Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Hot Mounting Press

Hot Mounting Press

RHM-M,RHM-A

Brand:

RUISCI

-

Click to select

- RHM-M-01,φ22mm,Manual

- RHM-M-02,φ30mm,Manual

- RHM-M-03,φ45mm,Manual

- RHM-A-01,φ22mm,Automatic

- RHM-A-02,φ30mm,Automatic

- RHM-A-03,φ45mm,Automatic

- RHM-A-04,With Water Cooling

- RHM-A-05,With Two Inlaid Positions

- RHM-A-06,Adjustable Steel Sleeve

Inventory

1512

隐藏域元素占位

Overview

The Hot Mounting Press is a device employed for embedding specimens in thermosetting or thermoplastic substances. It constitutes a procedural stage prior to sample grinding and polishing, being applicable for embedding minute, unhandy, or irregular metallographic and petrographic specimens. Once embedded, the specimens can undergo grinding and polishing operations, and it is beneficial for the normal observation of the material's microstructure under a metallographic microscope. This machine is capable of automatically heating and applying pressure. Upon the completion of pressing and shaping, it will automatically cease operation and release the pressure. By pressing the button again, the automatically pressed specimen will ascend automatically, and the specimen can thereby be obtained. It is extensively utilized in domains such as metallographic analysis and material testing.

Features

1. High Efficiency: The heating and pressurization processes are swift, considerably shortening the preparation time of specimens.

2. Precise Control: It is furnished with an exact temperature and pressure control system, ensuring the stability of embedding quality.

3. High Degree of Automation: Adopting full automatic control, with automatic heating, automatic pressurization, and automatic sample output, the operation is facile and unattended operation can be realized.

4. Cooling System: Equipped with an efficient cooling system, which can rapidly lower the temperature and improve the efficiency of sample preparation.

5. Strong Adaptability: It is applicable to the embedding of multiple materials, including metals, ceramics, and other hard materials.

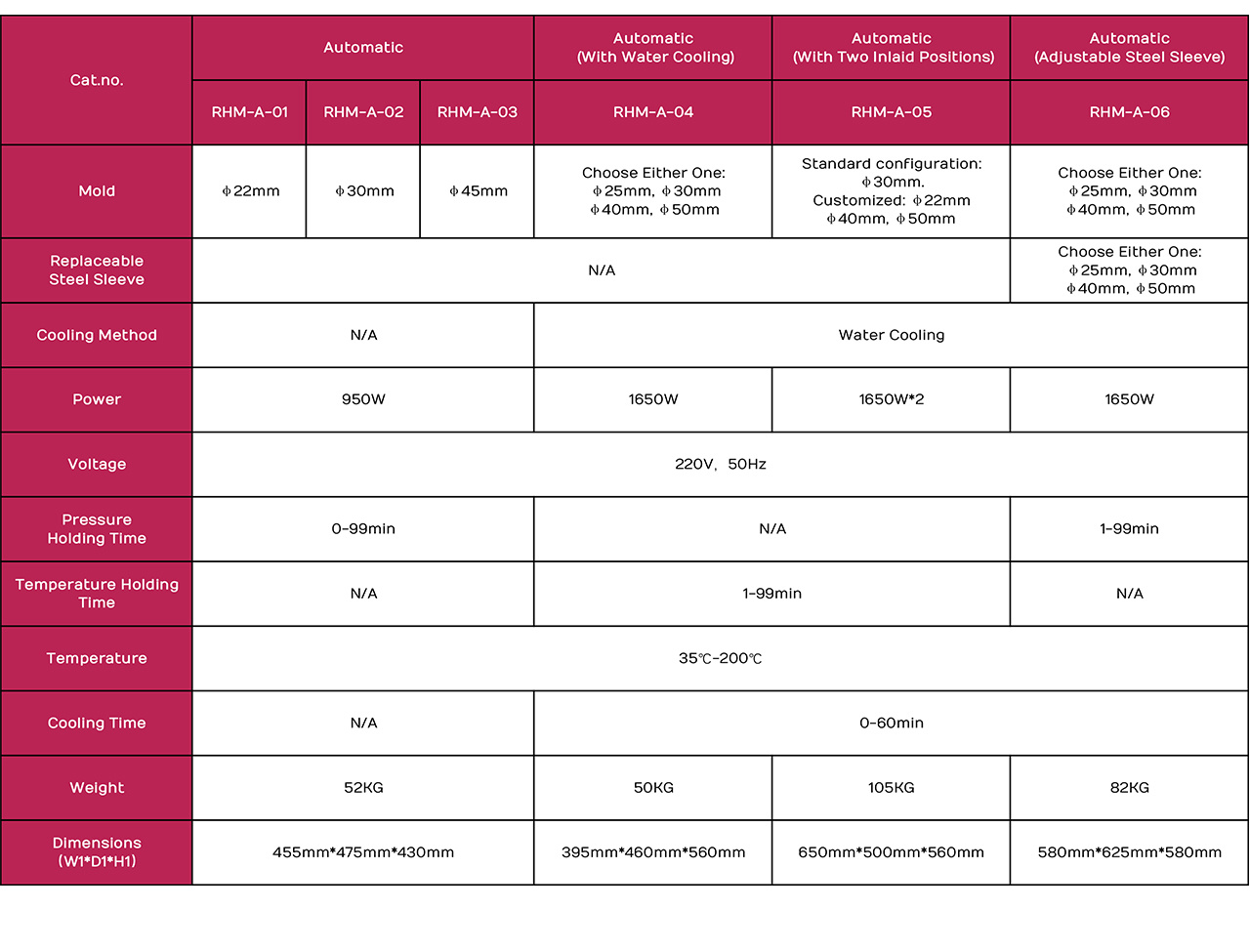

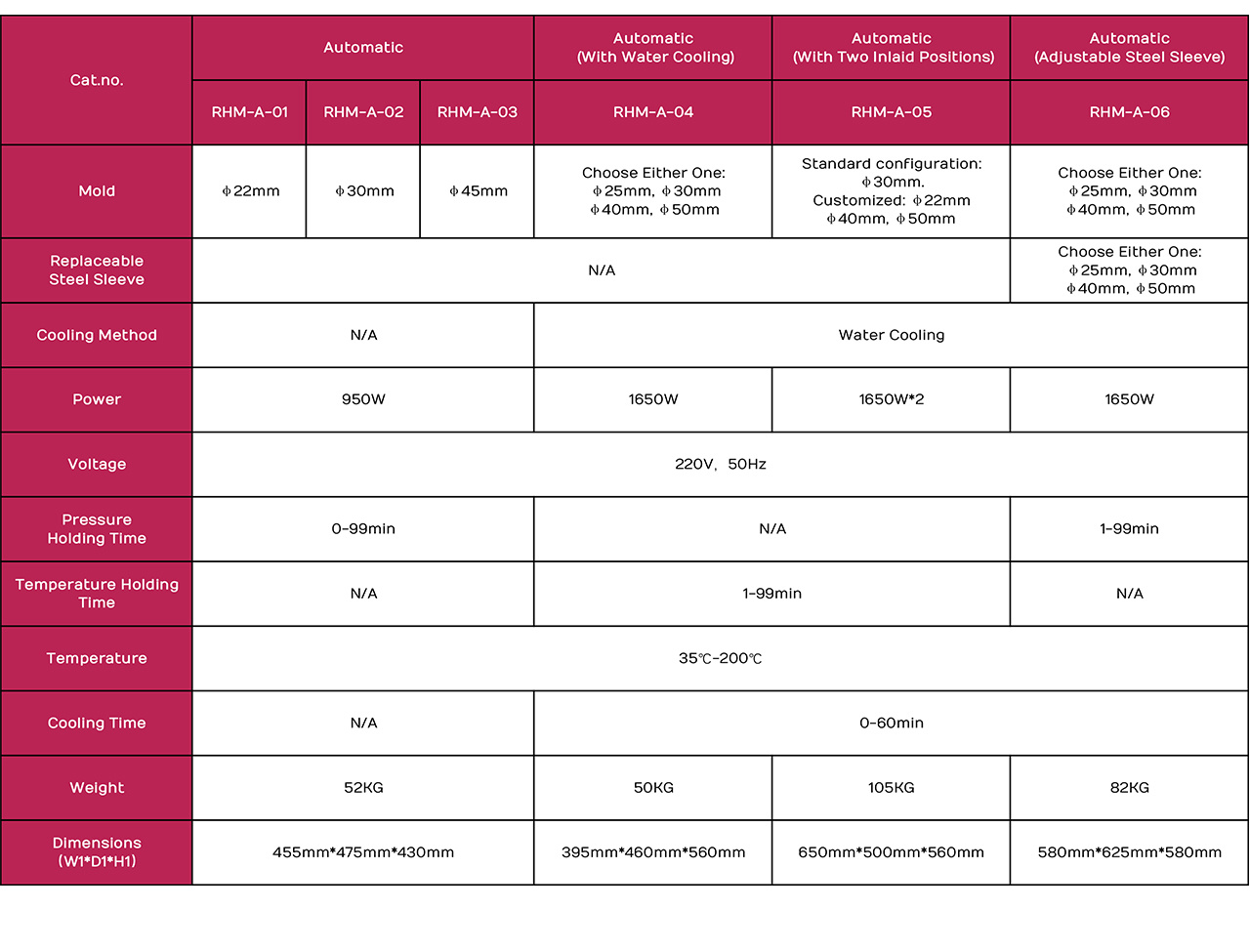

Technical data

Working Environment Conditions:

1. Ambient Temperature: It is advisable to range from 5°C to 40°C to preclude any adverse impact on the equipment's performance.

2. Relative Humidity: The relative humidity should fall within the range of 30% to 90% without condensation, in order to prevent moisture from causing damage to the equipment.

3. Ventilation Environment: Ensure that the working environment is well-ventilated to avoid the accumulation of heat or volatile substances generated during the operation.

4. Power Supply Requirements: An independent and stable power supply should be utilized to prevent power fluctuations from influencing the equipment's performance.

5. Cooling System: The instrument is furnished with a water cooling system, and appropriate cooling water inlet and drainage pipelines are necessary.

Precautions:

1. Equipment Inspection: Before utilization, inspect whether the power supply, heating components, pressure system, and cooling system are operating normally.

2. Mold Cleaning: Clean the inlay cavity and the mold to prevent residue from influencing the inlay quality.

3. Preparation of Inlay Material: Ensure the inlay material is dry, impurity-free, and suitable for the sample type.

4. Wearing Protective Equipment: When operating, wear protective gloves and goggles to prevent scalding or chemical harm.

5. Parameter Setting: Based on the requirements of the sample and the inlay material, set appropriate temperatures and pressures.

6. Correct Sample Placement: Position the sample at the center of the mold to ensure accurate positioning after inlaying.

7. Attention to Heating and Cooling: During the heating process, avoid frequent opening of the cover. During cooling, select an appropriate method and ensure the normal operation of the cooling system.

8. Cleaning and Maintenance: Promptly clean the equipment after operation. Regularly inspect components such as the sealing ring and pressure gauge, and conduct timely maintenance.

9. Adherence to Safety Regulations: Be familiar with the location of the emergency stop button, stay away from flammable items, avoid non-compliant operations, and ensure operational safety.

keyword:

Metallographic Hot Mounting Insights

Metallography Hot Mounting Presses

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Hot Mounting Press

- Subtitle: Hot Mounting Press

- Model: RHM-M,RHM-A

- 全部型号: RHM-M-01,RHM-M-02,RHM-M-03,RHM-A-01,RHM-A-02,RHM-A-03,RHM-A-04,RHM-A-05,RHM-A-06 Hot Mounting Press hot mounting insight Specimen Hot Mounting Presses Metallography Hot Mounting Presses Metallographic Hot Mounting Insights

The Hot Mounting Press is a device employed for embedding specimens in thermosetting or thermoplastic substances.

The Hot Mounting Press is a device employed for embedding specimens in thermosetting or thermoplastic substances. It constitutes a procedural stage prior to sample grinding and polishing, being applicable for embedding minute, unhandy, or irregular metallographic and petrographic specimens. Once embedded, the specimens can undergo grinding and polishing operations, and it is beneficial for the normal observation of the material's microstructure under a metallographic microscope. This machine is capable of automatically heating and applying pressure. Upon the completion of pressing and shaping, it will automatically cease operation and release the pressure. By pressing the button again, the automatically pressed specimen will ascend automatically, and the specimen can thereby be obtained. It is extensively utilized in domains such as metallographic analysis and material testing.

-

1. High Efficiency: The heating and pressurization processes are swift, considerably shortening the preparation time of specimens.

2. Precise Control: It is furnished with an exact temperature and pressure control system, ensuring the stability of embedding quality.

3. High Degree of Automation: Adopting full automatic control, with automatic heating, automatic pressurization, and automatic sample output, the operation is facile and unattended operation can be realized.

4. Cooling System: Equipped with an efficient cooling system, which can rapidly lower the temperature and improve the efficiency of sample preparation.

5. Strong Adaptability: It is applicable to the embedding of multiple materials, including metals, ceramics, and other hard materials. -

Working Environment Conditions:

1. Ambient Temperature: It is advisable to range from 5°C to 40°C to preclude any adverse impact on the equipment's performance.

2. Relative Humidity: The relative humidity should fall within the range of 30% to 90% without condensation, in order to prevent moisture from causing damage to the equipment.

3. Ventilation Environment: Ensure that the working environment is well-ventilated to avoid the accumulation of heat or volatile substances generated during the operation.

4. Power Supply Requirements: An independent and stable power supply should be utilized to prevent power fluctuations from influencing the equipment's performance.

5. Cooling System: The instrument is furnished with a water cooling system, and appropriate cooling water inlet and drainage pipelines are necessary.

Precautions:

1. Equipment Inspection: Before utilization, inspect whether the power supply, heating components, pressure system, and cooling system are operating normally.

2. Mold Cleaning: Clean the inlay cavity and the mold to prevent residue from influencing the inlay quality.

3. Preparation of Inlay Material: Ensure the inlay material is dry, impurity-free, and suitable for the sample type.

4. Wearing Protective Equipment: When operating, wear protective gloves and goggles to prevent scalding or chemical harm.

5. Parameter Setting: Based on the requirements of the sample and the inlay material, set appropriate temperatures and pressures.

6. Correct Sample Placement: Position the sample at the center of the mold to ensure accurate positioning after inlaying.

7. Attention to Heating and Cooling: During the heating process, avoid frequent opening of the cover. During cooling, select an appropriate method and ensure the normal operation of the cooling system.

8. Cleaning and Maintenance: Promptly clean the equipment after operation. Regularly inspect components such as the sealing ring and pressure gauge, and conduct timely maintenance.

9. Adherence to Safety Regulations: Be familiar with the location of the emergency stop button, stay away from flammable items, avoid non-compliant operations, and ensure operational safety.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation