Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Centrifugal Machine

Centrifugal Machine

RCTM-A,RCTM-B,RCTM-C,RCTM-D,RCTM-E

Brand:

RUISCI

-

Click to select

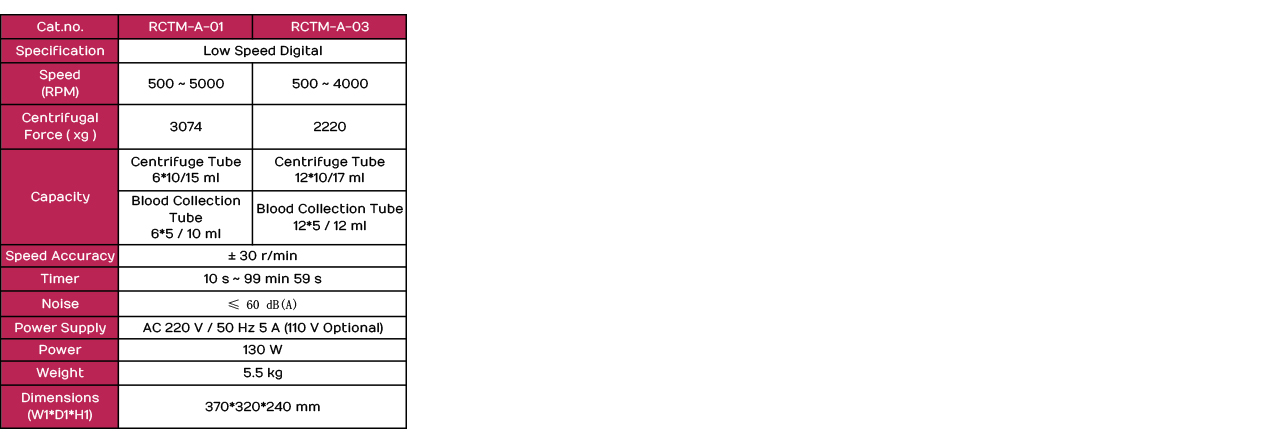

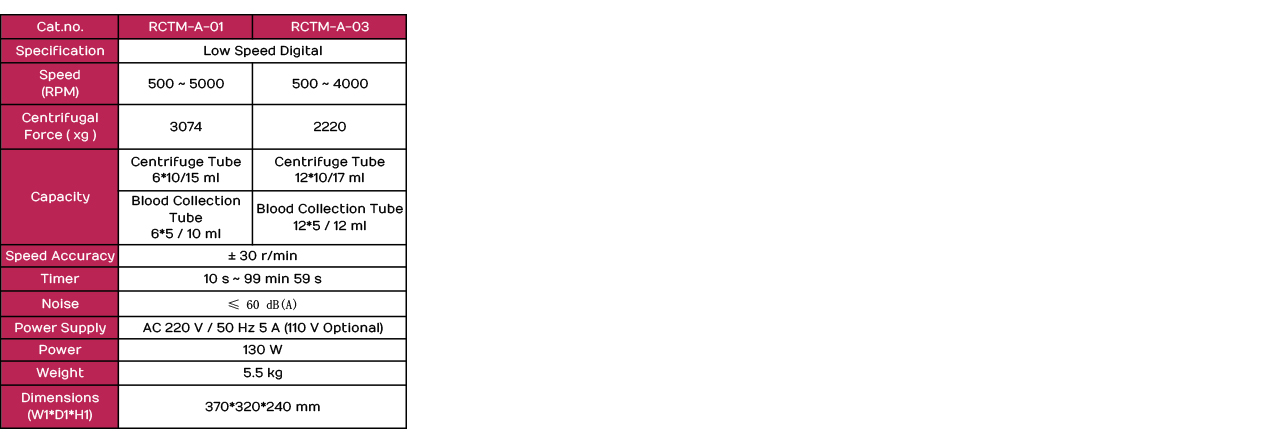

- RCTM-A-01,Low Speed Digital,3074xg,500-5000RPM

- RCTM-A-03,Low Speed Digital,2220xg,500-4000RPM

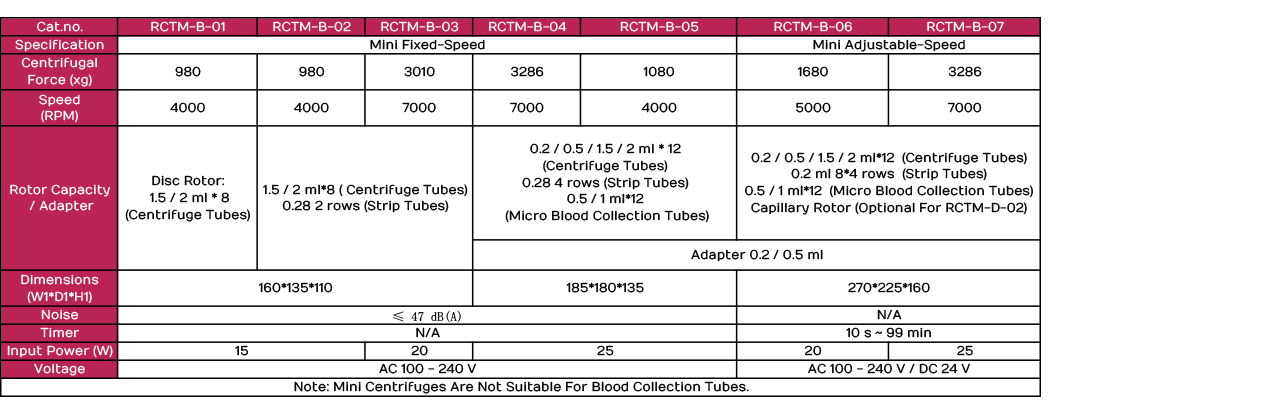

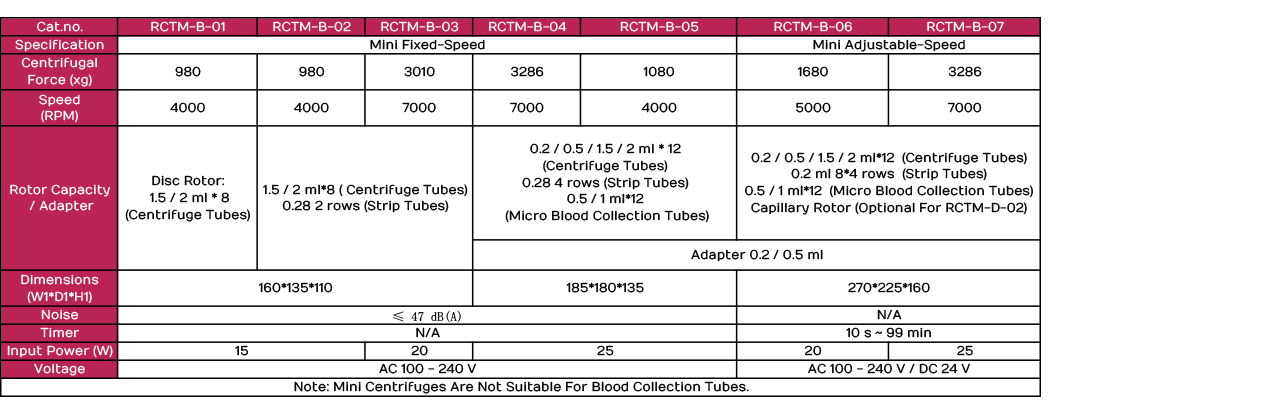

- RCTM-B-01,Mini Fixed-Speed,980xg.4000RPM

- RCTM-B-02,Mini Fixed-Speed,980xg,4000RPM

- RCTM-B-03,Mini Fixed-Speed,3010xg,7000RPM

- RCTM-B-04,Mini Fixed-Speed,3286xg,7000RPM

- RCTM-B-05,Mini Fixed-Speed,1080xg,4000RPM

- RCTM-B-06,Mini Adjustable-Speed,1680xg,5000RPM

- RCTM-B-07,Mini Adjustable-Speed,3286xg,7000RPM

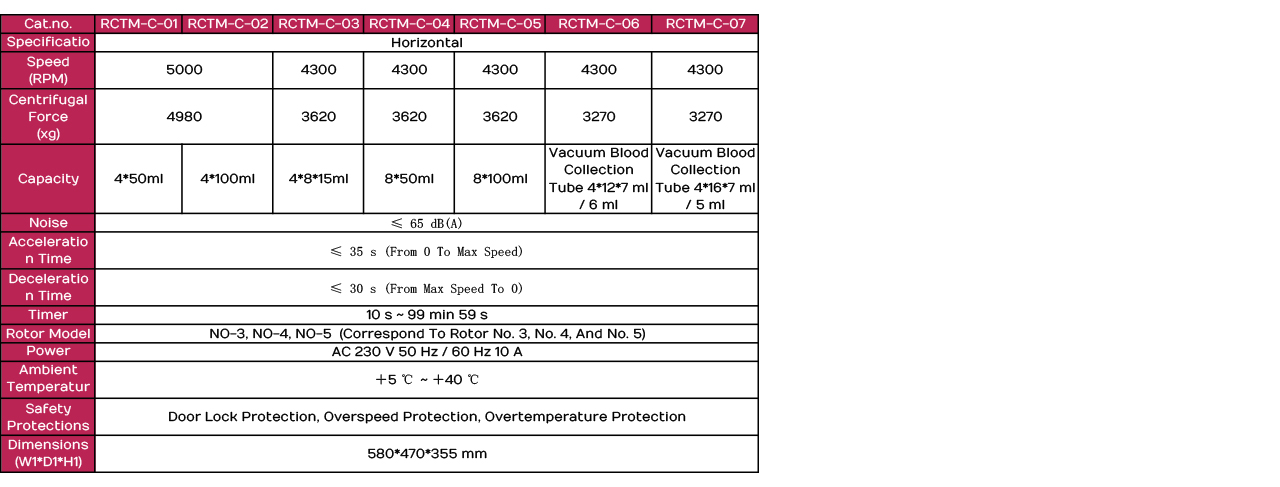

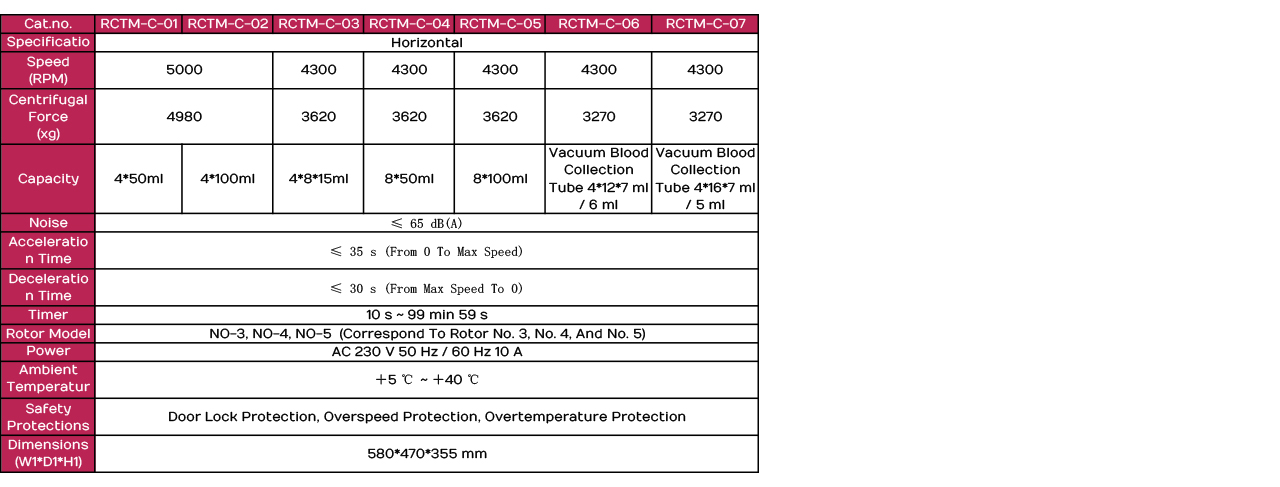

- RCTM-C-01,Horizontal Rotor Centrifuge,4980xg,5000RPM

- RCTM-C-02,Horizontal Rotor Centrifuge,4980xg,5000RPM

- RCTM-C-03,Horizontal Rotor Centrifuge,3620xg,4300RPM

- RCTM-C-04,Horizontal Rotor Centrifuge,3620xg,4300RPM

- RCTM-C-05,Horizontal Rotor Centrifuge,3620xg,4300RPM

- RCTM-C-06,Horizontal Rotor Centrifuge,3270xg,4300RPM

- RCTM-C-07,Horizontal Rotor Centrifuge,3270xg,4300RPM

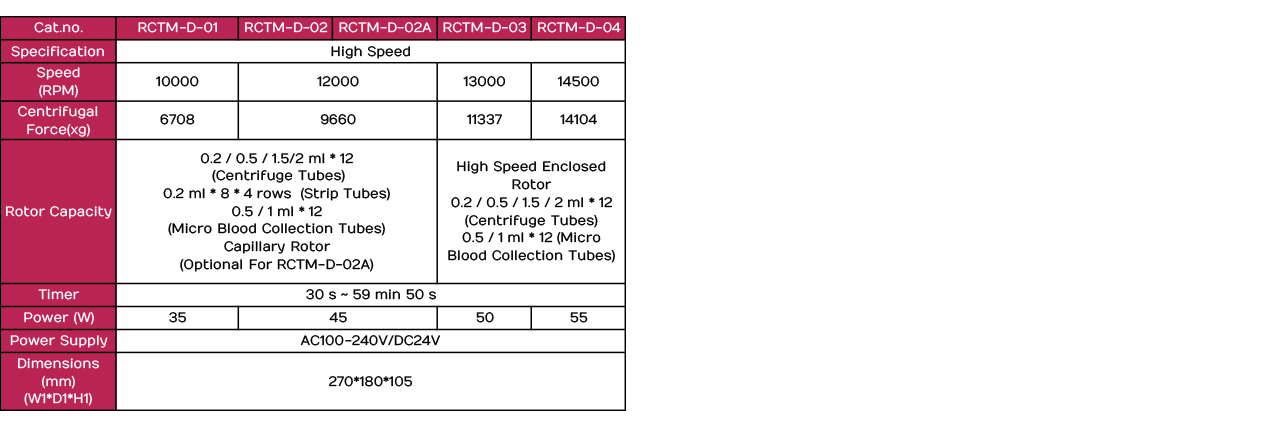

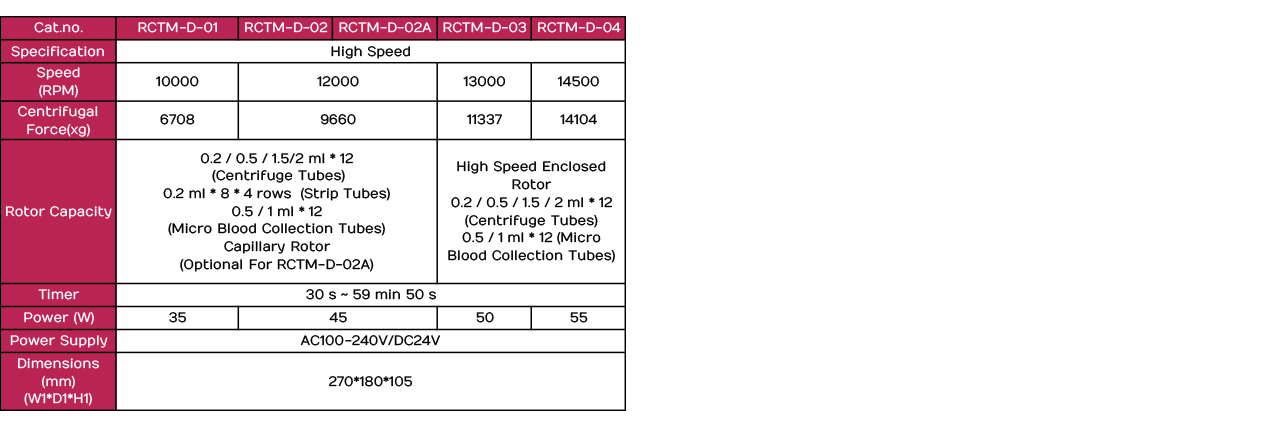

- RCTM-D-01,High Speed Centrifuge,6708xg,10000RPM

- RCTM-D-02,High Speed Centrifuge,9660xg,12000RPM

- RCTM-D-02A,High Speed Centrifuge,9660xg,12000RPM

- RCTM-D-03,High Speed Centrifuge,11337xg,13000RPM

- RCTM-D-04,High Speed Centrifuge,14104xg,14500RPM

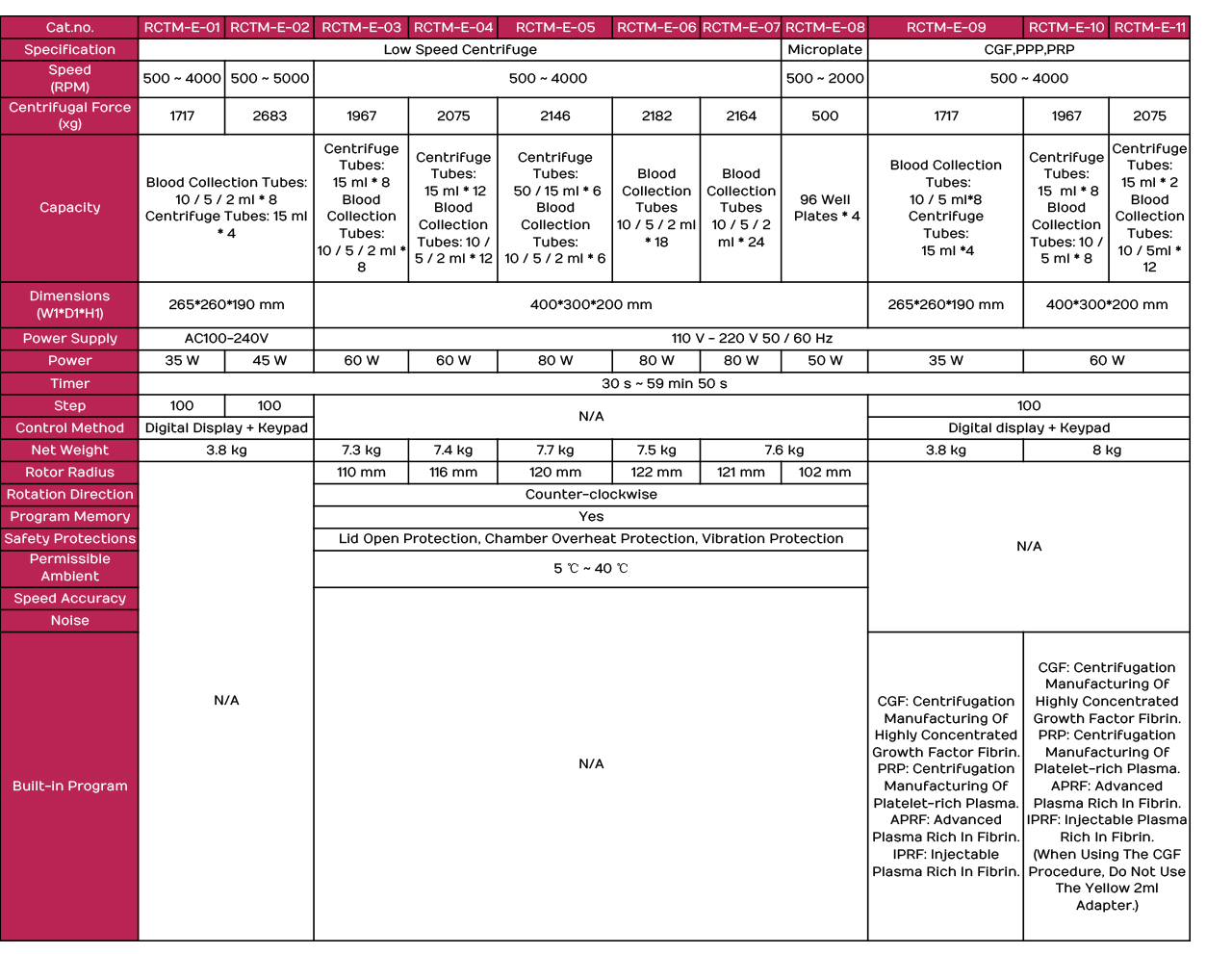

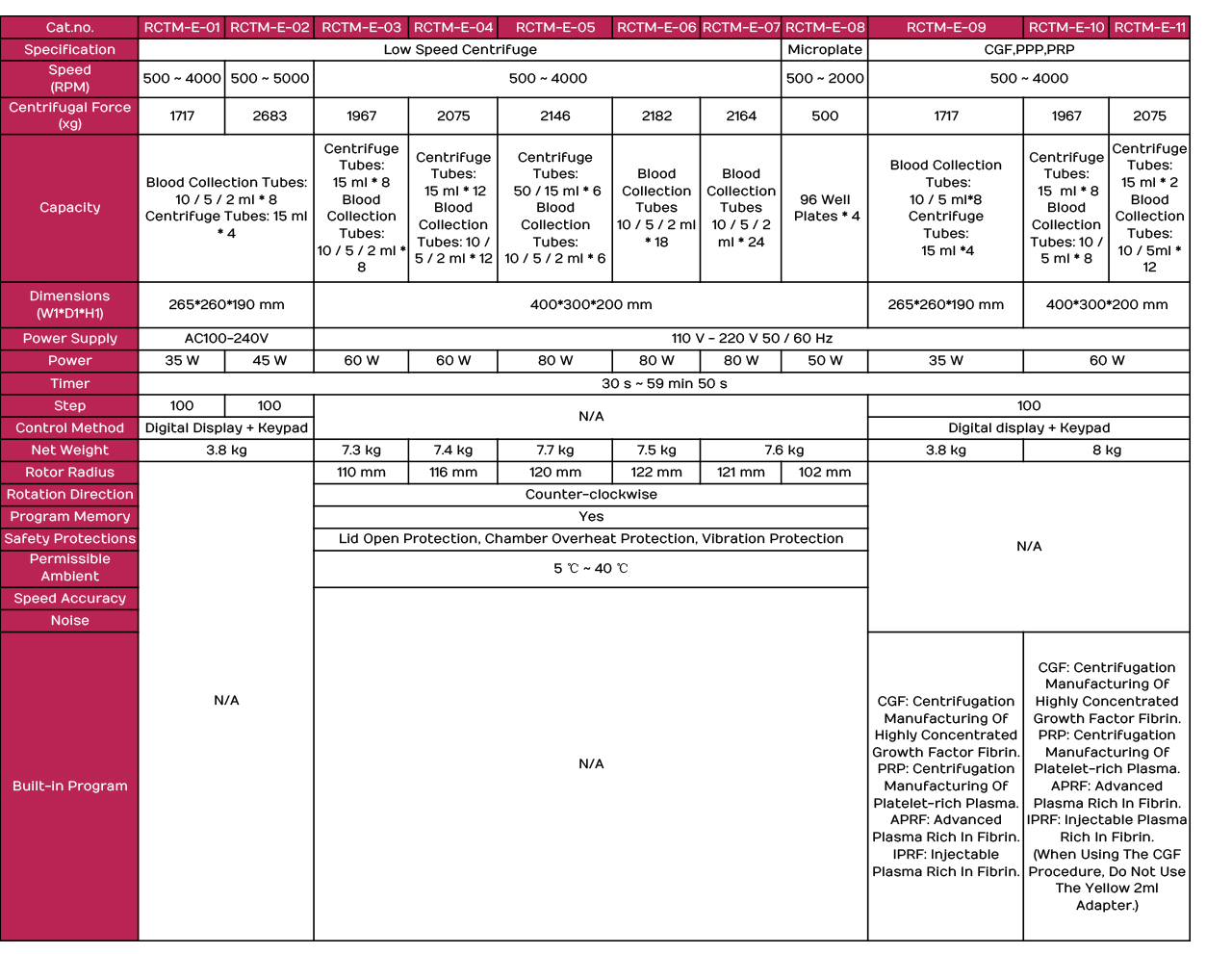

- RCTM-E-01,Low Speed Centrifuge,1717xg,500-4000RPM

- RCTM-E-02,Low Speed Centrifuge,2683xg,500-5000RPM

- RCTM-E-03,Low Speed Centrifuge,1967xg,500-4000RPM

- RCTM-E-04,Low Speed Centrifuge,2075xg,500-4000RPM

- RCTM-E-05,Low Speed Centrifuge,2146xg,500-4000RPM

- RCTM-E-06,Low Speed Centrifuge,2182xg,500-4000RPM

- RCTM-E-07,Low Speed Centrifuge,2164xg,500-4000RPM

- RCTM-E-08,Microplate,500xg,500-2000RPM

- RCTM-E-09,CGF,PPP,PRP,1717xg,500-4000RPM

- RCTM-E-10,CGF,PPP,PRP,1967xg,500-4000RPM

- RCTM-E-11,CGF,PPP,PRP,2075xg,500-4000RPM

Inventory

6816

隐藏域元素占位

Overview

Centrifuge is a laboratory instrument that uses centrifugal force to separate components of different densities in a liquid. The centrifugal force generated by high-speed rotation stratifies the components of a sample according to their density. Centrifuges are widely used in the fields of biology, chemistry, and materials science for cell separation, protein precipitation, and DNA extraction. There are various types of centrifuges depending on their rotational speed and capacity, including high-speed, low-speed, and microcentrifuges.

Features

1. Over-temperature protection: A safety temperature protection mechanism is incorporated into the design. This safeguard serves to prevent damage to samples within the chamber caused by excessive temperatures, thus enhancing the success rate of experiments.

2. Lid-opening protection: The device is equipped with a lid-opening protection feature. When the lid is opened, the operation of the centrifuge automatically halts, ensuring the safety of the experimental process.

3. Transparent lid design: The transparent lid design enables convenient experimental observation. It allows for real-time monitoring of the centrifugation process.

4. Multiple rotor specifications available: A diverse range of rotor specifications is offered to accommodate various experimental requirements.

5. Anti-slip feet: Anti-slip feet are installed on the centrifuge to ensure that the centrifuge is stable and reduces vibration during operation.

6. High-quality plastic rotors: It is not easy to be deformed even under high rotational speed to ensure the accuracy of experimental results.

7. Digital display panel: The digital display panel shows clear experimental data and the panel is easy to operate.

8. Observation window: An observation window is incorporated into the design to facilitate direct visual inspection of the experimental process and increase the intuition of operation.

9. Multifunctional Rotor: The centrifuge is furnished with a multifunctional rotor capable of processing samples of varying volumes, thereby enhancing the efficiency of experiments.

10. Program memory function: The centrifuge is equipped with a program memory function, which can save commonly used centrifugal parameters for direct use next time.

Technical data

Working environment conditions:

1. Flat ground: The centrifuge should be placed on a flat and stable ground to ensure stability and reduce vibration.

2. Avoid vibration: The centrifuge should not be placed in an environment with strong vibration, as vibration may affect the centrifugation effect and the stability of the equipment.

3. Operating space: Operators should have sufficient space for equipment operation and maintenance.

4. Dust and contamination: The working environment should be kept as clean as possible to prevent dust and contaminants from entering the equipment and affecting its performance.

5. Good ventilation: There should be sufficient space around the equipment to ensure good ventilation and prevent overheating.

6. Avoid strong electromagnetic fields: The centrifuge should be kept away from strong electromagnetic fields to avoid electromagnetic interference affecting the electronic components of the equipment.

7. Avoid direct sunlight: Direct sunlight should be avoided as strong light may affect the temperature control and electronic components of the equipment.

8. Safety protection: The working environment should comply with safety regulations, including proper grounding and emergency stop buttons.

1. Balance the samples: Ensure that the sample tubes in the centrifuge are placed evenly to avoid equipment damage or experimental failure due to imbalance.

2. Load correctly: Load samples correctly, do not overload, and do not run the centrifuge without samples.

3. Use the appropriate rotor: Select the appropriate rotor based on the type and quantity of samples, and ensure it is securely fastened.

4. Close the lid: Make sure the lid is fully closed before starting the centrifuge to prevent sample leakage or ejection.

5. Avoid overspeed: Do not exceed the maximum speed of the centrifuge or rotor to prevent equipment damage or safety accidents.

6. Monitor operation: Do not leave the centrifuge unattended during operation to handle any issues promptly.

7. Wear protective gear: Wear appropriate personal protective equipment when operating the centrifuge.

8. Dispose of waste properly: After the experiment, dispose of waste in accordance with laboratory regulations.

9. Maintenance: Regularly maintain and service the centrifuge, including cleaning, lubrication, and inspection.

10. Power off operation: Ensure the centrifuge is powered off before carrying out any maintenance or repair work.

keyword:

Low Speed Digital Centrifuge

Mini Digital Centrifuge

Horizontal Rotor Centrifuge

High Speed Centrifuge

Desktop Low Speed Centrifuge

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Centrifugal Machine

- Subtitle: Centrifugal Machine

- Model: RCTM-A,RCTM-B,RCTM-C,RCTM-D,RCTM-E

- 全部型号: RCTM-A-01,RCTM-A-03 ,RCTM-B-01,RCTM-B-02,RCTM-B-03,RCTM-B-04,RCTM-B-05,RCTM-B-06,RCTM-B-07,RCTM-C-01,RCTM-C-02,RCTM-C-03,RCTM-C-04,RCTM-C-05,RCTM-C-06,RCTM-C-07,RCTM-D-01,RCTM-D-02,RCTM-D-02A,RCTM-D-03,RCTM-D-04,RCTM-E-01,RCTM-E-02,RCTM-E-03,RCTM-E-04,RCTM-E-05,RCTM-E-06,RCTM-E-07,RCTM-E-08,RCTM-E-09,RCTM-E-10,RCTM-E-11,Low Speed Digital Centrifuge,Mini Digital Centrifuge,Horizontal Rotor Centrifuge,High Speed Centrifuge,Desktop Low Speed Centrifuge

Centrifuge is a laboratory instrument that uses centrifugal force to separate components of different densities in a liquid.

Centrifuge is a laboratory instrument that uses centrifugal force to separate components of different densities in a liquid. The centrifugal force generated by high-speed rotation stratifies the components of a sample according to their density. Centrifuges are widely used in the fields of biology, chemistry, and materials science for cell separation, protein precipitation, and DNA extraction. There are various types of centrifuges depending on their rotational speed and capacity, including high-speed, low-speed, and microcentrifuges.

-

1. Over-temperature protection: A safety temperature protection mechanism is incorporated into the design. This safeguard serves to prevent damage to samples within the chamber caused by excessive temperatures, thus enhancing the success rate of experiments.

2. Lid-opening protection: The device is equipped with a lid-opening protection feature. When the lid is opened, the operation of the centrifuge automatically halts, ensuring the safety of the experimental process.

3. Transparent lid design: The transparent lid design enables convenient experimental observation. It allows for real-time monitoring of the centrifugation process.

4. Multiple rotor specifications available: A diverse range of rotor specifications is offered to accommodate various experimental requirements.

5. Anti-slip feet: Anti-slip feet are installed on the centrifuge to ensure that the centrifuge is stable and reduces vibration during operation.

6. High-quality plastic rotors: It is not easy to be deformed even under high rotational speed to ensure the accuracy of experimental results.

7. Digital display panel: The digital display panel shows clear experimental data and the panel is easy to operate.

8. Observation window: An observation window is incorporated into the design to facilitate direct visual inspection of the experimental process and increase the intuition of operation.

9. Multifunctional Rotor: The centrifuge is furnished with a multifunctional rotor capable of processing samples of varying volumes, thereby enhancing the efficiency of experiments.

10. Program memory function: The centrifuge is equipped with a program memory function, which can save commonly used centrifugal parameters for direct use next time. -

Working environment conditions:

1. Flat ground: The centrifuge should be placed on a flat and stable ground to ensure stability and reduce vibration.

2. Avoid vibration: The centrifuge should not be placed in an environment with strong vibration, as vibration may affect the centrifugation effect and the stability of the equipment.

3. Operating space: Operators should have sufficient space for equipment operation and maintenance.

4. Dust and contamination: The working environment should be kept as clean as possible to prevent dust and contaminants from entering the equipment and affecting its performance.

5. Good ventilation: There should be sufficient space around the equipment to ensure good ventilation and prevent overheating.

6. Avoid strong electromagnetic fields: The centrifuge should be kept away from strong electromagnetic fields to avoid electromagnetic interference affecting the electronic components of the equipment.

7. Avoid direct sunlight: Direct sunlight should be avoided as strong light may affect the temperature control and electronic components of the equipment.

8. Safety protection: The working environment should comply with safety regulations, including proper grounding and emergency stop buttons.1. Balance the samples: Ensure that the sample tubes in the centrifuge are placed evenly to avoid equipment damage or experimental failure due to imbalance.

2. Load correctly: Load samples correctly, do not overload, and do not run the centrifuge without samples.

3. Use the appropriate rotor: Select the appropriate rotor based on the type and quantity of samples, and ensure it is securely fastened.

4. Close the lid: Make sure the lid is fully closed before starting the centrifuge to prevent sample leakage or ejection.

5. Avoid overspeed: Do not exceed the maximum speed of the centrifuge or rotor to prevent equipment damage or safety accidents.

6. Monitor operation: Do not leave the centrifuge unattended during operation to handle any issues promptly.

7. Wear protective gear: Wear appropriate personal protective equipment when operating the centrifuge.

8. Dispose of waste properly: After the experiment, dispose of waste in accordance with laboratory regulations.

9. Maintenance: Regularly maintain and service the centrifuge, including cleaning, lubrication, and inspection.

10. Power off operation: Ensure the centrifuge is powered off before carrying out any maintenance or repair work.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation