Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Detachable Mold,Applicable to RUISCI Pellet Press

Detachable Mold,Applicable to RUISCI Pellet Press

CM-S

-

Click to select

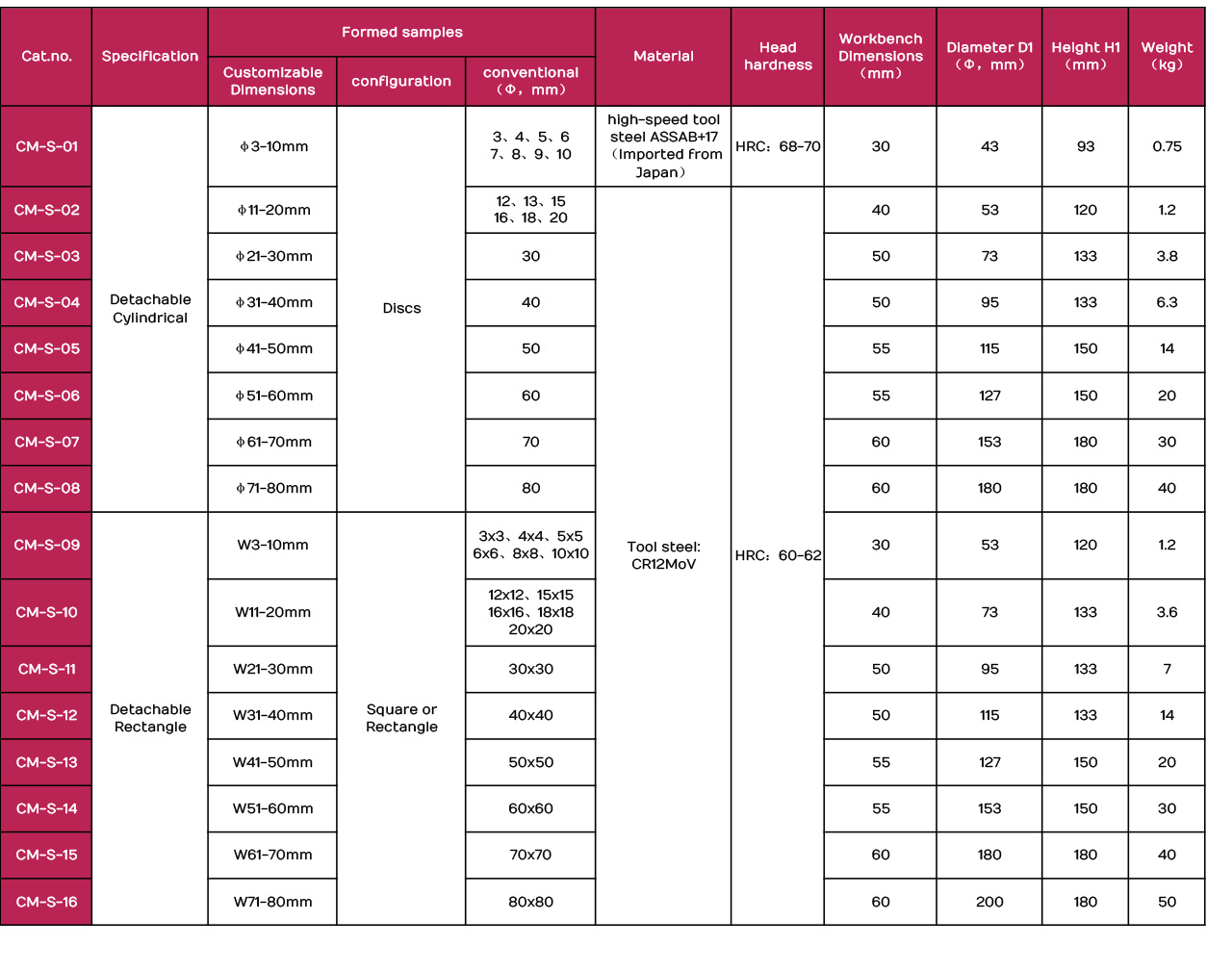

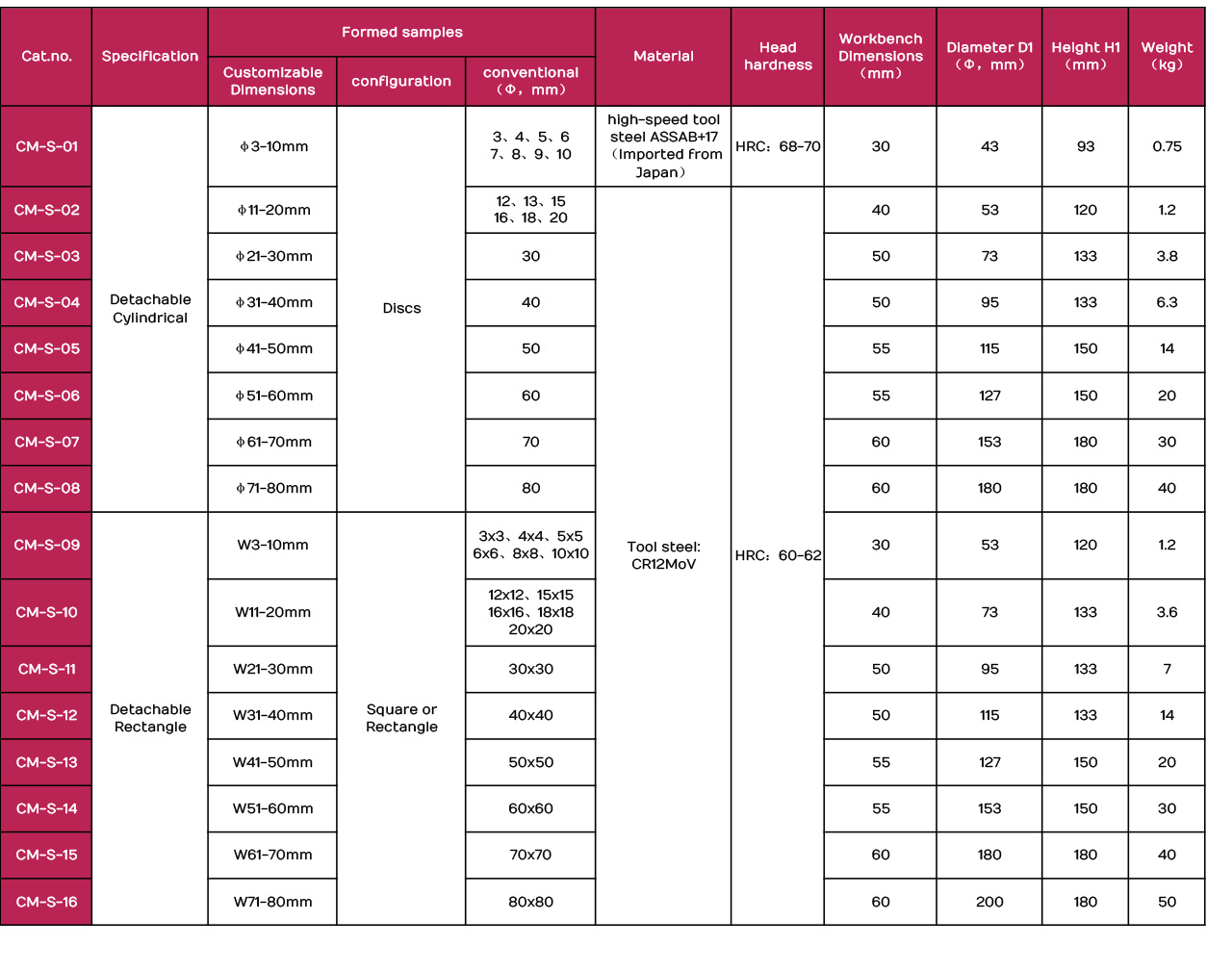

- CM-S-01,φ3-10mm

- CM-S-02,φ11-20mm

- CM-S-03,φ21-30mm

- CM-S-04,φ31-40mm

- CM-S-05,φ41-50mm

- CM-S-06,φ51-60mm

- CM-S-07,φ61-70mm

- CM-S-08,φ71-80mm

- CM-S-09,W3-10mm

- CM-S-10,W11-20mm

- CM-S-11,W21-30mm

- CM-S-12,W31-40mm

- CM-S-13,W41-50mm

- CM-S-14,W51-60mm

- CM-S-15,W61-70mm

- CM-S-16,W81-80mm

Inventory

1968

隐藏域元素占位

Overview

Detachable Mold is a specific type of laboratory mold that is usually utilized in pellet presses for the production of sample pieces of particular shapes. The structure of this mold is composed of several components and can be disassembled conveniently, facilitating the demolding of the finished sample pieces. In the pelletizing process, after the material is filled into the mold cavity, pressure is exerted to shape the material into sample pieces. Once the shaping is accomplished and the mold is disassembled, the sample pieces can be extracted smoothly. This mold is applicable for the preparation of sample bottles with complex shapes and high demands for demolding, effectively enhancing the efficiency of preparation and the quality of sample pieces. This mold is specifically dedicated for RUISCI Pellet Press.

Features

1. Facilitated Demolding: The detachable mold enables the formed sample pieces to be extracted effortlessly, minimizing the phenomenon of mold adhesion and enhancing production efficiency.

2. High Applicability: It is capable of manufacturing complex and unconventional-shaped sample pieces, satisfying diverse product requirements, such as polygonal ones, those with grooves or raised patterns, etc.

3. High Precision: The components are closely coordinated, guaranteeing the dimensional accuracy and shape consistency of the sample pieces and ensuring product quality.

4. Excellent Durability: Commonly fabricated from premium steel and other materials, and subjected to precise processing and heat treatment, it exhibits high strength and wear resistance, featuring a long service life.

5. Convenient Maintenance: The combined structure is relatively straightforward, facilitating disassembly and cleaning, and incurring relatively low daily maintenance costs.

Technical data

Precautions:

1. Mold cleaning: The mold should be thoroughly cleaned before and after use to prevent cross-contamination and prolong its service life.

2. Mold condition inspection: Regularly check the mold for wear, cracks, or other damages to ensure its good condition.

3. Correct Installation: Guarantee that the mold is precisely installed on the Pellet Press, averting equipment damage or experimental accidents resulting from improper installation.

4. Pressure Adjustment: Based on the properties of the materials and the requisite hardness of the samples, appropriately modify the pressure setting of the Pellet Press..

5. Material preparation: Ensure that the material is homogeneously mixed without agglomeration to facilitate a smooth pressing process.

6. Overload prevention: Do not exceed the rated load of the Pellet Press when using the mold to avoid equipment damage.

7. Operating procedures: Operators should be familiar with the operating procedures of the Pellet Press and the mold and operate in accordance with the standard operating processes.

8. Safety protection: During the operation, appropriate personal protective equipment such as safety glasses and gloves should be worn.

9. Mold replacement: When replacing the mold, ensure that the Pellet Press is in a stopped state and all pressure has been released.

keyword:

RUISCI

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Detachable Mold,Applicable to RUISCI Pellet Press

- Subtitle: Detachable Mold,Applicable to RUISCI Pellet Press

- Model: CM-S

- 全部型号: CM-S-01,CM-S-02,CM-S-03,CM-S-04,CM-S-05,CM-S-06,CM-S-07,CM-S-08,CM-S-09,CM-S-10,CM-S-11,CM-S-12,CM-S-13,CM-S-14,CM-S-15,CM-S-16,

Detachable Mold is a specific type of laboratory mold that is usually utilized in pellet presses for the production of sample pieces of particular shapes.

Detachable Mold is a specific type of laboratory mold that is usually utilized in pellet presses for the production of sample pieces of particular shapes. The structure of this mold is composed of several components and can be disassembled conveniently, facilitating the demolding of the finished sample pieces. In the pelletizing process, after the material is filled into the mold cavity, pressure is exerted to shape the material into sample pieces. Once the shaping is accomplished and the mold is disassembled, the sample pieces can be extracted smoothly. This mold is applicable for the preparation of sample bottles with complex shapes and high demands for demolding, effectively enhancing the efficiency of preparation and the quality of sample pieces. This mold is specifically dedicated for RUISCI Pellet Press.

-

1. Facilitated Demolding: The detachable mold enables the formed sample pieces to be extracted effortlessly, minimizing the phenomenon of mold adhesion and enhancing production efficiency.

2. High Applicability: It is capable of manufacturing complex and unconventional-shaped sample pieces, satisfying diverse product requirements, such as polygonal ones, those with grooves or raised patterns, etc.

3. High Precision: The components are closely coordinated, guaranteeing the dimensional accuracy and shape consistency of the sample pieces and ensuring product quality.

4. Excellent Durability: Commonly fabricated from premium steel and other materials, and subjected to precise processing and heat treatment, it exhibits high strength and wear resistance, featuring a long service life.

5. Convenient Maintenance: The combined structure is relatively straightforward, facilitating disassembly and cleaning, and incurring relatively low daily maintenance costs. -

Precautions:

1. Mold cleaning: The mold should be thoroughly cleaned before and after use to prevent cross-contamination and prolong its service life.

2. Mold condition inspection: Regularly check the mold for wear, cracks, or other damages to ensure its good condition.

3. Correct Installation: Guarantee that the mold is precisely installed on the Pellet Press, averting equipment damage or experimental accidents resulting from improper installation.

4. Pressure Adjustment: Based on the properties of the materials and the requisite hardness of the samples, appropriately modify the pressure setting of the Pellet Press..

5. Material preparation: Ensure that the material is homogeneously mixed without agglomeration to facilitate a smooth pressing process.

6. Overload prevention: Do not exceed the rated load of the Pellet Press when using the mold to avoid equipment damage.

7. Operating procedures: Operators should be familiar with the operating procedures of the Pellet Press and the mold and operate in accordance with the standard operating processes.

8. Safety protection: During the operation, appropriate personal protective equipment such as safety glasses and gloves should be worn.

9. Mold replacement: When replacing the mold, ensure that the Pellet Press is in a stopped state and all pressure has been released.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation