Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Ultrasonic Cleaner

Ultrasonic Cleaner

RKQ

-

Click to select

- RKQ-01E,0.8L,LED

- RKQ1133,1.3L

- RKQ2200,2L

- RKQ3322,3.2L

- RKQ6655,6.5L

- RKQ-10,10L

- RKQ-15,15L

- RKQ-22,22L

- RKQ-30,30L

- RKQ-01A,1.3L,LED

- RKQ-02A,2L,LED

- RKQ-03A,3.2L,LED

- RKQ-07A,6.5L,LED

- RKQ-10A,10L,LED

- RKQ-15A,15L,LED

- RKQ-22A,22L,LED

- RKQ-30A,30L,LED

Inventory

4556

隐藏域元素占位

Overview

The Ultrasonic Cleaner is a laboratory cleaning apparatus that employs the principle of ultrasonic vibration to clean various instruments, containers, and tools. Its operational mechanism involves generating a 'cavitation effect' through the propagation of ultrasonic waves in the cleaning liquid medium. This process creates microscale shock waves and high-speed jets that act upon the surface of the object being cleaned, effectively dislodging contaminants and achieving high-quality, high-efficiency cleaning results.

Features

1. High-Efficiency Cleaning: Ultrasonic Cleaner are capable of cleaning a large quantity of items within a short period, thereby enhancing cleaning efficiency.

2. Deep Cleaning: Ultrasonic waves can permeate the minute crevices and holes of the items, eliminating dirt that is otherwise inaccessible.

3. Non-Contact Cleaning: During the cleaning process, direct contact with the items is not necessary, minimizing physical damage to them.

4. Environmental Friendliness and Energy Conservation: In contrast to traditional cleaning methods, Ultrasonic Cleaner typically consume less cleaning agents and water resources, being more environmentally friendly.

5. Simple Operation: A significant number of Ultrasonic Cleaner adopt automated control, facilitating simple operation and ease of use.

6. Versatility: They are applicable for the cleaning of various materials and items, including metals, glass, and plastics.

7. Outstanding Cleaning Effects: Ultrasonic Cleaner can attain high-standard cleaning quality and remove stubborn stains.

8. Low Maintenance Costs: Owing to their durability and reliability, the maintenance costs of Ultrasonic Cleaner are relatively low.

9. High Safety: During the cleaning process, operators do not need to have direct contact with chemical cleaning agents, reducing safety risks.

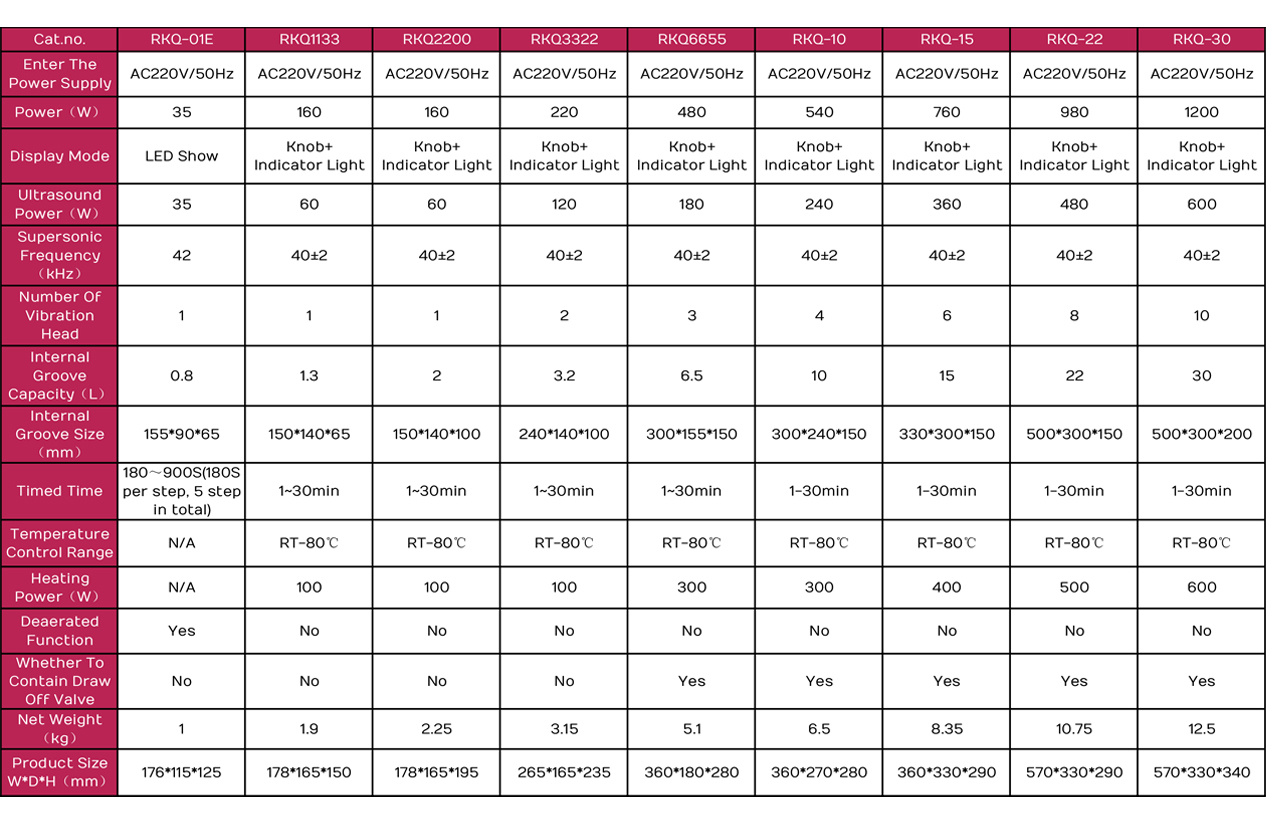

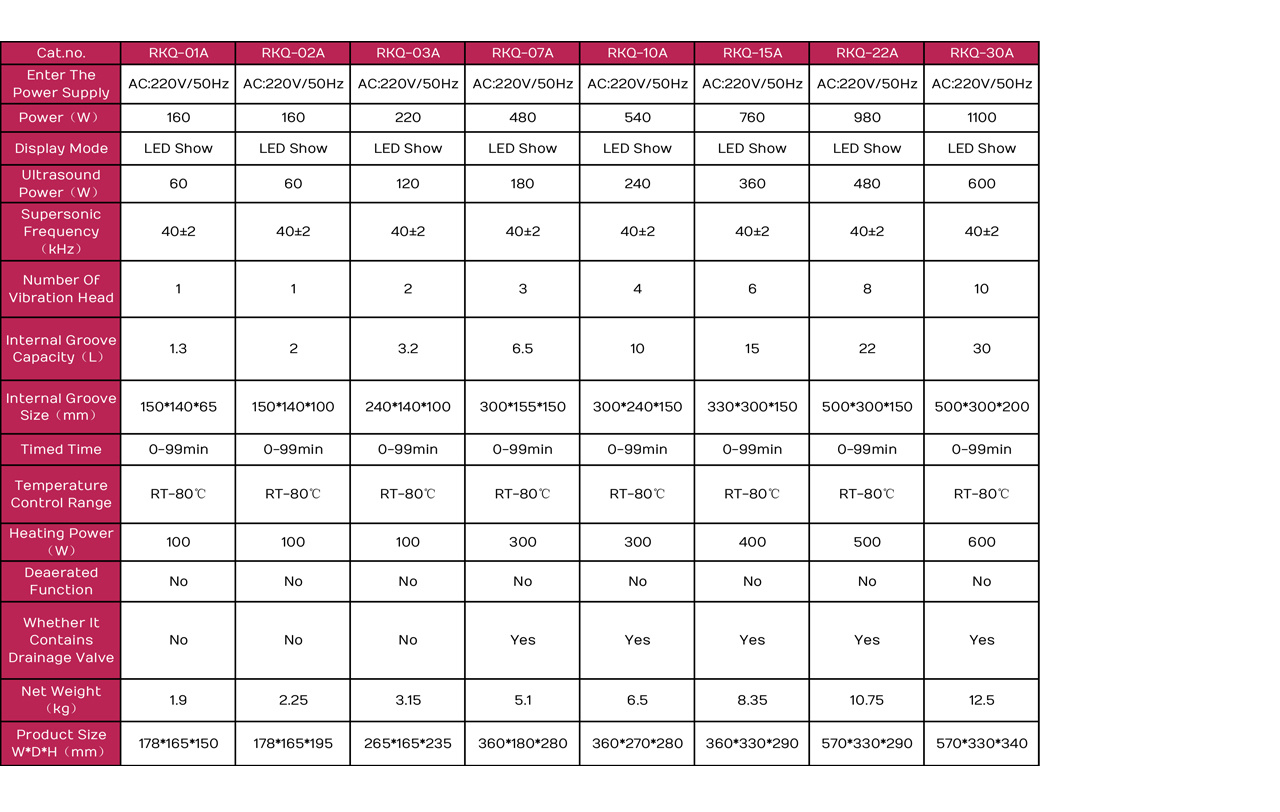

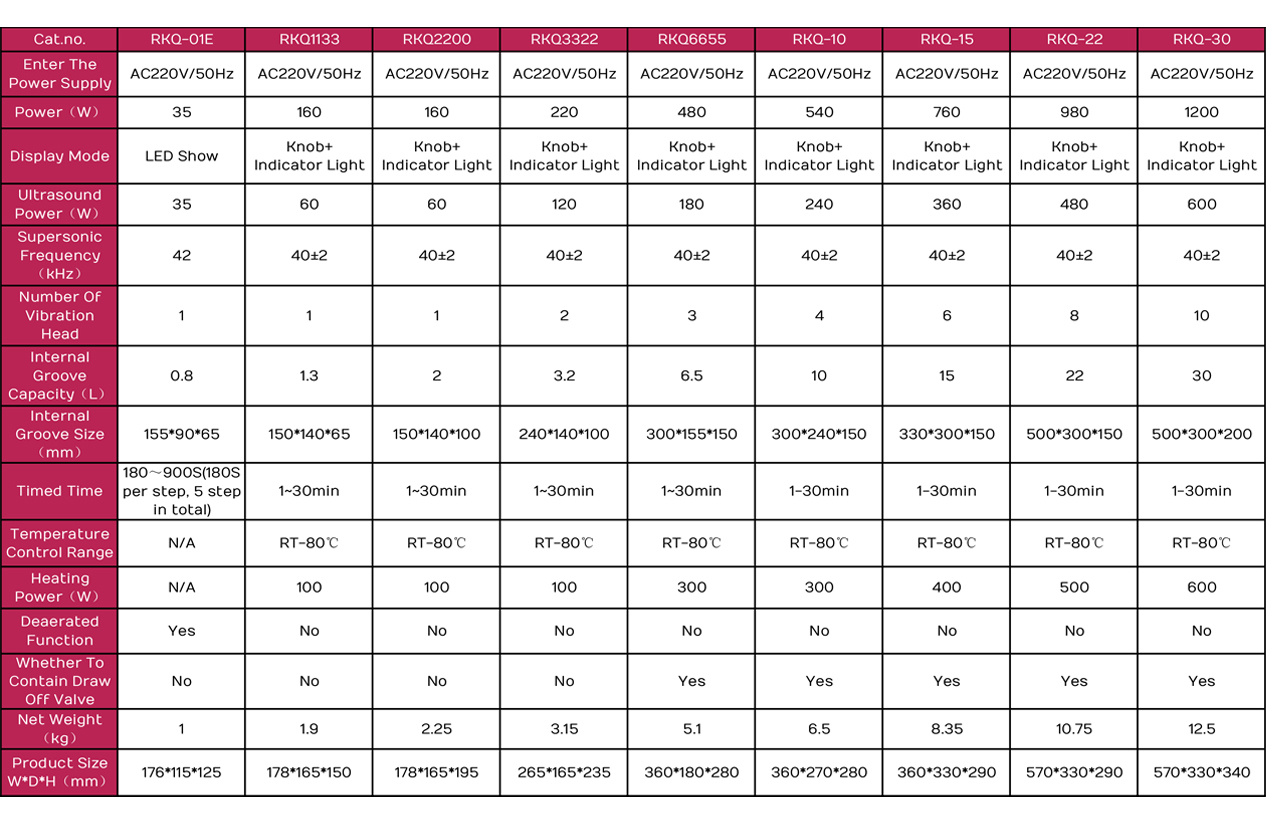

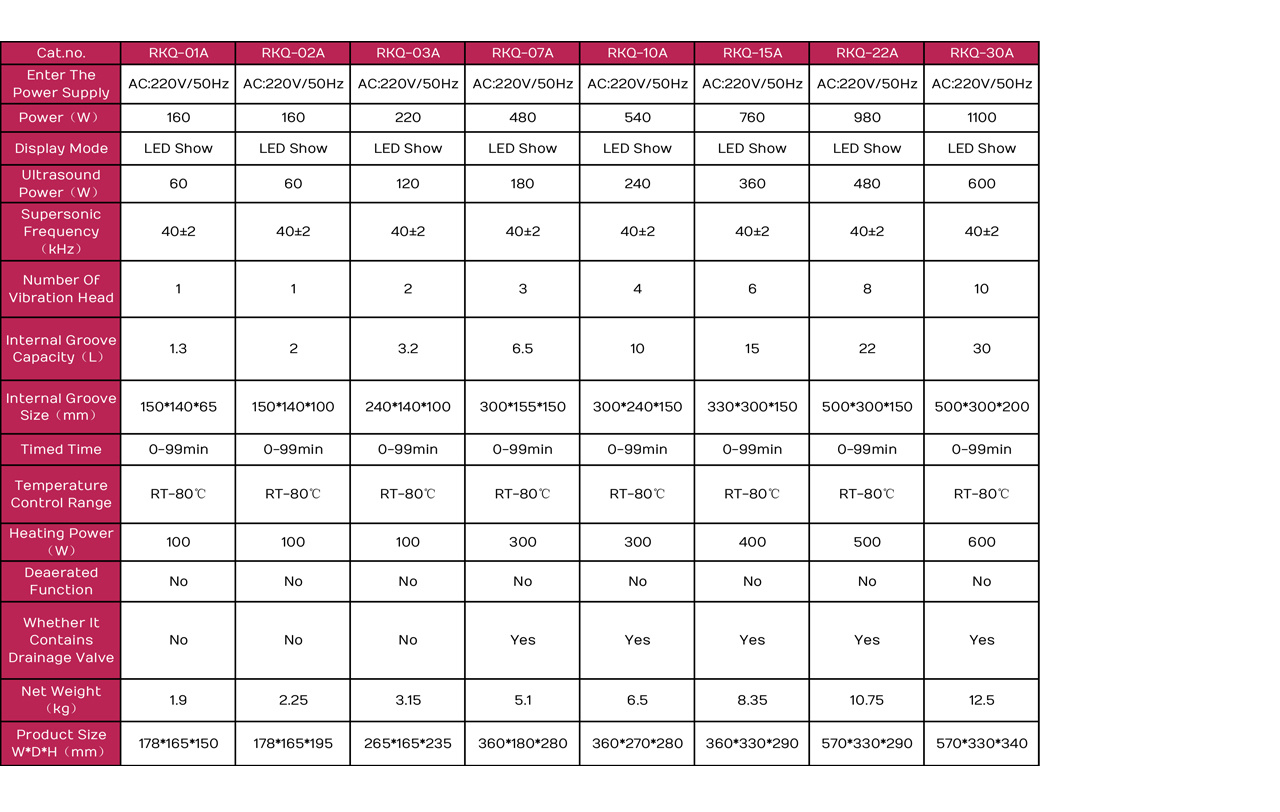

Technical data

Working Environment Conditions:

1. Ambient Temperature: Generally, it should range from 10°C to 40°C to guarantee the normal operation of the equipment and the accuracy of temperature control.

2. Relative Humidity: The relative humidity of the working environment should not exceed 85% to avoid dampness, leakage or damage to the equipment caused by excessive humidity.

3. Placement Requirements: It should be placed on a level, flat, dry and anti-skid ground. The workbench should be set in a location with minimal vibration interference, and the workshop should be kept clean and dry.

4. Safety Distance: The equipment should not be placed close to heat sources. The instrument must not be used in areas with explosive hazards, and must not be used for an extended period in environments with high humidity or high dust.

5. Ventilation Conditions: Due to the grease coating on the surface of the glass fiber, white smoke and an unpleasant smell may occur during the first use. It should be placed in a well-ventilated area and can be used normally after the smoke and smell disappear within several minutes.

6. Grounding Requirements: This product must be grounded. When stored, it should be dry and not be exposed to moisture.

Precautions:

1. Container Selection: The heating container should be compatible with the electric heating mantle. The bottom of the container should be flat and neither too large nor too small. When using a glass container, direct contact between the container and the inner sleeve of the electric heating mantle should be avoided. Thermal insulation materials such as asbestos nets can be placed at the bottom.

2. Heating Operation: Heating should be carried out gradually to prevent container breakage or sample splashing due to sudden temperature rise. During the heating process, close attention should be paid to temperature changes to prevent damage to samples or equipment due to excessive temperature.

3. Stirring Operation: If the electric heating mantle is equipped with a stirring function, ensure that the stirrer can rotate freely after being placed in the container and avoid collision with the container wall or bottom. The stirring speed should be adjusted appropriately according to the experimental requirements and the nature of the sample.

4. Cleaning and Maintenance: Dirt and residues on the surface of the electric heating mantle should be cleaned promptly after use to keep the equipment clean. The heating elements and temperature control system of the electric heating mantle should be inspected regularly to ensure their normal operation.

5. Safety Protection: Appropriate protective equipment such as gloves and goggles should be worn during operation to avoid burns from high temperatures and corrosion from chemical reagents. When heating volatile, toxic or corrosive substances, the operation should be conducted in a fume hood and corresponding protective measures should be taken.

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Commodity name: Ultrasonic Cleaner

- Subtitle: Ultrasonic Cleaner

- Model: RKQ

- 全部型号: RKQ-01E,RKQ1133,RKQ2200,RKQ3322,RKQ6655,RKQ-10,RKQ-15,RKQ-22,RKQ-30,RKQ-01A,RKQ-02A,RKQ-03A,RKQ-07A,RKQ-10A,RKQ-15A,RKQ-22A,RKQ-30A,

The Ultrasonic Cleaner is a laboratory cleaning apparatus that employs the principle of ultrasonic vibration to clean various instruments, containers, and tools.

The Ultrasonic Cleaner is a laboratory cleaning apparatus that employs the principle of ultrasonic vibration to clean various instruments, containers, and tools. Its operational mechanism involves generating a 'cavitation effect' through the propagation of ultrasonic waves in the cleaning liquid medium. This process creates microscale shock waves and high-speed jets that act upon the surface of the object being cleaned, effectively dislodging contaminants and achieving high-quality, high-efficiency cleaning results.

-

1. High-Efficiency Cleaning: Ultrasonic Cleaner are capable of cleaning a large quantity of items within a short period, thereby enhancing cleaning efficiency.

2. Deep Cleaning: Ultrasonic waves can permeate the minute crevices and holes of the items, eliminating dirt that is otherwise inaccessible.

3. Non-Contact Cleaning: During the cleaning process, direct contact with the items is not necessary, minimizing physical damage to them.

4. Environmental Friendliness and Energy Conservation: In contrast to traditional cleaning methods, Ultrasonic Cleaner typically consume less cleaning agents and water resources, being more environmentally friendly.

5. Simple Operation: A significant number of Ultrasonic Cleaner adopt automated control, facilitating simple operation and ease of use.

6. Versatility: They are applicable for the cleaning of various materials and items, including metals, glass, and plastics.

7. Outstanding Cleaning Effects: Ultrasonic Cleaner can attain high-standard cleaning quality and remove stubborn stains.

8. Low Maintenance Costs: Owing to their durability and reliability, the maintenance costs of Ultrasonic Cleaner are relatively low.

9. High Safety: During the cleaning process, operators do not need to have direct contact with chemical cleaning agents, reducing safety risks. -

Working Environment Conditions:

1. Ambient Temperature: Generally, it should range from 10°C to 40°C to guarantee the normal operation of the equipment and the accuracy of temperature control.

2. Relative Humidity: The relative humidity of the working environment should not exceed 85% to avoid dampness, leakage or damage to the equipment caused by excessive humidity.

3. Placement Requirements: It should be placed on a level, flat, dry and anti-skid ground. The workbench should be set in a location with minimal vibration interference, and the workshop should be kept clean and dry.

4. Safety Distance: The equipment should not be placed close to heat sources. The instrument must not be used in areas with explosive hazards, and must not be used for an extended period in environments with high humidity or high dust.

5. Ventilation Conditions: Due to the grease coating on the surface of the glass fiber, white smoke and an unpleasant smell may occur during the first use. It should be placed in a well-ventilated area and can be used normally after the smoke and smell disappear within several minutes.

6. Grounding Requirements: This product must be grounded. When stored, it should be dry and not be exposed to moisture.Precautions:

1. Container Selection: The heating container should be compatible with the electric heating mantle. The bottom of the container should be flat and neither too large nor too small. When using a glass container, direct contact between the container and the inner sleeve of the electric heating mantle should be avoided. Thermal insulation materials such as asbestos nets can be placed at the bottom.

2. Heating Operation: Heating should be carried out gradually to prevent container breakage or sample splashing due to sudden temperature rise. During the heating process, close attention should be paid to temperature changes to prevent damage to samples or equipment due to excessive temperature.

3. Stirring Operation: If the electric heating mantle is equipped with a stirring function, ensure that the stirrer can rotate freely after being placed in the container and avoid collision with the container wall or bottom. The stirring speed should be adjusted appropriately according to the experimental requirements and the nature of the sample.

4. Cleaning and Maintenance: Dirt and residues on the surface of the electric heating mantle should be cleaned promptly after use to keep the equipment clean. The heating elements and temperature control system of the electric heating mantle should be inspected regularly to ensure their normal operation.

5. Safety Protection: Appropriate protective equipment such as gloves and goggles should be worn during operation to avoid burns from high temperatures and corrosion from chemical reagents. When heating volatile, toxic or corrosive substances, the operation should be conducted in a fume hood and corresponding protective measures should be taken.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation