Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Integrated Air-cooling Chiller, Lab Water Chillers

Integrated Air-cooling Chiller, Lab Water Chillers

RCW

-

Click to select

- RCW-3B,R407C,2.7kW

- RCW-5B,R407C,5.2kW

- RCW-8B,R407C,9.1kW

- RCW-12B,R407C,15kW

- RCW-3A,R410A,2.7kW

- RCW-5A,R410A,5.2kW

- RCW-8A,R410A,9.1kW

- RCW-12A,R410A,15kW

Inventory

1848

隐藏域元素占位

Overview

RCW-A series integrated air-cooling high-precision chillers are specially designed for the laboratory without installation conditions for external machines. The device employs high-efficiency flexible vortex compressors and imported electronic components and is equipped with shell tube condensers and evaporators made of copper pipes with excellent heat transferring. Except the advantages of high efficiency, easiness to clean and maintain, its compact structure improves space utilization and helps its free moving. What is more, it is apt to load or unload without the help of professional installation personnel.

Features

- Reliable stability: Most imported components are employed to ensure the stable and reliable operation;

- Fewer failures: Imported high-efficiency vortex flexible compressor with slight vibration and low failure rate;

- Excellent compatibility: Optional organic coolant, outlet temperature of freezing water as low as 5 °C;

- Fine accessories: Imported first-class accessories of the core components, with delicate structure, high efficiency and great durability.

- Easy to operate: Small-window LCD screen and control buttons with clear displays, beautiful outlook and simple operation;

- Safety: Power protection, compressor overload protection, high and low pressure protection and other multiple protection devices;;

- Smooth heat dissipation: The thread tube condenser with highly efficient heat transferring and high-end fans with hydrophilic aluminum, guaranteeing highly efficient heat transfer.

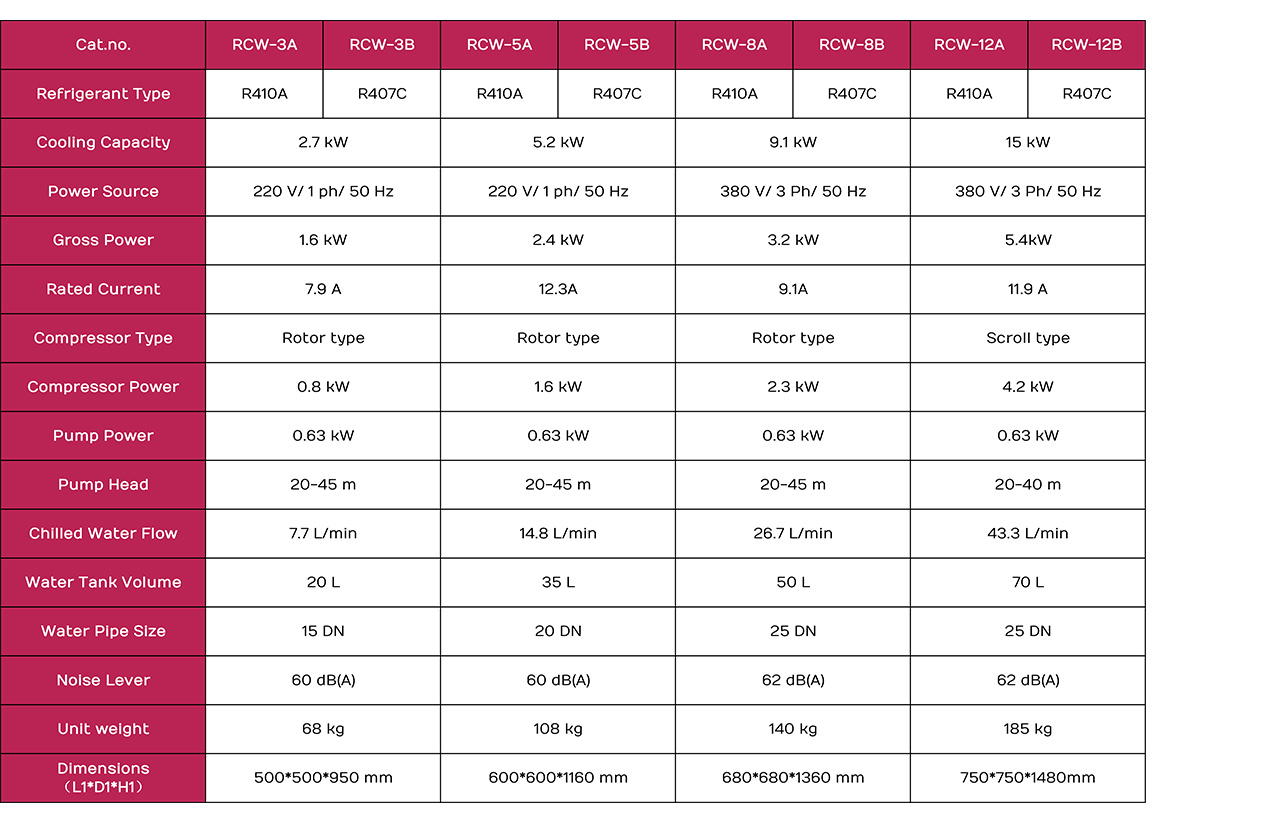

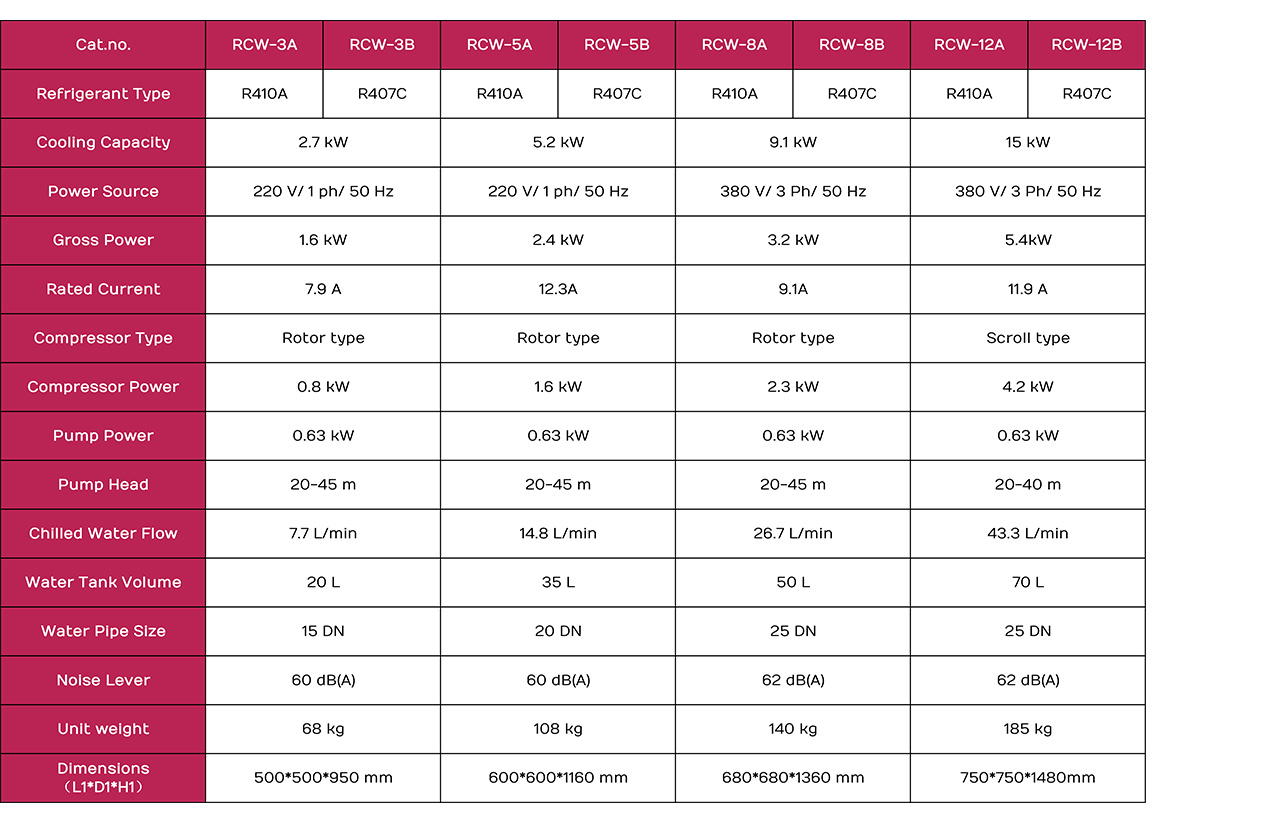

Technical data

Environmental Requirements

1. Placement Environment: The water cooler ought to be situated in an environment that is well-ventilated, clean, and dry. It should avoid direct sunlight, accumulation of dust, and humid conditions to prevent the equipment from being dampened or experiencing suboptimal heat dissipation.

2. Keep Away from Flammable and Explosive Substances: It is strictly prohibited to position flammable or explosive items in the vicinity of the equipment to prevent the occurrence of fire or explosion incidents.

3. Electrical Safety: Ensure that the equipment is well-grounded. Periodically inspect the wires and electrical components for signs of aging or loosening to prevent power failures or leakage accidents.

4. Anti-freezing Measures: When utilized in low-temperature circumstances, antifreeze should be added or the cooling water should be drained to prevent the cracking of the cooling system.

Precautions:

Ⅰ. Operating Specifications

• Training: Operators are obliged to undergo technical and safety training and obtain qualification through tests before conducting practical operations.

• Startup Sequence: Before initiating the unit, it is necessary to confirm that the unit and the controller are powered on, components such as the cooling water pump, the cooling tower fan, and others are in the activated state, and the terminal coil of the unit is also enabled. Start the main unit of the air conditioning first for normal operation.

• Shutdown Handling: In the event of equipment malfunction or the necessity for shutdown, immediate cessation of the operation should be implemented to prevent the fault from escalating or causing more severe consequences.

• Long-Term Shutdown: During long-term shutdown, the water within the unit should be evacuated, the power supply should be disconnected, and the interior of the equipment should be maintained dry.

II. Equipment Inspection and Maintenance.

1、Water Quality Management:

• Employ pure water or softened water as the cooling medium to evade the use of water containing impurities or minerals to prevent scale formation and corrosion.

• Regularly inspect the water quality of the cooling water and replace it when necessary. The replacement cycle is generally within 30 days.

2、Cooling System Inspection:

• Regularly inspect components such as the cooling water tower, condenser, evaporator, and others, clear scale and impurities, and ensure effective heat dissipation.

• Examine whether the interfaces of water pipes, valves, and others are firmly connected to prevent water leakage.

3、Pump Maintenance:

• Regularly inspect the operational status of the water pump to prevent issues such as water leakage and blockage.

• Regularly replace the lubricating oil of the water pump to maintain its optimal operational condition.

• Electrical Component Inspection: Regularly check whether the electrical components are functioning properly and replace any failed or unreliable components promptly.

III. Operation Management

• Operation Status Monitoring: During the operation of the water-cooled unit, staff members should record the operational status of the unit at regular intervals (such as every 24 hours), including parameters such as pressure and temperature, to ensure normal operation.

• Evaporator Management: Ensure that the cold water in the evaporator is in a circulating state to avoid equipment shutdown or damage resulting from overly low water temperature or low evaporation temperature and pressure.

IV. Other Notes

• Avoid Random Adjustment: It is strictly prohibited to randomly adjust the set points of control and protection elements to guarantee the stable operation of the unit.

• Parts Replacement: When replacing parts, priority should be given to using accessories provided by the brand manufacturer. Similar parts should not be randomly used as substitutes to ensure compatibility and quality.

• Maintenance Safety: During the maintenance period, a notice should be placed on the power switch indicating that maintenance is underway and power disconnection is forbidden. Maintenance should be carried out in a well-lit environment.

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Integrated Air-cooling Chiller, Lab Water Chillers

- Subtitle: Integrated Air-cooling Chiller, Lab Water Chillers

- Model: RCW

- 全部型号: RCW-3A,RCW-3B,RCW-5A,RCW-5B,RCW-8A,RCW-8B,RCW-12A,RCW-12B

RCW-A series integrated air-cooling high-precision chillers are specially designed for the laboratory without installation conditions for external machines.

RCW-A series integrated air-cooling high-precision chillers are specially designed for the laboratory without installation conditions for external machines. The device employs high-efficiency flexible vortex compressors and imported electronic components and is equipped with shell tube condensers and evaporators made of copper pipes with excellent heat transferring. Except the advantages of high efficiency, easiness to clean and maintain, its compact structure improves space utilization and helps its free moving. What is more, it is apt to load or unload without the help of professional installation personnel.

-

- Reliable stability: Most imported components are employed to ensure the stable and reliable operation;

- Fewer failures: Imported high-efficiency vortex flexible compressor with slight vibration and low failure rate;

- Excellent compatibility: Optional organic coolant, outlet temperature of freezing water as low as 5 °C;

- Fine accessories: Imported first-class accessories of the core components, with delicate structure, high efficiency and great durability.

- Easy to operate: Small-window LCD screen and control buttons with clear displays, beautiful outlook and simple operation;

- Safety: Power protection, compressor overload protection, high and low pressure protection and other multiple protection devices;;

- Smooth heat dissipation: The thread tube condenser with highly efficient heat transferring and high-end fans with hydrophilic aluminum, guaranteeing highly efficient heat transfer.

-

Environmental Requirements

1. Placement Environment: The water cooler ought to be situated in an environment that is well-ventilated, clean, and dry. It should avoid direct sunlight, accumulation of dust, and humid conditions to prevent the equipment from being dampened or experiencing suboptimal heat dissipation.

2. Keep Away from Flammable and Explosive Substances: It is strictly prohibited to position flammable or explosive items in the vicinity of the equipment to prevent the occurrence of fire or explosion incidents.

3. Electrical Safety: Ensure that the equipment is well-grounded. Periodically inspect the wires and electrical components for signs of aging or loosening to prevent power failures or leakage accidents.

4. Anti-freezing Measures: When utilized in low-temperature circumstances, antifreeze should be added or the cooling water should be drained to prevent the cracking of the cooling system.

Precautions:

Ⅰ. Operating Specifications

• Training: Operators are obliged to undergo technical and safety training and obtain qualification through tests before conducting practical operations.

• Startup Sequence: Before initiating the unit, it is necessary to confirm that the unit and the controller are powered on, components such as the cooling water pump, the cooling tower fan, and others are in the activated state, and the terminal coil of the unit is also enabled. Start the main unit of the air conditioning first for normal operation.

• Shutdown Handling: In the event of equipment malfunction or the necessity for shutdown, immediate cessation of the operation should be implemented to prevent the fault from escalating or causing more severe consequences.

• Long-Term Shutdown: During long-term shutdown, the water within the unit should be evacuated, the power supply should be disconnected, and the interior of the equipment should be maintained dry.

II. Equipment Inspection and Maintenance.

1、Water Quality Management:

• Employ pure water or softened water as the cooling medium to evade the use of water containing impurities or minerals to prevent scale formation and corrosion.

• Regularly inspect the water quality of the cooling water and replace it when necessary. The replacement cycle is generally within 30 days.

2、Cooling System Inspection:

• Regularly inspect components such as the cooling water tower, condenser, evaporator, and others, clear scale and impurities, and ensure effective heat dissipation.

• Examine whether the interfaces of water pipes, valves, and others are firmly connected to prevent water leakage.

3、Pump Maintenance:

• Regularly inspect the operational status of the water pump to prevent issues such as water leakage and blockage.

• Regularly replace the lubricating oil of the water pump to maintain its optimal operational condition.

• Electrical Component Inspection: Regularly check whether the electrical components are functioning properly and replace any failed or unreliable components promptly.

III. Operation Management

• Operation Status Monitoring: During the operation of the water-cooled unit, staff members should record the operational status of the unit at regular intervals (such as every 24 hours), including parameters such as pressure and temperature, to ensure normal operation.

• Evaporator Management: Ensure that the cold water in the evaporator is in a circulating state to avoid equipment shutdown or damage resulting from overly low water temperature or low evaporation temperature and pressure.

IV. Other Notes

• Avoid Random Adjustment: It is strictly prohibited to randomly adjust the set points of control and protection elements to guarantee the stable operation of the unit.

• Parts Replacement: When replacing parts, priority should be given to using accessories provided by the brand manufacturer. Similar parts should not be randomly used as substitutes to ensure compatibility and quality.

• Maintenance Safety: During the maintenance period, a notice should be placed on the power switch indicating that maintenance is underway and power disconnection is forbidden. Maintenance should be carried out in a well-lit environment.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation