Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

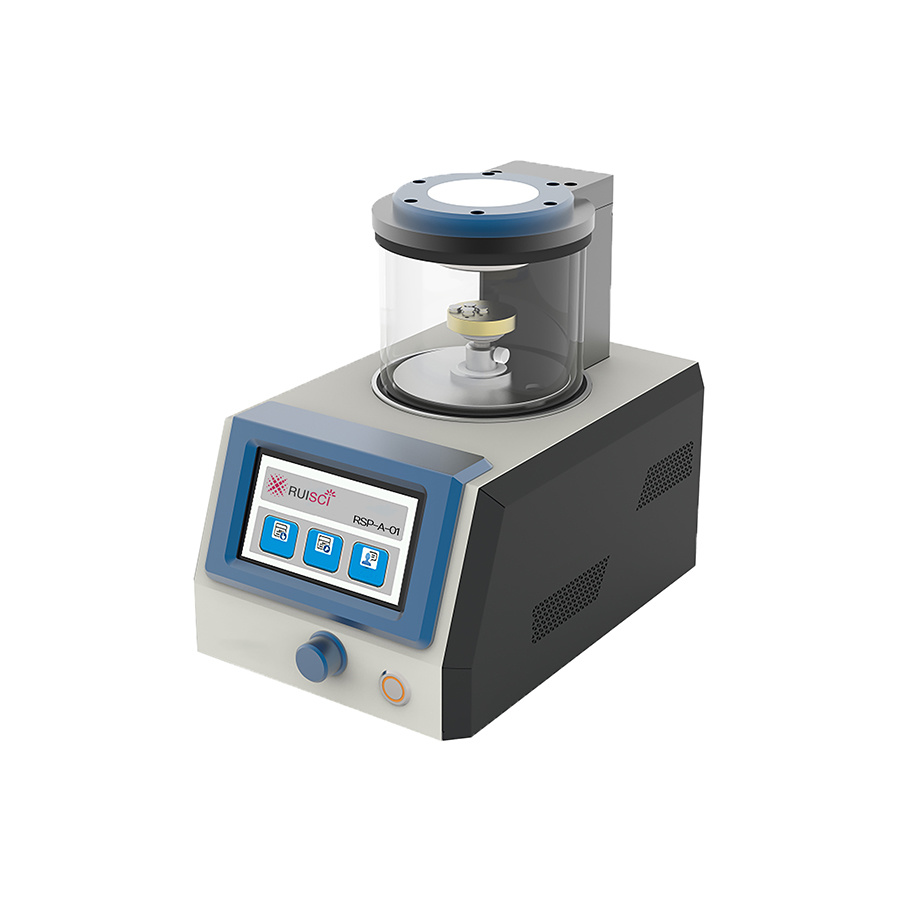

Ion Sputter Coater

Ion Sputter Coater

RSP-B,RSP-TM-B

Brand:

RUISCI

-

Click to select

- RSP-B-01,Au

- RSP-B-02,Pt

- RSP-TM-B-01

Inventory

435

隐藏域元素占位

Overview

The ion sputter coater is applicable to the high-quality coating of non-conductive samples for scanning electron microscope (SEM) imaging.

Features

1. The operation is straightforward and rapid. The sputtering current and time can be preset in advance.

2. A constant-current and cold-state precise sputtering process is achieved via a highly efficient low-voltage DC magnetron head, thereby preventing thermal damage to the sample surface.

3. The sputtering operation can be initiated with a single button click.

4. It is equipped with microprocessor control and safety interlocks.

5. Sputtering head: Low-voltage planar magnetron. The target material can be replaced rapidly, and it is equipped with a surrounding dark-zone shield.

6. The vacuum pump can be installed on an anti-vibration platform. It features a fully metallic integrated coupling system.

7. Vacuum pump: Two-stage direct-connected rotary vane vacuum pump

Technical data

1. Personal protection: Protective glasses, gloves, lab coats, etc. should be worn during operation to prevent harm to the skin and eyes.

2. High voltage safety: The ion sputtering instrument generates high voltage during operation. Do not touch the high-voltage parts during operation to avoid electric shock. Also, do not place flammable or explosive items around the equipment to prevent fire accidents.

3. Check equipment status: Before use, carefully inspect whether all components of the equipment are normal, including the vacuum pump, sputtering gun, control system, etc., to ensure the equipment is in good working condition.

4. Check power supply and gas lines: Ensure the power cord is connected correctly and undamaged, with good grounding. Also, check that the gas lines are properly connected and the gas pressure meets the requirements.

5. Sample preparation: Clean the sample surface to remove oil and impurities to prevent contamination during sputtering. Place the sample on the sample stage and secure it firmly to prevent movement during sputtering.

6. Vacuum system operation: Before evacuating, ensure all valves are closed. During the evacuation process, closely monitor the vacuum level to ensure it meets the experimental requirements. Avoid keeping the mechanical vacuum pump in the ultimate vacuum state for a long time to prevent oil backflow.

7. Target material replacement: When replacing the target material, ensure the equipment is turned off and in a safe state. Use dedicated tools for replacement and avoid direct contact with the target material to prevent scratches or contamination.

8. Equipment cleaning: After the experiment, promptly clean the vacuum chamber, sputtering head, and other components to keep the equipment clean. Regularly wipe the inside of the vacuum chamber with a cloth slightly dampened with acetone, being careful not to break the glass vacuum seal.

9. Regular maintenance: Regularly perform maintenance checks on the equipment, including cleaning, lubrication, and replacement of worn parts. The vacuum pump oil should be changed regularly, and consumable parts such as the oil mist filter should also be replaced periodically.

keyword:

SEM Coating Machine

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Ion Sputter Coater

- Subtitle: Ion Sputter Coater

- Model: RSP-B,RSP-TM-B

- 全部型号: RSP-B-01,RSP-B-02,RSP-TM-B-01,SEM Coating Machine

The ion sputter coater is applicable to the high-quality coating of non-conductive samples for scanning electron microscope (SEM) imaging.

The ion sputter coater is applicable to the high-quality coating of non-conductive samples for scanning electron microscope (SEM) imaging.

-

1. The operation is straightforward and rapid. The sputtering current and time can be preset in advance.

2. A constant-current and cold-state precise sputtering process is achieved via a highly efficient low-voltage DC magnetron head, thereby preventing thermal damage to the sample surface.

3. The sputtering operation can be initiated with a single button click.

4. It is equipped with microprocessor control and safety interlocks.

5. Sputtering head: Low-voltage planar magnetron. The target material can be replaced rapidly, and it is equipped with a surrounding dark-zone shield.

6. The vacuum pump can be installed on an anti-vibration platform. It features a fully metallic integrated coupling system.

7. Vacuum pump: Two-stage direct-connected rotary vane vacuum pump -

1. Personal protection: Protective glasses, gloves, lab coats, etc. should be worn during operation to prevent harm to the skin and eyes.

2. High voltage safety: The ion sputtering instrument generates high voltage during operation. Do not touch the high-voltage parts during operation to avoid electric shock. Also, do not place flammable or explosive items around the equipment to prevent fire accidents.

3. Check equipment status: Before use, carefully inspect whether all components of the equipment are normal, including the vacuum pump, sputtering gun, control system, etc., to ensure the equipment is in good working condition.

4. Check power supply and gas lines: Ensure the power cord is connected correctly and undamaged, with good grounding. Also, check that the gas lines are properly connected and the gas pressure meets the requirements.

5. Sample preparation: Clean the sample surface to remove oil and impurities to prevent contamination during sputtering. Place the sample on the sample stage and secure it firmly to prevent movement during sputtering.

6. Vacuum system operation: Before evacuating, ensure all valves are closed. During the evacuation process, closely monitor the vacuum level to ensure it meets the experimental requirements. Avoid keeping the mechanical vacuum pump in the ultimate vacuum state for a long time to prevent oil backflow.

7. Target material replacement: When replacing the target material, ensure the equipment is turned off and in a safe state. Use dedicated tools for replacement and avoid direct contact with the target material to prevent scratches or contamination.

8. Equipment cleaning: After the experiment, promptly clean the vacuum chamber, sputtering head, and other components to keep the equipment clean. Regularly wipe the inside of the vacuum chamber with a cloth slightly dampened with acetone, being careful not to break the glass vacuum seal.

9. Regular maintenance: Regularly perform maintenance checks on the equipment, including cleaning, lubrication, and replacement of worn parts. The vacuum pump oil should be changed regularly, and consumable parts such as the oil mist filter should also be replaced periodically.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation