applicable to different samples in diverse industries.

-

1. It restores the mild crushing and grinding by manual rolling, featuring low noise, high efficiency and fine output particle size.

2. Driven by 220V, it presents low power consumption, low loss, low failure rate, and is capable of fulfilling the demands of long-term and high-intensity experiments. It enjoys a long service life and high safety.

3. The maximum rotational speed is 100 revolutions per minute. The speed is adjustable and it can be timed. It is capable of achieving continuous grinding, intermittent grinding and alternating grinding in both forward and reverse directions.

4. A multifunctional digital panel is adopted to control and display the running time and rotational speed.

5. The flip cover is supported by a pneumatic rod. An openable feeding window and observation window are provided on the top. The grinding chamber is equipped with LED illumination.

6. The output results demonstrate strong repeatability and high consistency, guaranteeing high purity and no contamination of the samples.

7. Dry grinding, wet grinding and cryogenic grinding can be conducted, enabling the grinding of brittle, hard, soft, elastic and fibrous samples. -

Working Environment Conditions:

1. Temperature Range: 5°C - 40°C.

2. Humidity Range: 10% - 80% RH.

3. Power Supply Requirements: 100 - 240V AC, 50 - 60Hz, 200W, with proper grounding.

4. Placement Conditions: Stable, flat, dry, and well-ventilated, avoiding direct sunlight and heat sources.Precautions:

1. Personal Protection: Wear protective glasses and gloves during operation and a mask when necessary.

2. Equipment Inspection: Inspect the power cord and grinding components for intactness before use.

3. Sample Addition: Add samples uniformly to avoid excessive or concentrated accumulation.

4. Grinding Parameters: Set the grinding time and pressure rationally based on the properties of the samples.

5. Operation Monitoring: Observe the operational status of the equipment after startup to avoid overload.

6. Cleaning: Clean the grinding components in a timely manner after grinding to prevent residues from affecting the next use.

7. Regular Inspection: Regularly check the wear of the grinding components and replace them promptly.

8. Prohibited Matters: Grinding of flammable, explosive or corrosive substances is prohibited.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation