Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Electric Pellet Press, Excluding Molds

Electric Pellet Press, Excluding Molds

RWP-D

-

Click to select

- RWP-20D,20T

- RWP-30D,30T

- RWP-40D,40T

- RWP-60D,60T

Inventory

172

隐藏域元素占位

Overview

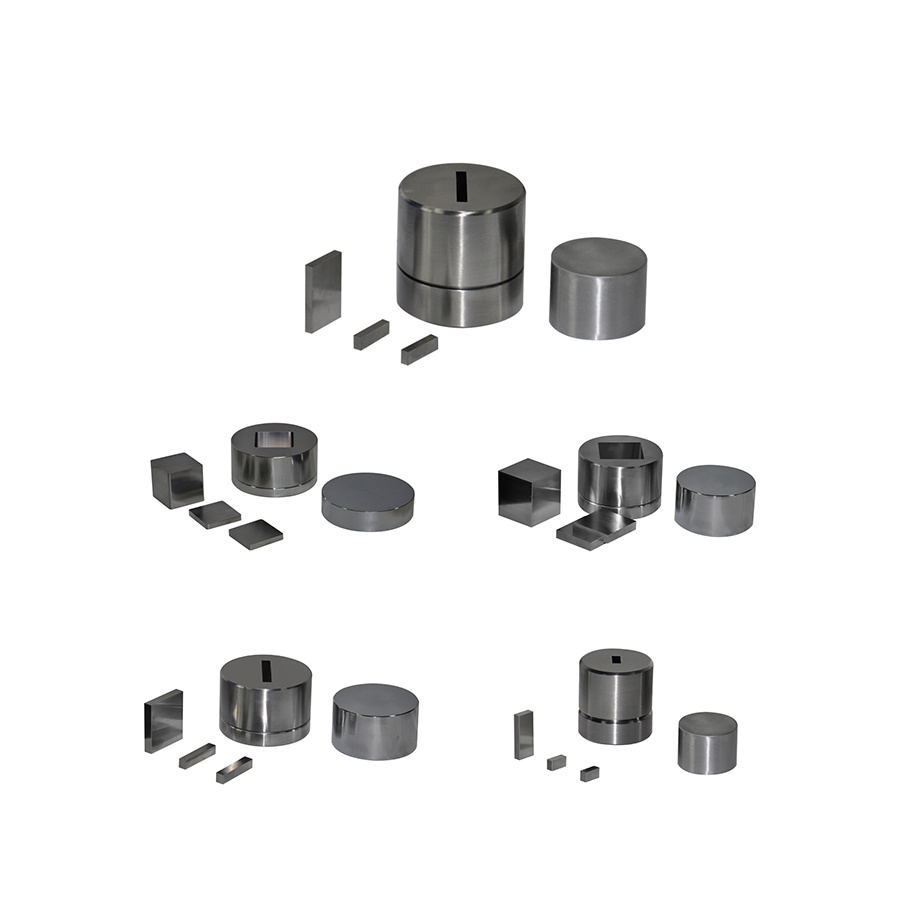

Electric Pellet Press is driven hydraulically and is primarily employed in scale sample pretreatment in laboratories, being applicable for pressing various materials. When utilized in conjunction with molds, it can compress samples of different specifications into sample tablets of regular shapes, fulfilling diverse experimental demands. Through manual operation to exert pressure, it presses powder, granular or sheet samples into regularly-shaped sample tablets, facilitating subsequent detection or analysis.

The mainframe of the pellet press adopts an integrated structure. While maintaining performance, it reduces the self-sealing connections of the product, thereby lowering the failure rate and making the replacement of accessories more straightforward and convenient. Additionally, the pressure and molds of the tablet press can be adjusted as per requirements and it is widely utilized in industries such as steel, metallurgy, chemical engineering, geology, cement, ceramic refractory materials, etc. It is a commonly employed sample preparation tool in laboratories.Electric Pellet Press is particularly suitable for the preparation of high-quality samples for spectral analysis, such as X-ray fluorescence analysis [XRF], infrared spectroscopy [IR]

Features

1. High efficiency production: Electric pellet presses, driven by electric motors, can achieve rapid and continuous tablet pressing processes, significantly enhancing production efficiency and meeting the demands of large-scale production.

2. High precision control: Utilizing motor control for pressure and speed ensures a more stable and precise tablet pressing process, guaranteeing consistency in tablet shape, size, and hardness, and improving product quality.

3. Easy operation: Electric tablet presses are typically equipped with touch screens or button-based operation interfaces, making them simple and intuitive to operate, thereby reducing the training costs and time for operators.

4. Flexible adjustment: Equipped with a simple adjustment system, parameters such as pressing thickness and filling depth can be conveniently adjusted to meet various production requirements.

5. High safety: Safety performance is emphasized during design and manufacturing. Operators do not need to directly contact the tablet molds, reducing safety risks.

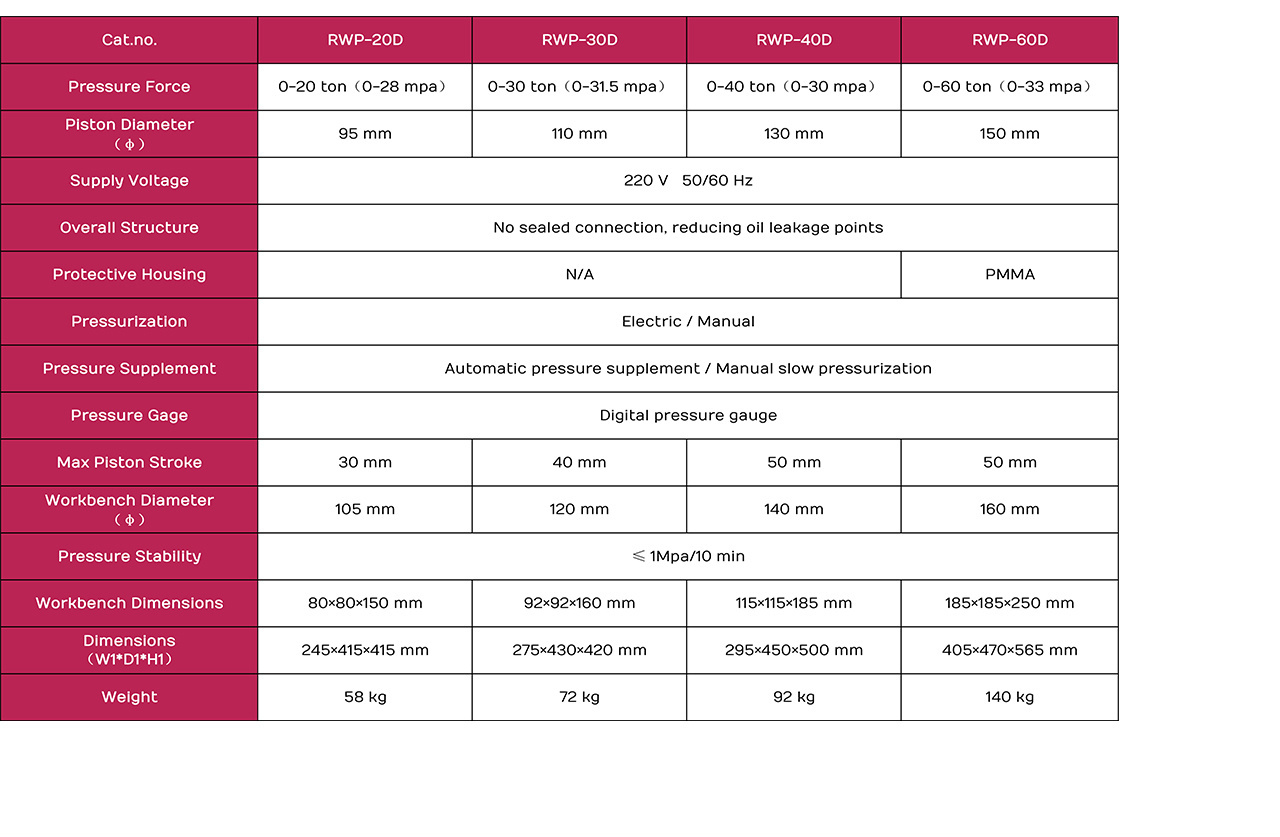

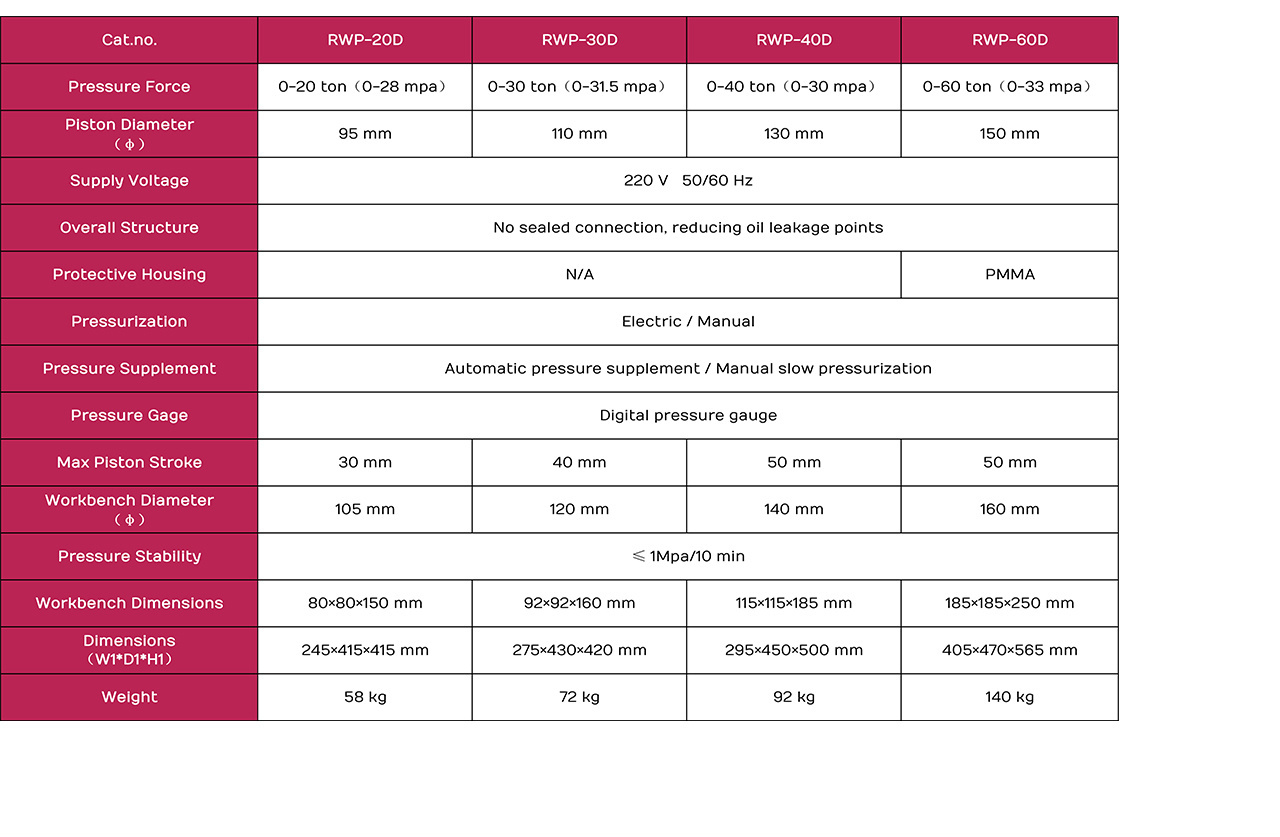

Technical data

Environmental Requirements:

1. Suitable Temperature and Humidity: The tablet press is optimally utilized in an environment with a temperature ranging from 18°C to 25°C and a humidity controlled at approximately 45% to 65% to avert the adhesion of samples due to insufficient dryness.

2. Cleanliness of the Working Area: Ensure that the working area of the tablet press is immaculate and free of any extraneous matter.

3. Inspection of the Power Cord: Examine whether the power cord and plug of the tablet press are intact.

4. Stable Placement: The tablet press ought to be positioned on a stable platform, distant from vibration sources, shielded from direct sunlight and heat radiation, and placed in a dry locale to evade the influence of moisture and air currents.

Precautions:

1. Preparations Prior to Operation: Operators are mandatorily required to undergo relevant training and be conversant with the working principle, operational procedures, and precautions of the tablet press.

2. Donning Protective Gear: Prior to operation, operators should don personal protective equipment such as work clothes, safety helmets, protective glasses, earplugs, protective gloves, and anti-slip shoes.

3. Correct Operation: Conduct operations in accordance with the operation manual and work processes. Any random alteration or skipping of steps is strictly prohibited.

4. Maintenance of a Safe Distance: During the operation process, operators should sustain a certain safe distance to ensure prompt evasion in the event of an emergency.

5. Equipment Maintenance: During operation, pay meticulous attention to the operational status of the equipment. In the event of any anomaly being detected, immediate cessation of operation is imperative and notification to relevant personnel for maintenance or overhaul is necessary.

6. Stopping the Equipment: Upon conclusion of the operation, promptly halt the operation of the equipment and undertake corresponding cleaning and maintenance tasks.

7. Site Cleanup: Clear the working area to maintain tidiness and dryness, thereby preventing accidents such as falls and slips.

8.Regular Inspections: Periodically inspect the cooling system of the tablet press, encompassing the oil cylinder and mold, to ensure normal functionality.

9.Avoidance of Overloading: Under no circumstances should the maximum processing capacity stipulated for the equipment be exceeded to prevent equipment damage or the occurrence of accidents.

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Electric Pellet Press, Excluding Molds

- Subtitle: Electric Pellet Press, Excluding Molds

- Model: RWP-D

- 全部型号: RWP-20D,RWP-30D,RWP-40D,RWP-60D,

Electric Pellet Press is driven hydraulically and is primarily employed in scale sample pretreatment in laboratories, being applicable for pressing various materials. When utilized in conjunction with molds, it can compress samples of different specifications into sample tablets of regular shapes, fulfilling diverse experimental demands. Through manual operation to exert pressure, it presses powder, granular or sheet samples into regularly-shaped sample tablets, facilitating subsequent detection or analysis.

Electric Pellet Press is driven hydraulically and is primarily employed in scale sample pretreatment in laboratories, being applicable for pressing various materials. When utilized in conjunction with molds, it can compress samples of different specifications into sample tablets of regular shapes, fulfilling diverse experimental demands. Through manual operation to exert pressure, it presses powder, granular or sheet samples into regularly-shaped sample tablets, facilitating subsequent detection or analysis.

The mainframe of the pellet press adopts an integrated structure. While maintaining performance, it reduces the self-sealing connections of the product, thereby lowering the failure rate and making the replacement of accessories more straightforward and convenient. Additionally, the pressure and molds of the tablet press can be adjusted as per requirements and it is widely utilized in industries such as steel, metallurgy, chemical engineering, geology, cement, ceramic refractory materials, etc. It is a commonly employed sample preparation tool in laboratories.Electric Pellet Press is particularly suitable for the preparation of high-quality samples for spectral analysis, such as X-ray fluorescence analysis [XRF], infrared spectroscopy [IR] -

1. High efficiency production: Electric pellet presses, driven by electric motors, can achieve rapid and continuous tablet pressing processes, significantly enhancing production efficiency and meeting the demands of large-scale production.

2. High precision control: Utilizing motor control for pressure and speed ensures a more stable and precise tablet pressing process, guaranteeing consistency in tablet shape, size, and hardness, and improving product quality.

3. Easy operation: Electric tablet presses are typically equipped with touch screens or button-based operation interfaces, making them simple and intuitive to operate, thereby reducing the training costs and time for operators.

4. Flexible adjustment: Equipped with a simple adjustment system, parameters such as pressing thickness and filling depth can be conveniently adjusted to meet various production requirements.

5. High safety: Safety performance is emphasized during design and manufacturing. Operators do not need to directly contact the tablet molds, reducing safety risks. -

Environmental Requirements:

1. Suitable Temperature and Humidity: The tablet press is optimally utilized in an environment with a temperature ranging from 18°C to 25°C and a humidity controlled at approximately 45% to 65% to avert the adhesion of samples due to insufficient dryness.

2. Cleanliness of the Working Area: Ensure that the working area of the tablet press is immaculate and free of any extraneous matter.

3. Inspection of the Power Cord: Examine whether the power cord and plug of the tablet press are intact.

4. Stable Placement: The tablet press ought to be positioned on a stable platform, distant from vibration sources, shielded from direct sunlight and heat radiation, and placed in a dry locale to evade the influence of moisture and air currents.

Precautions:

1. Preparations Prior to Operation: Operators are mandatorily required to undergo relevant training and be conversant with the working principle, operational procedures, and precautions of the tablet press.

2. Donning Protective Gear: Prior to operation, operators should don personal protective equipment such as work clothes, safety helmets, protective glasses, earplugs, protective gloves, and anti-slip shoes.

3. Correct Operation: Conduct operations in accordance with the operation manual and work processes. Any random alteration or skipping of steps is strictly prohibited.

4. Maintenance of a Safe Distance: During the operation process, operators should sustain a certain safe distance to ensure prompt evasion in the event of an emergency.

5. Equipment Maintenance: During operation, pay meticulous attention to the operational status of the equipment. In the event of any anomaly being detected, immediate cessation of operation is imperative and notification to relevant personnel for maintenance or overhaul is necessary.

6. Stopping the Equipment: Upon conclusion of the operation, promptly halt the operation of the equipment and undertake corresponding cleaning and maintenance tasks.

7. Site Cleanup: Clear the working area to maintain tidiness and dryness, thereby preventing accidents such as falls and slips.

8.Regular Inspections: Periodically inspect the cooling system of the tablet press, encompassing the oil cylinder and mold, to ensure normal functionality.

9.Avoidance of Overloading: Under no circumstances should the maximum processing capacity stipulated for the equipment be exceeded to prevent equipment damage or the occurrence of accidents.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation