Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Microwave Digestion System

Microwave Digestion System

RMD-A,RAE-A,

Brand:

RUISCI

-

Click to select

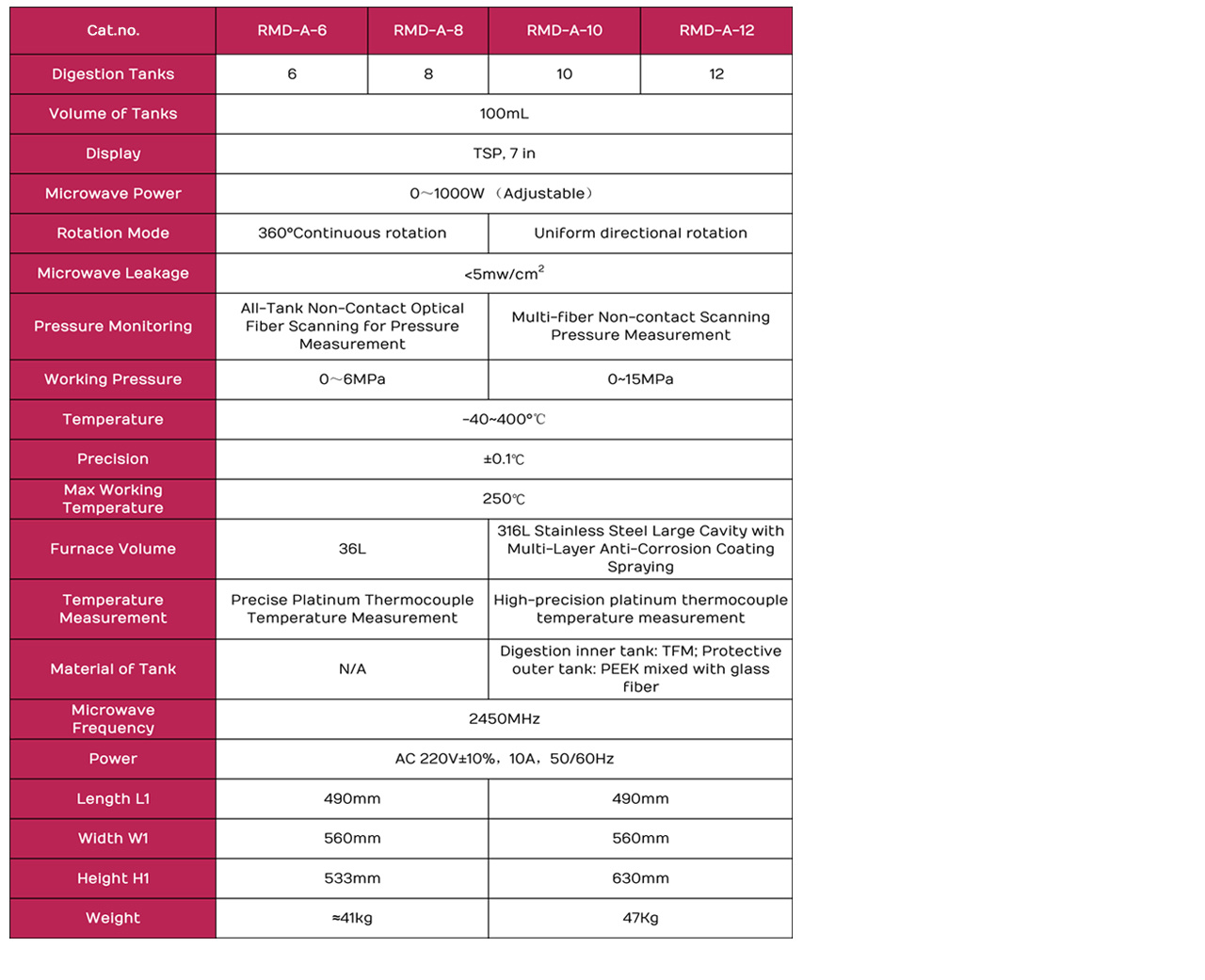

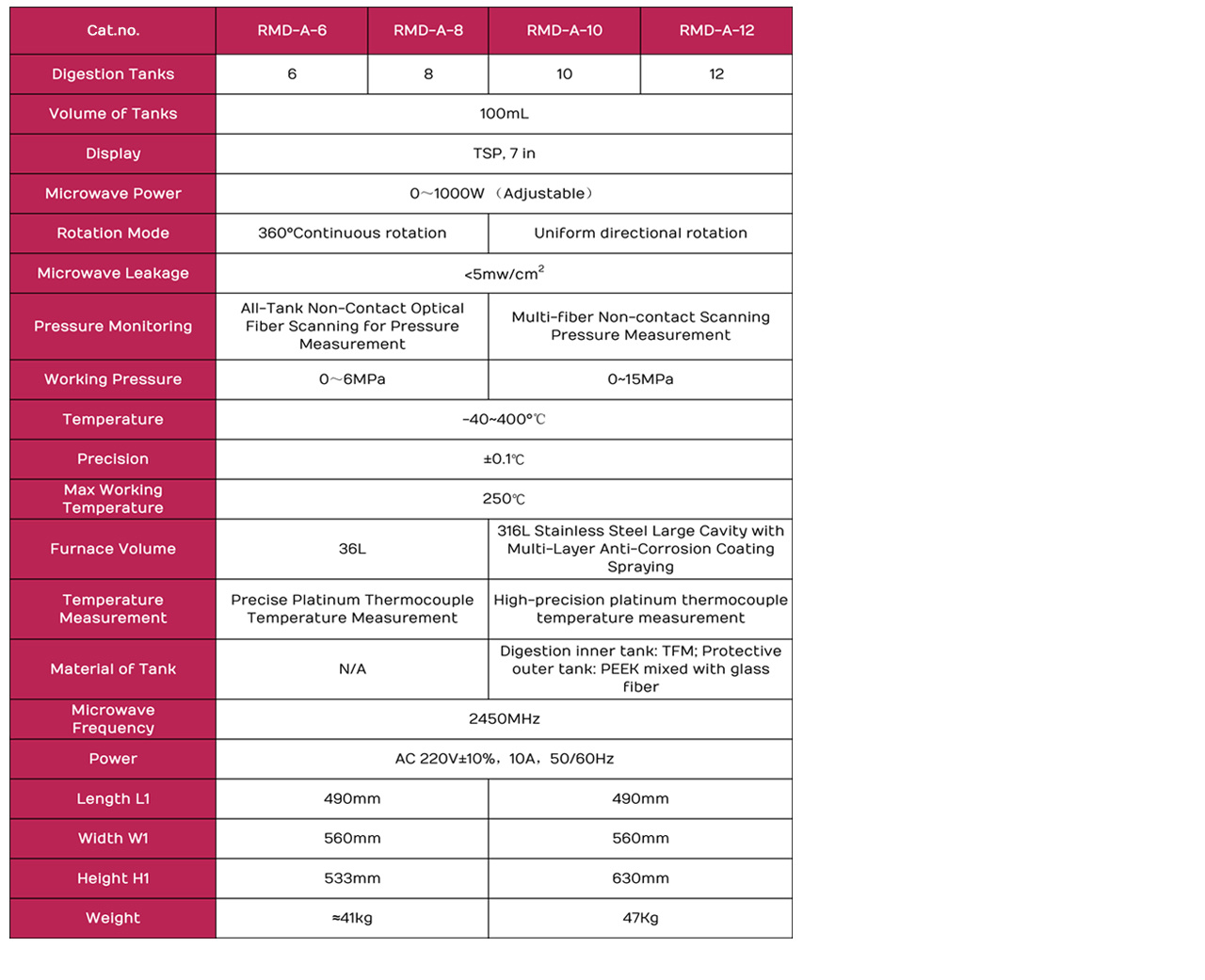

- RMD-A-6,6Tanks

- RMD-A-8,8Tanks

- RMD-A-10,10Tanks

- RMD-A-12,12Tanks

- RAE-A-01,12(mini)Hole,Regular

- RAE-A-02,12Hole,Regular

- RAE-A-03,20Hole,Regular

- RAE-A-04,56Hole,Regular

Inventory

1344

隐藏域元素占位

Overview

The Microwave Digestion System is an analytical pretreatment apparatus that utilizes microwave energy to heat and digest samples within a sealed container. Its operational principle is predicated on the thermal and non-thermal effects of microwaves, enabling a rapid temperature increase of the sample and acid mixture, disrupting the sample matrix, and converting the elements under determination into soluble ions. It is extensively applied in domains such as laboratories, environmental monitoring, food safety, pharmaceutical analysis, materials science, and is suitable for sample preparation for instruments like atomic absorption, plasma spectroscopy, the combination of plasma spectroscopy and mass spectrometry, gas chromatography, and the combination of gas chromatography and mass spectrometry.

Features

1. Microwave Technology: A vertical waveguide design and three-dimensional output technique are employed to achieve a highly uniform microwave field.

2. Temperature Control System: It is furnished with a high-precision temperature control system capable of real-time monitoring, control, and display of the temperature and temperature curve within the digestion tank.

3. Pressure Control System: A non-contact pressure control system is available, enabling real-time monitoring, control, and display of the pressure and pressure curve within the digestion tank.

4. Structural Materials: The entire machine housing is fabricated from carbon fiber-reinforced polymer materials, featuring high structural strength.

5. Explosion-proof Cavity: A 316L stainless steel explosion-proof cavity is utilized, possessing multiple layers of anti-corrosion and high-temperature resistant coatings.

6. Cost Reduction: The design eliminates the need for consumables such as explosion-proof membranes and sealing bowls, thereby reducing the cost of later maintenance.

7. User Interface: All are equipped with a 7-inch oversized touch screen, offering a friendly human-computer interaction interface.

8. Software Functionality: The software library stores multiple internationally common standard application methods, allowing users to customize, edit, store, modify, and delete application methods.

9. Electromagnetic Protection: Professional electromagnetic protection design is incorporated, adhering to high-end microwave leakage protection standards.

Technical data

Working Environmental Conditions:

1. Ambient Temperature: It is advisable to be within the range of 20℃ ± 10℃ to evade the influence of extreme temperatures on the equipment's performance.

2. Relative Humidity: It ought to be maintained below 80% without condensation to prevent damage to the equipment caused by moisture.

3. Ventilation Circumstance: The instrument should be placed on a solid and well-ventilated workstation to facilitate heat dissipation.

4. Power Supply Requirements: An independent and stable power supply should be utilized to preclude the impact of power fluctuations on the equipment's performance.

5. Safety Requirements: The instrument should be kept at a distance from strong magnetic fields and high-power equipment to prevent magnetic field interference and electromagnetic wave leakage.

Precautions:

1. Training: Ensure that the operators have undergone appropriate training to comprehend the correct usage of the equipment and the countermeasures in emergency situations.

2. Equipment Inspection: Before utilization, inspect whether the microwave digestion apparatus is operating normally, including the power supply, microwave system, temperature control, and pressure control systems.

3. Sample Preparation: Ensure that the samples are prepared accurately and avoid the use of flammable, explosive, or microwave-sensitive samples.

4. Appropriate Containers: Employ containers specifically designed for microwave digestion, such as digestion vessels fabricated from polytetrafluoroethylene (PTFE) or borosilicate glass.

5. Sample Volume Control: Do not exceed one-third of the digestion vessel's capacity to avoid excessive pressure generation during digestion.

6. Acid Utilization: Be cautious when using acids and avoid the employment of strong oxidizing acids, such as nitric acid, unless under strictly controlled conditions.

7. Sealing Check: Ensure that the digestion vessels have satisfactory sealing to prevent leakage under high temperatures and pressures.

8. Temperature and Pressure Settings: Set the temperature and pressure parameters correctly in accordance with the sample type and digestion method.

9. Process Monitoring: During the digestion process, monitor the equipment's status periodically to ensure normal operation.

10. Cooling: After digestion, allow the samples to cool naturally within the microwave digestion instrument to avoid pressure variations resulting from rapid cooling.

11. Cleaning and Maintenance: Clean the digestion vessels and the equipment after use and conduct regular maintenance inspections to ensure the long-term stable operation of the equipment.

12. Safety Protection: Wear appropriate personal protective equipment, such as laboratory safety glasses and gloves, during the operation.

keyword:

Previous:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Microwave Digestion System

- Subtitle: Microwave Digestion System

- Model: RMD-A,RAE-A,

- 全部型号: RMD-A-6,RMD-A-8,RMD-A-10,RMD-A-12,RAE-A-01,RAE-A-02,RAE-A-03,RAE-A-04

The Microwave Digestion System is an analytical pretreatment apparatus that utilizes microwave energy to heat and digest samples within a sealed container.

The Microwave Digestion System is an analytical pretreatment apparatus that utilizes microwave energy to heat and digest samples within a sealed container. Its operational principle is predicated on the thermal and non-thermal effects of microwaves, enabling a rapid temperature increase of the sample and acid mixture, disrupting the sample matrix, and converting the elements under determination into soluble ions. It is extensively applied in domains such as laboratories, environmental monitoring, food safety, pharmaceutical analysis, materials science, and is suitable for sample preparation for instruments like atomic absorption, plasma spectroscopy, the combination of plasma spectroscopy and mass spectrometry, gas chromatography, and the combination of gas chromatography and mass spectrometry.

-

1. Microwave Technology: A vertical waveguide design and three-dimensional output technique are employed to achieve a highly uniform microwave field.

2. Temperature Control System: It is furnished with a high-precision temperature control system capable of real-time monitoring, control, and display of the temperature and temperature curve within the digestion tank.

3. Pressure Control System: A non-contact pressure control system is available, enabling real-time monitoring, control, and display of the pressure and pressure curve within the digestion tank.

4. Structural Materials: The entire machine housing is fabricated from carbon fiber-reinforced polymer materials, featuring high structural strength.

5. Explosion-proof Cavity: A 316L stainless steel explosion-proof cavity is utilized, possessing multiple layers of anti-corrosion and high-temperature resistant coatings.

6. Cost Reduction: The design eliminates the need for consumables such as explosion-proof membranes and sealing bowls, thereby reducing the cost of later maintenance.

7. User Interface: All are equipped with a 7-inch oversized touch screen, offering a friendly human-computer interaction interface.

8. Software Functionality: The software library stores multiple internationally common standard application methods, allowing users to customize, edit, store, modify, and delete application methods.

9. Electromagnetic Protection: Professional electromagnetic protection design is incorporated, adhering to high-end microwave leakage protection standards. -

Working Environmental Conditions:

1. Ambient Temperature: It is advisable to be within the range of 20℃ ± 10℃ to evade the influence of extreme temperatures on the equipment's performance.

2. Relative Humidity: It ought to be maintained below 80% without condensation to prevent damage to the equipment caused by moisture.

3. Ventilation Circumstance: The instrument should be placed on a solid and well-ventilated workstation to facilitate heat dissipation.

4. Power Supply Requirements: An independent and stable power supply should be utilized to preclude the impact of power fluctuations on the equipment's performance.

5. Safety Requirements: The instrument should be kept at a distance from strong magnetic fields and high-power equipment to prevent magnetic field interference and electromagnetic wave leakage.Precautions:

1. Training: Ensure that the operators have undergone appropriate training to comprehend the correct usage of the equipment and the countermeasures in emergency situations.

2. Equipment Inspection: Before utilization, inspect whether the microwave digestion apparatus is operating normally, including the power supply, microwave system, temperature control, and pressure control systems.

3. Sample Preparation: Ensure that the samples are prepared accurately and avoid the use of flammable, explosive, or microwave-sensitive samples.

4. Appropriate Containers: Employ containers specifically designed for microwave digestion, such as digestion vessels fabricated from polytetrafluoroethylene (PTFE) or borosilicate glass.

5. Sample Volume Control: Do not exceed one-third of the digestion vessel's capacity to avoid excessive pressure generation during digestion.

6. Acid Utilization: Be cautious when using acids and avoid the employment of strong oxidizing acids, such as nitric acid, unless under strictly controlled conditions.

7. Sealing Check: Ensure that the digestion vessels have satisfactory sealing to prevent leakage under high temperatures and pressures.

8. Temperature and Pressure Settings: Set the temperature and pressure parameters correctly in accordance with the sample type and digestion method.

9. Process Monitoring: During the digestion process, monitor the equipment's status periodically to ensure normal operation.

10. Cooling: After digestion, allow the samples to cool naturally within the microwave digestion instrument to avoid pressure variations resulting from rapid cooling.

11. Cleaning and Maintenance: Clean the digestion vessels and the equipment after use and conduct regular maintenance inspections to ensure the long-term stable operation of the equipment.

12. Safety Protection: Wear appropriate personal protective equipment, such as laboratory safety glasses and gloves, during the operation.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation