Quality Assured

Just Buy It

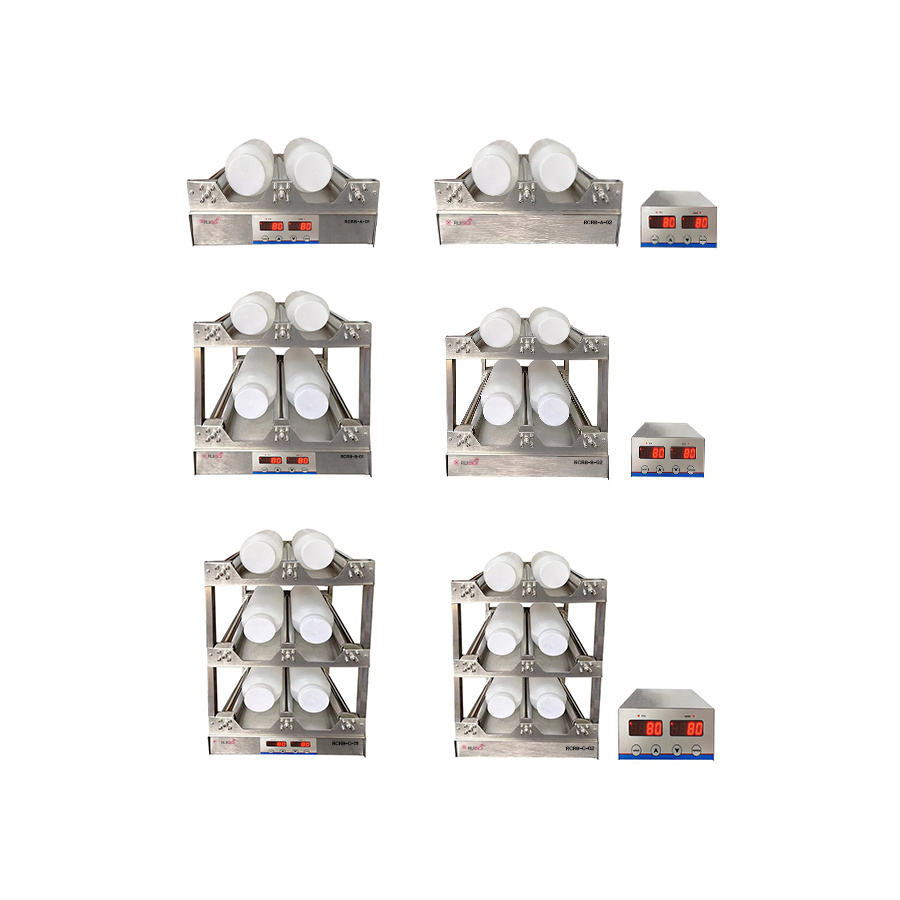

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Automatic Capping Machine

Automatic Capping Machine

RACM-A

Brand:

RUISCI

-

Click to select

- RACM-A-01

Inventory

168

隐藏域元素占位

Overview

The automatic capping machine is an automated device used for automatically tightening or loosening bottle caps. It features an aluminum alloy body, which is lighter and more environmentally friendly. It can be adapted to various bottle cap types on the market and completes the opening and closing of caps through induction triggering.

Features

1. Adjustable speed.

2. Adjustable height for tight capping.

3. Purely electric, plug and play for convenience.

4. Equipped with complete inner pads and capping heads to adapt to different bottle types.

Technical data

Precautions:

1. Pre-check before startup: Ensure the power supply and machine are functioning properly, and check if the capping head and other components are loose or damaged.

2. Working environment: Place the equipment in a dry and dust-free environment.

3. Regular maintenance: Regularly clean the equipment, replace worn parts, and calibrate the torque.

4. Bottle caps and bottles: Ensure the quality of bottle caps is up to standard, bottles are neatly arranged, and the specifications of bottle caps and bottles match.

5. Operators: Must be trained, wear protective gear, and avoid contact with moving parts.

6. Equipment safety: Avoid overloading, prevent foreign objects from entering the equipment, and strictly follow operating procedures.

7. Cleaning: Regularly clean the equipment, especially the parts in contact with medicines, using appropriate cleaning agents.

keyword:

Automatic Capping Machine

Automatic Screw Capping Machine

Automatic Induction Capping Machine

Desktop Electric Capper

Desktop Electric Screw Capper

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Automatic Capping Machine

- Subtitle: Automatic Capping Machine

- Model: RACM-A

- 全部型号: RACM-A-01,Automatic Capping Machine,Automatic Screw Capping Machine,Automatic Induction Capping Machine,Desktop Electric Capper,Desktop Electric Screw Capper

The automatic capping machine is an automated device used for automatically tightening or loosening bottle caps.

The automatic capping machine is an automated device used for automatically tightening or loosening bottle caps. It features an aluminum alloy body, which is lighter and more environmentally friendly. It can be adapted to various bottle cap types on the market and completes the opening and closing of caps through induction triggering.

-

1. Adjustable speed.

2. Adjustable height for tight capping.

3. Purely electric, plug and play for convenience.

4. Equipped with complete inner pads and capping heads to adapt to different bottle types. -

Precautions:

1. Pre-check before startup: Ensure the power supply and machine are functioning properly, and check if the capping head and other components are loose or damaged.

2. Working environment: Place the equipment in a dry and dust-free environment.

3. Regular maintenance: Regularly clean the equipment, replace worn parts, and calibrate the torque.

4. Bottle caps and bottles: Ensure the quality of bottle caps is up to standard, bottles are neatly arranged, and the specifications of bottle caps and bottles match.

5. Operators: Must be trained, wear protective gear, and avoid contact with moving parts.

6. Equipment safety: Avoid overloading, prevent foreign objects from entering the equipment, and strictly follow operating procedures.

7. Cleaning: Regularly clean the equipment, especially the parts in contact with medicines, using appropriate cleaning agents.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation