Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

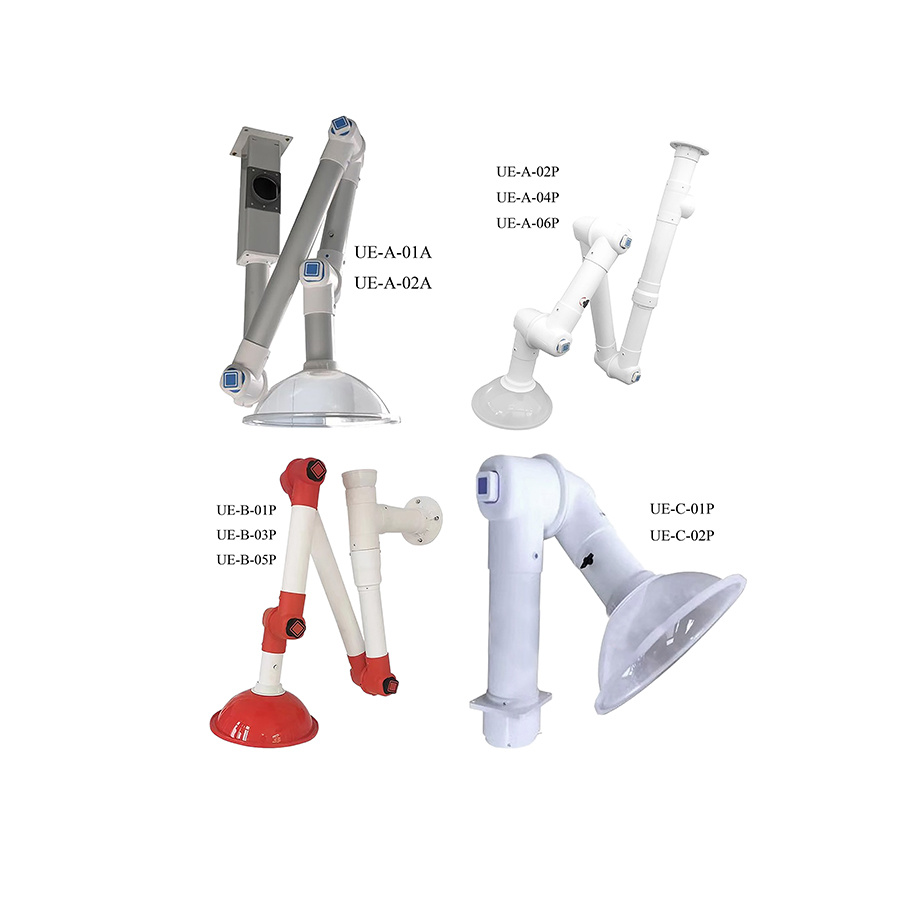

Fixed Gas Detector

Fixed Gas Detector

RFGD-A

Brand:

RUISCI

-

Click to select

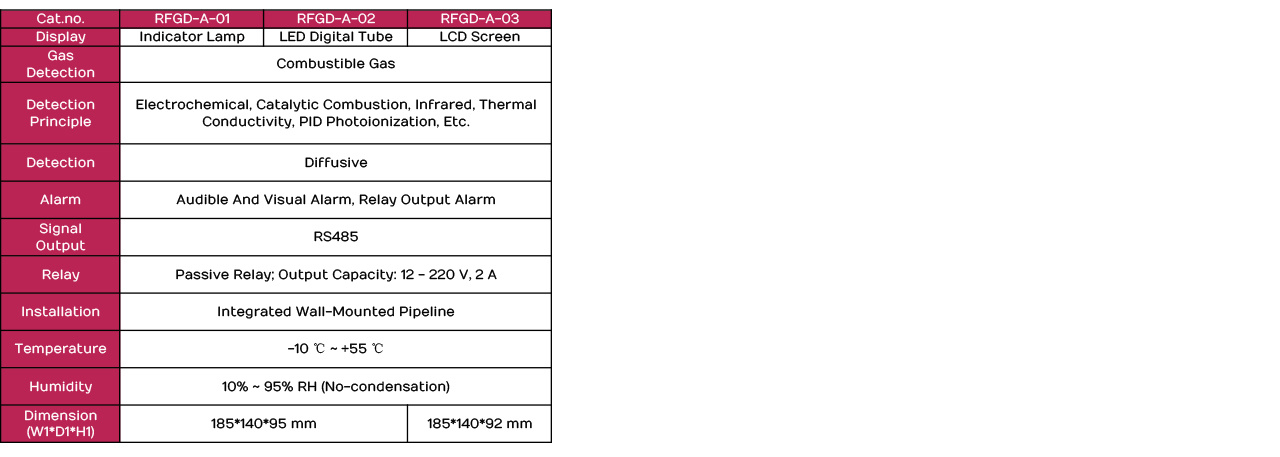

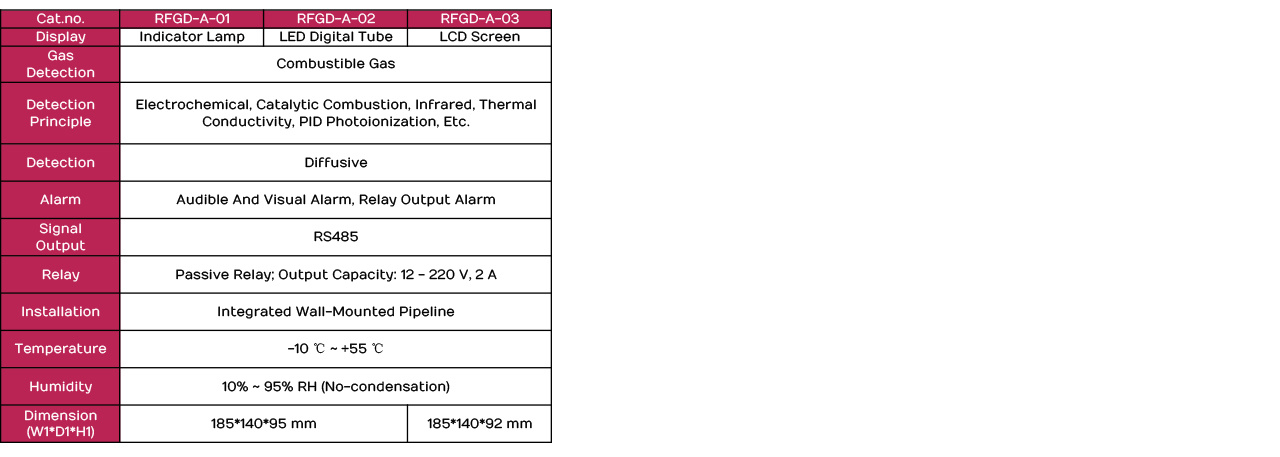

- RFGD-A-01,Indicator Lamp

- RFGD-A-02,LED Digital Tube

- RFGD-A-03,LCD Screen

Inventory

600

隐藏域元素占位

Overview

Fixed Gas Detector is a device installed at a specific location, which is used to continuously monitor the concentration of specific gases in the environment. It can detect combustible gases in real time. When the gas concentration exceeds the set threshold, it will issue an alarm to ensure the safety of personnel and the production environment. It finds extensive applications in numerous scenarios, including metallurgy, petroleum, chemical engineering, mining, coking, municipal engineering, environmental protection, pharmaceutical manufacturing, power generation, shipbuilding, sewage treatment, etc. These are the places where continuous detection of inflammable, explosive, toxic, and harmful gases is essential.

Features

1. High-definition display screen: Real-time display of the measured gas concentration.

2. Audible and visual alarm: Over-limit alarm reminder.

3. Three-proof design: Sealing rings are provided at all connection points for water-proof, dust-proof and explosion-proof purposes.

4. Adopting explosion-proof design, it uses sensors with high sensitivity, fast response speed, strong anti-interference ability and stable performance; the detector outputs RS485 signals.

5. The detector is equipped with a passive relay output function; it supports 1000-meter long-distance output and can be connected to various control systems such as DCS and PLC.

6. It is equipped with alarm lights, fault lights and operation lights for indication, allowing you to directly view the current operating status; the product adopts a high-definition dot-matrix LCD screen.

7. Supports adjustment of two groups of alarm values: low alarm and high alarm.

8. Supports infrared remote control operation, allowing remote control operation without opening the cover in a limited space.

Technical data

1. Excessive or insufficient oxygen content in the atmosphere may affect the readings of combustible gas sensors.

2. Sudden changes in atmospheric pressure may affect the readings of the sensors.

3. Silicone compound vapors can damage catalytic combustion sensors. Please ensure that such substances do not appear in the usage environment.

4. During use, please keep the sensor's air inlet clean. Blockage of the air inlet may cause the detector's readings to be low or even no response.

5. To ensure the safe and reliable use of the detector, the housing should be reliably grounded. Do not disassemble it by yourself.

6. Do not store this detector in high-temperature, high-humidity or strong static environments.

7. Do not use organic solvents or corrosive liquids (such as alcohol, thinner, etc.) to clean the detector components.

8. Users are not allowed to replace the detector's components by themselves.

9. Operating temperature: Electrochemical -10℃ to +55℃; Catalytic combustion -10℃ to +55℃.

10. Operating humidity: 10 to 95% RH (no condensation).

11. Ensure that the gas flowing into the sensor chamber does not contain moisture, oil stains or other impurities or stains that can easily adhere to the sensor surface and cause sensor failure or damage.

12. It is recommended to calibrate the sensor once every 3 to 6 months, depending on the on-site environment, such as whether there is a large or small amount of target detection gas in the on-site environment.

13. The service life of the sensor is approximately 1 to 3 years, and the specific service life is related to the on-site environmental conditions.

14. Do not plug or unplug the sensor while it is powered on, and do not drop or impact it.

15. Avoid frequent exposure of this product with highly concentrated gas samples whose concentration exceeds the detection range, as this will shorten the sensor's lifespan and even damage the sensor.

keyword:

Fixed Gas Detector

Wall-Mounted Gas Detector

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Fixed Gas Detector

- Subtitle: Fixed Gas Detector

- Model: RFGD-A

- 全部型号: RFGD-A-01,RFGD-A-02,RFGD-A-03,Fixed Gas Detector,Wall-Mounted Gas Detector

Fixed Gas Detector is a device installed at a specific location.

Fixed Gas Detector is a device installed at a specific location, which is used to continuously monitor the concentration of specific gases in the environment. It can detect combustible gases in real time. When the gas concentration exceeds the set threshold, it will issue an alarm to ensure the safety of personnel and the production environment. It finds extensive applications in numerous scenarios, including metallurgy, petroleum, chemical engineering, mining, coking, municipal engineering, environmental protection, pharmaceutical manufacturing, power generation, shipbuilding, sewage treatment, etc. These are the places where continuous detection of inflammable, explosive, toxic, and harmful gases is essential.

-

1. High-definition display screen: Real-time display of the measured gas concentration.

2. Audible and visual alarm: Over-limit alarm reminder.

3. Three-proof design: Sealing rings are provided at all connection points for water-proof, dust-proof and explosion-proof purposes.

4. Adopting explosion-proof design, it uses sensors with high sensitivity, fast response speed, strong anti-interference ability and stable performance; the detector outputs RS485 signals.

5. The detector is equipped with a passive relay output function; it supports 1000-meter long-distance output and can be connected to various control systems such as DCS and PLC.

6. It is equipped with alarm lights, fault lights and operation lights for indication, allowing you to directly view the current operating status; the product adopts a high-definition dot-matrix LCD screen.

7. Supports adjustment of two groups of alarm values: low alarm and high alarm.

8. Supports infrared remote control operation, allowing remote control operation without opening the cover in a limited space. -

1. Excessive or insufficient oxygen content in the atmosphere may affect the readings of combustible gas sensors.

2. Sudden changes in atmospheric pressure may affect the readings of the sensors.

3. Silicone compound vapors can damage catalytic combustion sensors. Please ensure that such substances do not appear in the usage environment.

4. During use, please keep the sensor's air inlet clean. Blockage of the air inlet may cause the detector's readings to be low or even no response.

5. To ensure the safe and reliable use of the detector, the housing should be reliably grounded. Do not disassemble it by yourself.

6. Do not store this detector in high-temperature, high-humidity or strong static environments.

7. Do not use organic solvents or corrosive liquids (such as alcohol, thinner, etc.) to clean the detector components.

8. Users are not allowed to replace the detector's components by themselves.

9. Operating temperature: Electrochemical -10℃ to +55℃; Catalytic combustion -10℃ to +55℃.

10. Operating humidity: 10 to 95% RH (no condensation).

11. Ensure that the gas flowing into the sensor chamber does not contain moisture, oil stains or other impurities or stains that can easily adhere to the sensor surface and cause sensor failure or damage.

12. It is recommended to calibrate the sensor once every 3 to 6 months, depending on the on-site environment, such as whether there is a large or small amount of target detection gas in the on-site environment.

13. The service life of the sensor is approximately 1 to 3 years, and the specific service life is related to the on-site environmental conditions.

14. Do not plug or unplug the sensor while it is powered on, and do not drop or impact it.

15. Avoid frequent exposure of this product with highly concentrated gas samples whose concentration exceeds the detection range, as this will shorten the sensor's lifespan and even damage the sensor.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation