Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Reaction Kettle

Reaction Kettle

RRK-A

Brand:

RUISCI

-

Click to select

- RRK-A-01,1L

- RRK-A-02,2L

- RRK-A-03,3L

- RRK-A-05,5L

- RRK-A-10,10L

- RRK-A-20,20L

- RRK-A-30,30L

Inventory

1176

隐藏域元素占位

Overview

Reaction Kettle is primarily employed in experiments involving material synthesis, distillation, concentration, and other experiments, widely used in chemical, biological, pharmaceutical and other fields of experimental equipment.

Features

1. The entire machine is constructed using high-quality 304 stainless steel, aluminum alloy, and novel synthetic materials. These materials endow the machine with excellent corrosion and rust resistance properties, enabling it to endure various solvents.

2. All glass components are fabricated from high borosilicate glass. This glass is suitable for use with all media, excluding hydrofluoric acid, hot phosphoric acid, and high-temperature concentrated alkalis.

3. The variable-frequency speed-regulating motor features a brushless design, eliminating sparks and reducing noise levels. With a pure copper core, it can achieve high rotational speeds. The enlarged turbine contributes to the motor's safety, stability, and extended service life.

4. PTFE and specialty rubber composite seals ensure chemical resistance against a wide range of solvents while maintaining high vacuum integrity. Easy to install and replace.

5. The vertical high-efficiency condenser is designed to achieve a high recovery rate.

6. The machine is equipped with universal wheels with foot brakes, facilitating easy movement.

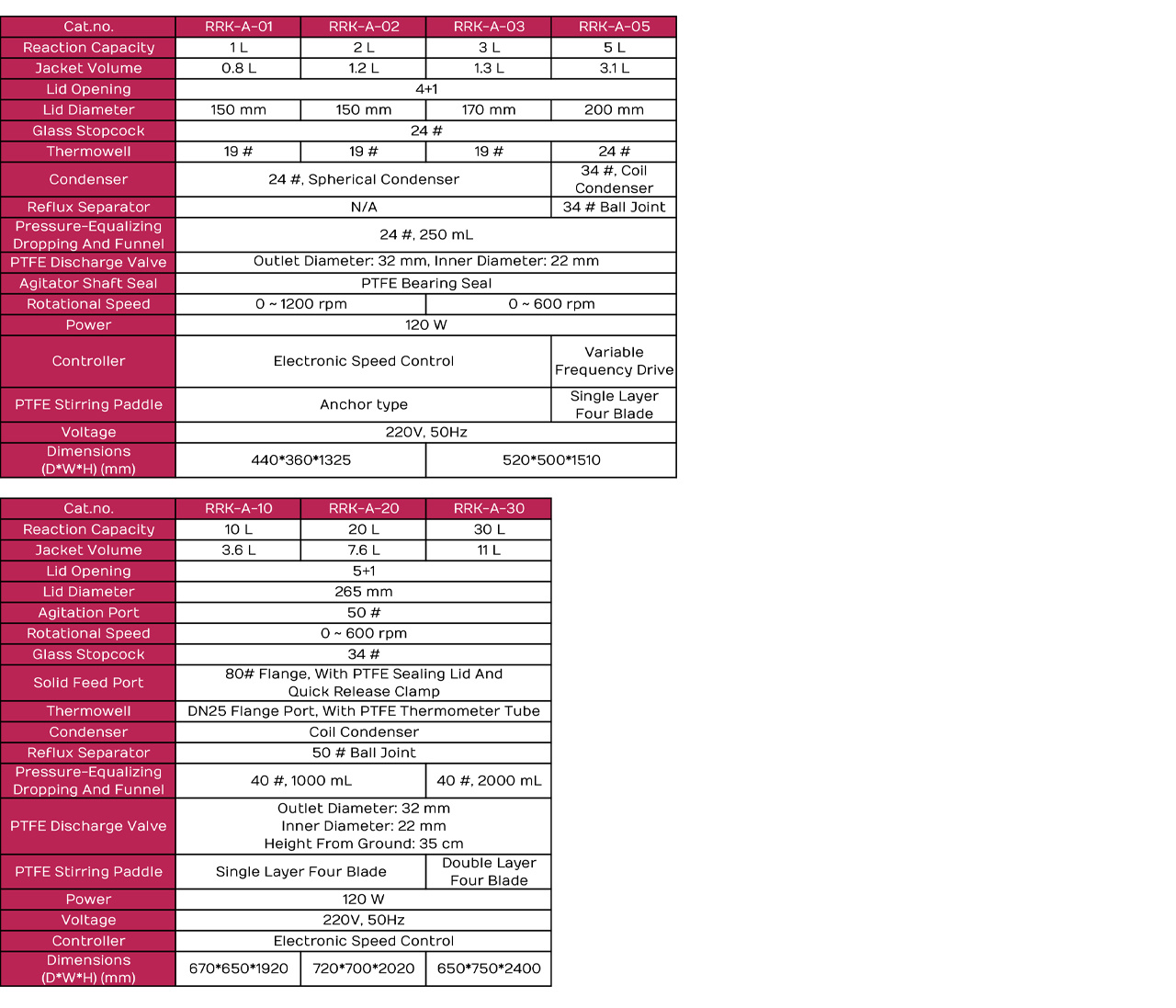

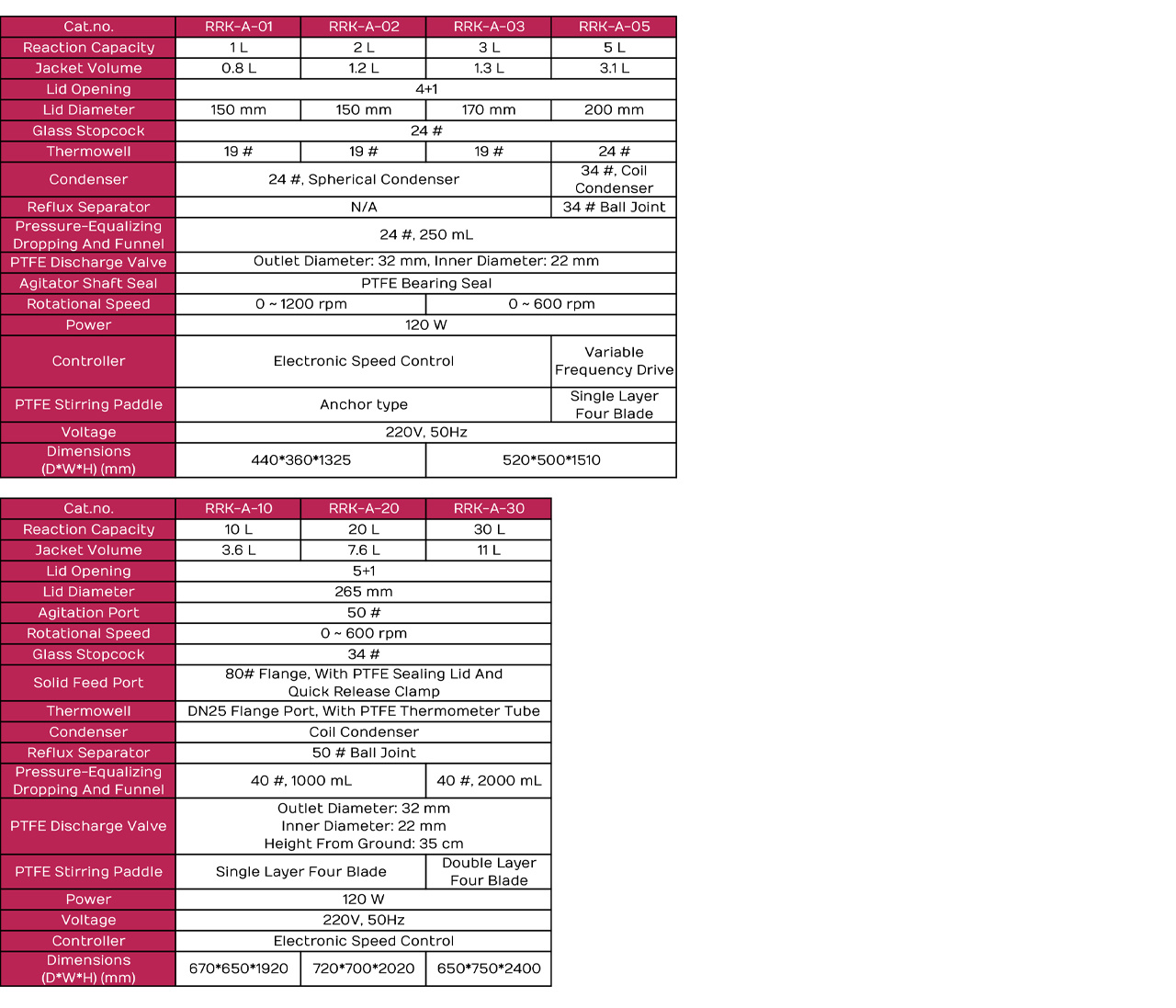

Technical data

Precautions:

1. Conduct a meticulous inspection of the inner and outer walls of the glass reaction kettle for cracks, bubbles, or damage, with particular attention to the integrity of the glass layer. Verify the proper fit of all interfaces, ensuring no signs of looseness or leakage.

2. Examine the power cord for signs of aging, damage, or exposure, and ensure a secure connection of the plug. Confirm that the power supply voltage aligns with the equipment requirements, and take precautions to prevent the electrical components from being exposed to moisture.

3. Manually rotate the stirring shaft to ensure smooth rotation without collision with the thermowell. Check that the stirring paddle is vertically and securely fixed, ensuring concentricity.

4. Inspect all interfaces for proper alignment. Wipe each interface with a soft cloth and apply an appropriate amount of vacuum grease to enhance the sealing performance.

5. Ascertain the compatibility of the reactants and solvents with the material of the reaction kettle to avoid corrosion.

6. Ensure that the volume of the material does not exceed two-thirds of the kettle's volume for liquid substances or one-half for solid substances or reactions that generate gas, leaving sufficient space for expansion.

7. Tighten the bolts evenly and symmetrically to ensure that the sealing ring lies flat without distortion. Gradually increase pressure and temperature to avoid sudden changes that may compromise sealing integrity. Never exceed 80% of the vessel's design pressure.

8. Refrain from running the equipment at high speeds under no-load conditions to prevent damage to the motor.

9. Avoid over-tightening PTFE switches (such as the discharge valve) to prevent damage to the glass components. After shutdown, loosen all PTFE switches to prevent piston deformation due to prolonged static conditions.

10. During operation, if it is necessary to close the jacket circulation ports simultaneously, install and open a pressure relief valve between the valve and the circulation port to prevent pressure build-up and potential rupture of the jacket.

11. After each use, select an appropriate solvent based on the nature of the residues for cleaning. Gently wipe the surfaces with a soft cloth or sponge to avoid scratching the glass. After cleaning, ensure thorough drying of the interior and exterior of the reaction kettle to prevent water accumulation over time.

keyword:

Reaction Kettle

Reactor Vessel

Glass Reaction Vessel

Lab Reaction Vessel

Glass Reactor

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Reaction Kettle

- Subtitle: Reaction Kettle

- Model: RRK-A

- 全部型号: RRK-A-01,RRK-A-02,RRK-A-03,RRK-A-05,RRK-A-10,RRK-A-20,RRK-A-30,Reaction Kettle, Reactor Vessel, Glass Reaction Vessel, Lab Reaction Vessel, Glass Reactor

Reaction Kettle is primarily employed in experiments involving material synthesis, distillation, concentration, and other experiments, widely used in chemical, biological, pharmaceutical and other fields of experimental equipment.

Reaction Kettle is primarily employed in experiments involving material synthesis, distillation, concentration, and other experiments, widely used in chemical, biological, pharmaceutical and other fields of experimental equipment.

-

1. The entire machine is constructed using high-quality 304 stainless steel, aluminum alloy, and novel synthetic materials. These materials endow the machine with excellent corrosion and rust resistance properties, enabling it to endure various solvents.

2. All glass components are fabricated from high borosilicate glass. This glass is suitable for use with all media, excluding hydrofluoric acid, hot phosphoric acid, and high-temperature concentrated alkalis.

3. The variable-frequency speed-regulating motor features a brushless design, eliminating sparks and reducing noise levels. With a pure copper core, it can achieve high rotational speeds. The enlarged turbine contributes to the motor's safety, stability, and extended service life.

4. PTFE and specialty rubber composite seals ensure chemical resistance against a wide range of solvents while maintaining high vacuum integrity. Easy to install and replace.

5. The vertical high-efficiency condenser is designed to achieve a high recovery rate.

6. The machine is equipped with universal wheels with foot brakes, facilitating easy movement. -

Precautions:

1. Conduct a meticulous inspection of the inner and outer walls of the glass reaction kettle for cracks, bubbles, or damage, with particular attention to the integrity of the glass layer. Verify the proper fit of all interfaces, ensuring no signs of looseness or leakage.

2. Examine the power cord for signs of aging, damage, or exposure, and ensure a secure connection of the plug. Confirm that the power supply voltage aligns with the equipment requirements, and take precautions to prevent the electrical components from being exposed to moisture.

3. Manually rotate the stirring shaft to ensure smooth rotation without collision with the thermowell. Check that the stirring paddle is vertically and securely fixed, ensuring concentricity.

4. Inspect all interfaces for proper alignment. Wipe each interface with a soft cloth and apply an appropriate amount of vacuum grease to enhance the sealing performance.

5. Ascertain the compatibility of the reactants and solvents with the material of the reaction kettle to avoid corrosion.

6. Ensure that the volume of the material does not exceed two-thirds of the kettle's volume for liquid substances or one-half for solid substances or reactions that generate gas, leaving sufficient space for expansion.

7. Tighten the bolts evenly and symmetrically to ensure that the sealing ring lies flat without distortion. Gradually increase pressure and temperature to avoid sudden changes that may compromise sealing integrity. Never exceed 80% of the vessel's design pressure.

8. Refrain from running the equipment at high speeds under no-load conditions to prevent damage to the motor.

9. Avoid over-tightening PTFE switches (such as the discharge valve) to prevent damage to the glass components. After shutdown, loosen all PTFE switches to prevent piston deformation due to prolonged static conditions.

10. During operation, if it is necessary to close the jacket circulation ports simultaneously, install and open a pressure relief valve between the valve and the circulation port to prevent pressure build-up and potential rupture of the jacket.

11. After each use, select an appropriate solvent based on the nature of the residues for cleaning. Gently wipe the surfaces with a soft cloth or sponge to avoid scratching the glass. After cleaning, ensure thorough drying of the interior and exterior of the reaction kettle to prevent water accumulation over time.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation