Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Plasma Surface Treater

Plasma Surface Treater

RPS-A

Brand:

RUISCI

-

Click to select

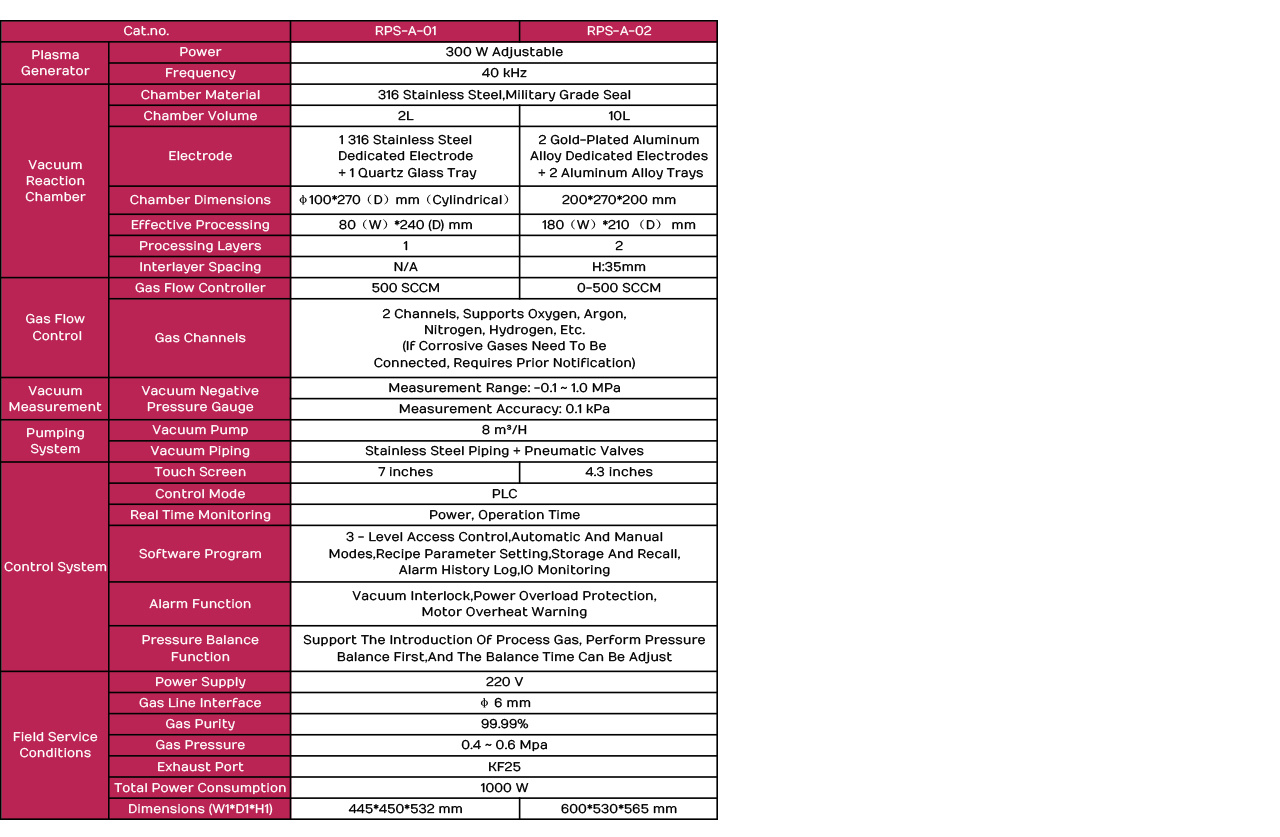

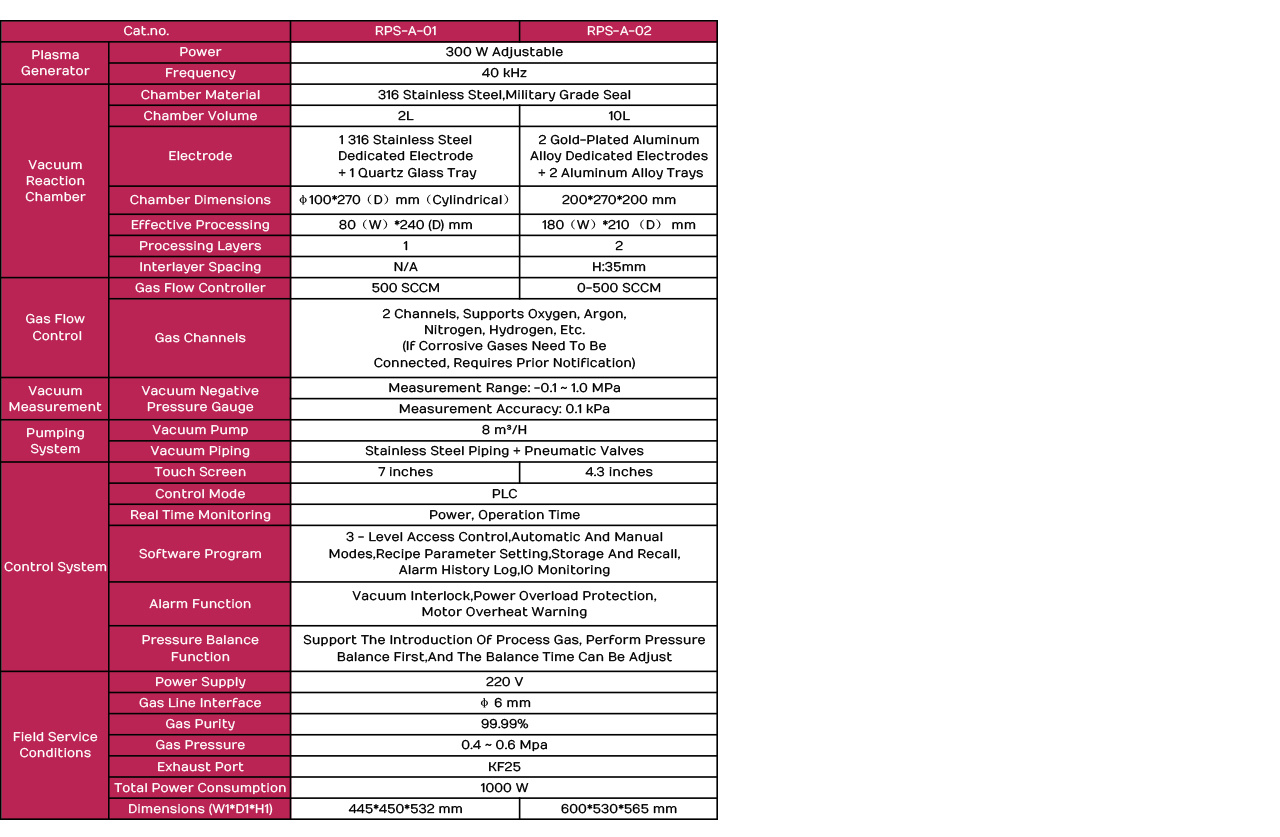

- RPS-A-01,2L

- RPS-A-02,10L

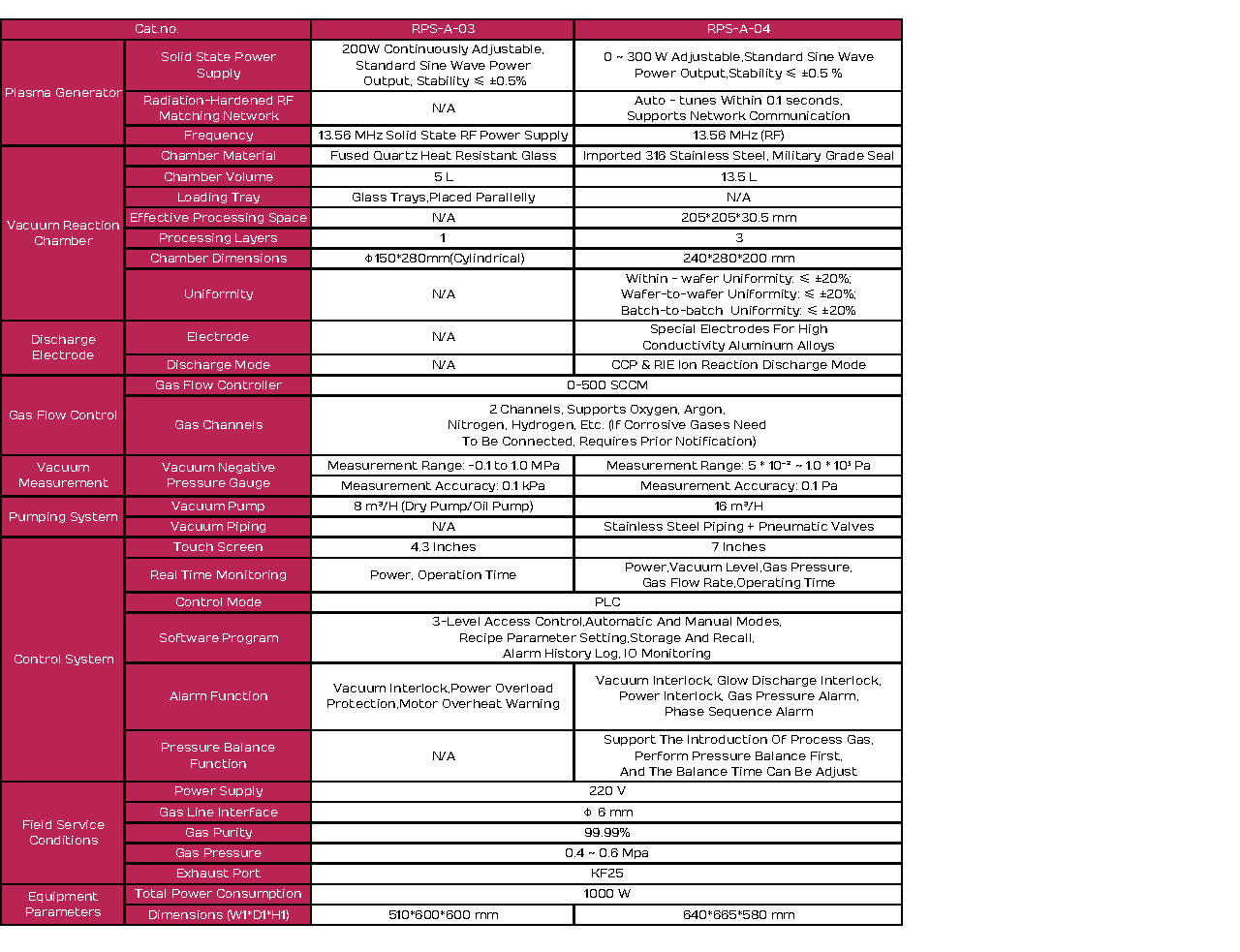

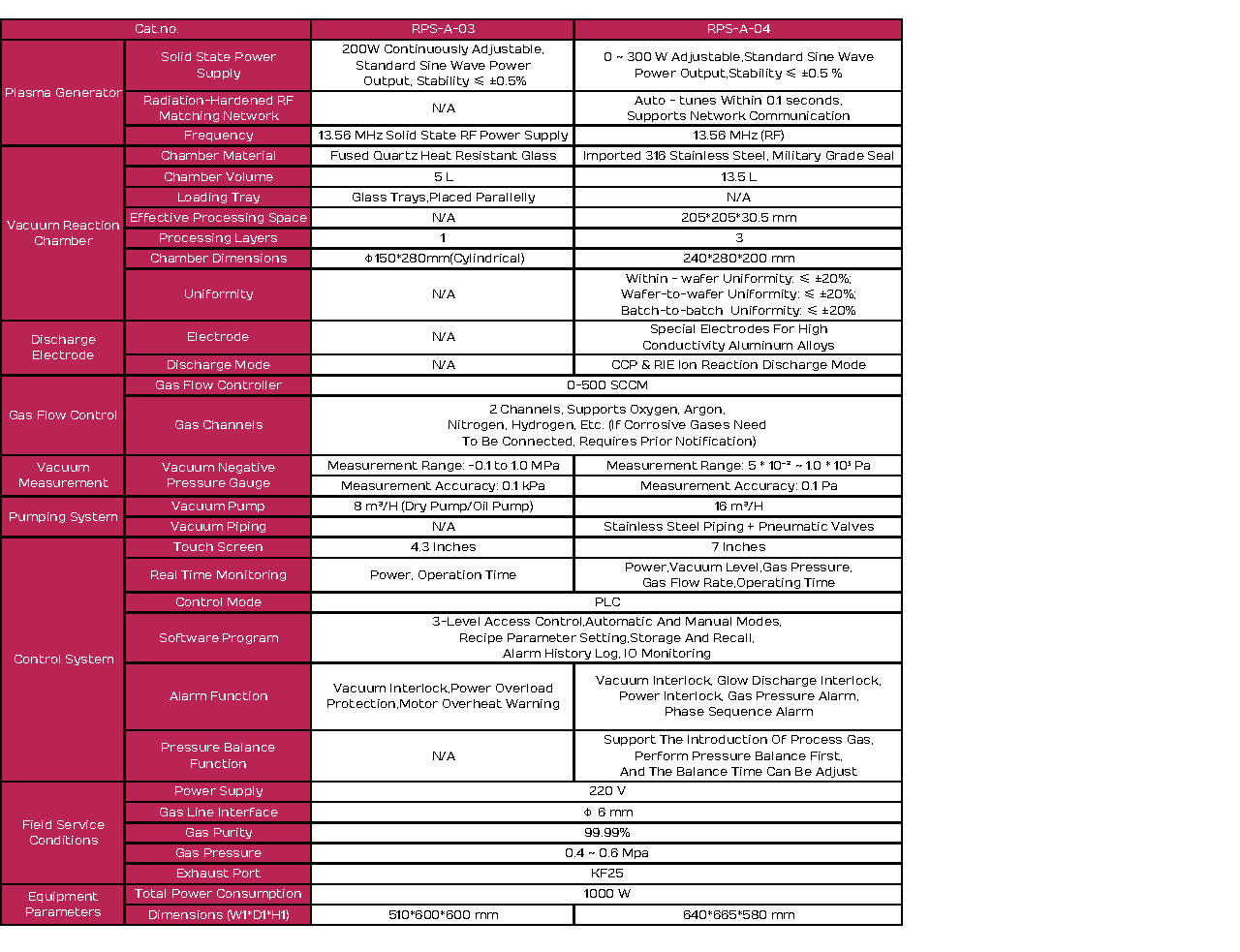

- RPS-A-03,5L

- RPS-A-04,13.5L

Inventory

720

隐藏域元素占位

Overview

This laboratory-grade plasma surface treater is designed for R&D institutions, universities, and small-batch production. Utilizing CCP (Capacitively Coupled Plasma) technology, the system features a cylindrical stainless steel vacuum chamber, integrated plasma generator, vacuum pump, and gas inlet/outlet ports. It enhances substrate surface adhesion and hydrophilicity, making it ideal for material bonding, coating, thin-film deposition, and wafer bonding applications.

Features

1. Stainless steel vacuum chamber, military-grade welding technology, strong chamber sealing, excellent corrosion resistance.

2. Equipped with dual-layer electrode and multi-level treatment plates, effectively improving space utilization.

3. Touchscreen operation interface, user-friendly control, real-time display of process parameters.

4. Can store multiple process recipe data, which can be retrieved for use, and data is traceable.

5. Equipped with two independent gas channels, facilitating exploration of the impact of different gas ratios on cleaning effects.

6. Convection gas distribution system, which can form dynamic circulation and uniform gas intake during cleaning to enhance cleaning effectiveness.

7. Main applications: Cleaning; activation; etching; bonding; photoresist stripping.

8. RPS-A-03 and RPS-A-04 have overvoltage, overcurrent, over-temperature, and reflected power protection.

Technical data

Working environment:

1. Power supply and power: Power supply requirements: 220V, 50/60Hz, grid fluctuation tolerance: ±10%, compliant with grid earthing standards, and must be installed in areas free from strong electromagnetic interference.

2. Installation environment requirements: The ambient temperature should be between 0-40℃, and the humidity should be 15%-60%.

3. Gas source preparation: Oxygen, argon, nitrogen, hydrogen and other gas cylinders (to be used with pressure reducing valves), inlet pressure > 0.3 MPa, gas interface specification: ɸ 6 mm.

4. Exhaust duct: Connect to the exhaust port of the vacuum pump (if required in a clean room environment).

Precautions:

1. Sample placement: Ensure the materials are placed firmly and in appropriate quantities at a time.

2. Operation monitoring: Pay attention to the equipment's operating status. Stop the machine immediately for inspection if any abnormality occurs.

3. Installation environment: The equipment should be placed in a dry, well-ventilated area free from strong magnetic fields and kept away from flammable and explosive materials.

4. Equipment cleaning: Clean the equipment promptly after operation.

5. Waste disposal: Harmful exhaust gases should be connected to a pipeline leading to a treatment pool.

keyword:

Plasma Surface Treater

Plasma surface treatment instrument

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Plasma Surface Treater

- Subtitle: Plasma Surface Treater

- Model: RPS-A

- 全部型号: RPS-A-01,RPS-A-02,RPS-A-03,RPS-A-04,Plasma Surface Treater,Plasma surface treatment instrument

This laboratory-grade plasma surface treater is designed for R&D institutions

This laboratory-grade plasma surface treater is designed for R&D institutions, universities, and small-batch production. Utilizing CCP (Capacitively Coupled Plasma) technology, the system features a cylindrical stainless steel vacuum chamber, integrated plasma generator, vacuum pump, and gas inlet/outlet ports. It enhances substrate surface adhesion and hydrophilicity, making it ideal for material bonding, coating, thin-film deposition, and wafer bonding applications.

-

1. Stainless steel vacuum chamber, military-grade welding technology, strong chamber sealing, excellent corrosion resistance.

2. Equipped with dual-layer electrode and multi-level treatment plates, effectively improving space utilization.

3. Touchscreen operation interface, user-friendly control, real-time display of process parameters.

4. Can store multiple process recipe data, which can be retrieved for use, and data is traceable.

5. Equipped with two independent gas channels, facilitating exploration of the impact of different gas ratios on cleaning effects.

6. Convection gas distribution system, which can form dynamic circulation and uniform gas intake during cleaning to enhance cleaning effectiveness.

7. Main applications: Cleaning; activation; etching; bonding; photoresist stripping.

8. RPS-A-03 and RPS-A-04 have overvoltage, overcurrent, over-temperature, and reflected power protection. -

Working environment:

1. Power supply and power: Power supply requirements: 220V, 50/60Hz, grid fluctuation tolerance: ±10%, compliant with grid earthing standards, and must be installed in areas free from strong electromagnetic interference.

2. Installation environment requirements: The ambient temperature should be between 0-40℃, and the humidity should be 15%-60%.

3. Gas source preparation: Oxygen, argon, nitrogen, hydrogen and other gas cylinders (to be used with pressure reducing valves), inlet pressure > 0.3 MPa, gas interface specification: ɸ 6 mm.

4. Exhaust duct: Connect to the exhaust port of the vacuum pump (if required in a clean room environment).Precautions:

1. Sample placement: Ensure the materials are placed firmly and in appropriate quantities at a time.

2. Operation monitoring: Pay attention to the equipment's operating status. Stop the machine immediately for inspection if any abnormality occurs.

3. Installation environment: The equipment should be placed in a dry, well-ventilated area free from strong magnetic fields and kept away from flammable and explosive materials.

4. Equipment cleaning: Clean the equipment promptly after operation.

5. Waste disposal: Harmful exhaust gases should be connected to a pipeline leading to a treatment pool.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation