Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

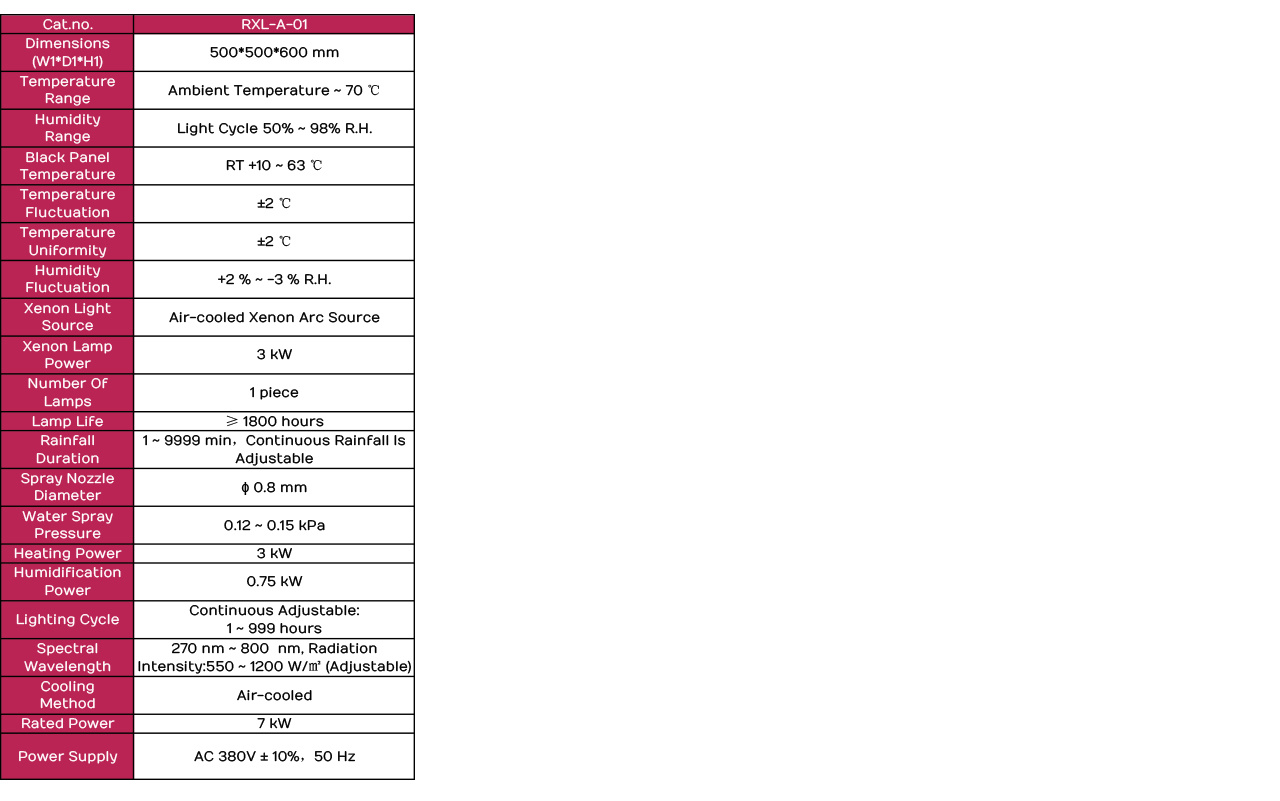

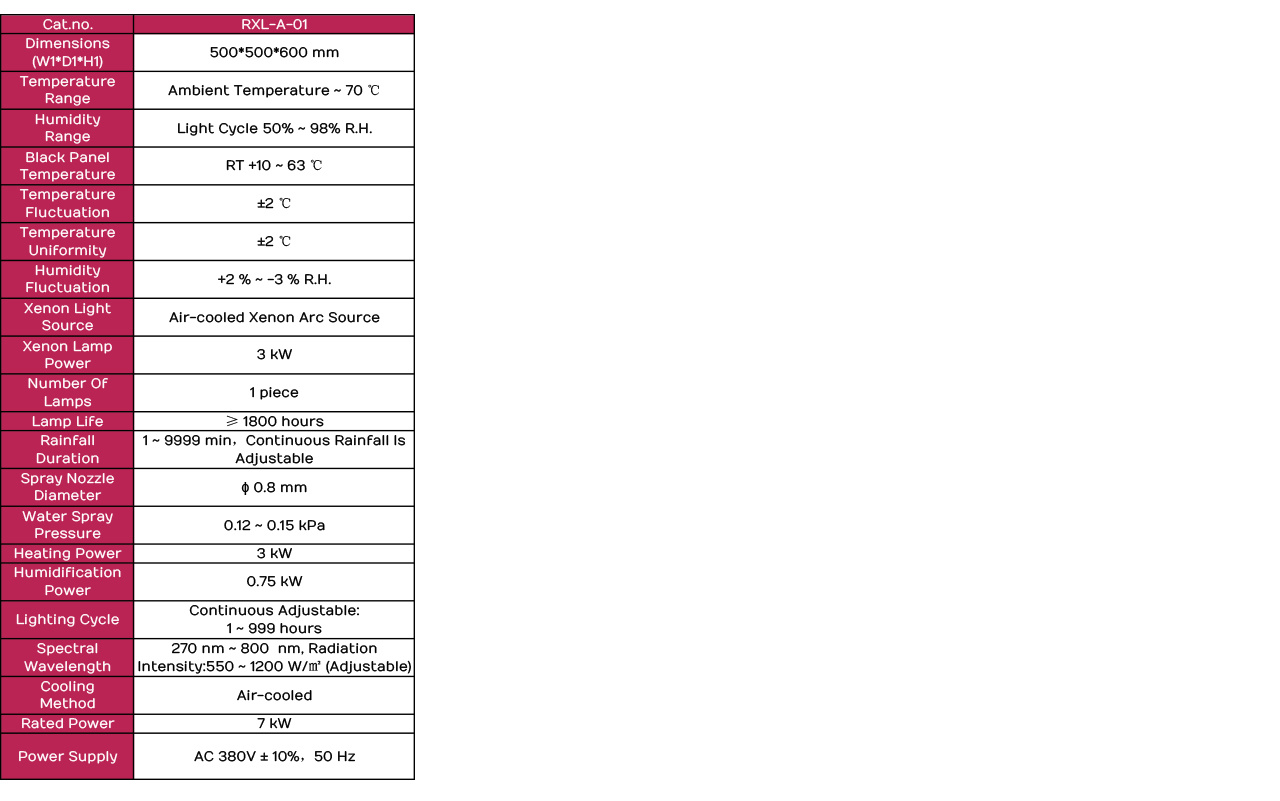

Xenon Lamp Weathering Test Chamber

Xenon Lamp Weathering Test Chamber

RXL-A

Brand:

RUISCI

-

Click to select

- RXL-A-01,±2 ℃

Inventory

180

隐藏域元素占位

Overview

The xenon lamp weathering test chamber accelerates material aging by exposing test specimens to intense xenon arc lamp radiation and thermal effects, evaluating their lightfastness and weather resistance under high-temperature illumination. It is mainly used for automobiles, coatings, rubber, plastics, pigments, adhesives, textiles, etc.

Features

1. The entire chamber shell is made of A3 steel plate with high-temperature spray plastic; the inner wall material of the test chamber is SUS304 high-grade anti-corrosion mirror-finished stainless steel plate.

2. The chamber utilizes high-grade ultra-fine fiberglass insulation between inner and outer walls, providing optimal thermal retention for both heating and cooling applications.

3. The door and door frame are sealed with sealing materials and a unique silicone seal structure, ensuring good sealing performance.

4. The air duct inside the chamber adopts a dual-circulation airflow system, consisting of a long-shaft axial flow fan, a stainless steel multi-wing centrifugal impeller, and a circulation air duct. The top-air-outlet and bottom-air-intake design ensures uniform temperature inside the chamber. This improves the air flow, heating and cooling capacity, and significantly enhances the temperature and humidity uniformity of the test chamber.

5. Black panel temperature: Dual-metal black panel thermometer.

6. Humidification method: External isolated all-stainless steel shallow surface evaporation humidifier.

7. Heating system: Fully independent system, nickel-chromium alloy electric heating element.

8. Water supply system: The humidification water supply is automatically controlled by a water pump.

9. Temperature and humidity circulation system: It uses a high-temperature-resistant and low-noise long-shaft fan motor and stainless steel multi-wing fan blades to achieve strong convection and vertical diffusion circulation.

10. Special nozzles are installed on the top of the working chamber.

11. Irradiance control: The irradiance can be automatically controlled and adjusted by a radiometer to achieve the desired irradiance (more accurate than manual measurement methods because xenon lamps experience measurable intensity decay during test cycles and cannot maintain precise irradiance levels).

12. The current irradiance of the lamp and the cumulative radiation intensity are directly displayed on the panel.

Technical data

1. Grounding protection: The equipment must be reliably grounded to avoid the risk of electrostatic induction or electric leakage.

2. Avoid direct contact: During operation, avoid direct contact with high-temperature components inside the chamber, such as lamps and sample racks, to prevent burns; also, avoid looking directly at the strong light emitted by the xenon lamp to prevent eye damage.

3. Prohibit testing of hazardous substances: Do not test explosive, flammable or highly corrosive substances to avoid danger.

4. Emergency stop: If any abnormal conditions or burnt smell occur during the test, stop the equipment immediately and check it. Cut off the power supply if necessary.

5. Correct door opening and closing: During operation, do not open the chamber door unless necessary, as it may cause injury from high-temperature gas, interrupt the test or affect the accuracy of the results. When taking or placing samples, wear heat-resistant gloves or use tools, and keep the time as short as possible.

6. Stable parameter settings: Do not change the set parameter values randomly when operating the instrument, as it may affect the control accuracy of the equipment and the accuracy of the test results. Avoid frequent adjustment of parameters during the test.

7. Regular inspection of components: Regularly check whether the power cord, terminal posts, water pressure controller, water level in the circulating water chamber, and other components are loose, damaged or abnormal to ensure the normal operation of the equipment.

8. Maintenance and cleaning: Regularly clean the interior of the test chamber, especially the glass and reflectors around the xenon lamp, to avoid dust, oil stains and other contaminants affecting the test results. Use appropriate cleaning agents and tools during cleaning to avoid damaging the equipment.

9. Suitable installation environment: 1. Ambient temperature: 5℃ to +35℃ (average temperature within 24 hours ≤ 35℃), ambient humidity: ≤ 85% R.H. The operating environment should be below 35℃ and well-ventilated. Do not place anything within 80 cm in front, back, left and right of the machine.

10. Water quality requirements: Use deionized water or distilled water as the water supply to ensure stable water pressure. Install an inline particulate filter installed at the inlet to prevent pipe clogging.

keyword:

Xenon Lamp Weathering Test Chamber

Xenon Arc Weathering Tester

Xenon Lamp UV Aging Test Equipment

Paint/Plastic Xenon Weather Resistance Tester

Previous:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Xenon Lamp Weathering Test Chamber

- Subtitle: Xenon Lamp Weathering Test Chamber

- Model: RXL-A

- 全部型号: RXL-A-01,Xenon Lamp Weathering Test Chamber,Xenon Arc Weathering Tester,Xenon Lamp UV Aging Test Equipment,Paint/Plastic Xenon Weather Resistance Tester

The xenon lamp weathering test chamber accelerates material aging by exposing test specimens to intense xenon arc lamp radiation and thermal effects, evaluating their lightfastness and weather resistance under high-temperature illumination.

The xenon lamp weathering test chamber accelerates material aging by exposing test specimens to intense xenon arc lamp radiation and thermal effects, evaluating their lightfastness and weather resistance under high-temperature illumination. It is mainly used for automobiles, coatings, rubber, plastics, pigments, adhesives, textiles, etc.

-

1. The entire chamber shell is made of A3 steel plate with high-temperature spray plastic; the inner wall material of the test chamber is SUS304 high-grade anti-corrosion mirror-finished stainless steel plate.

2. The chamber utilizes high-grade ultra-fine fiberglass insulation between inner and outer walls, providing optimal thermal retention for both heating and cooling applications.

3. The door and door frame are sealed with sealing materials and a unique silicone seal structure, ensuring good sealing performance.

4. The air duct inside the chamber adopts a dual-circulation airflow system, consisting of a long-shaft axial flow fan, a stainless steel multi-wing centrifugal impeller, and a circulation air duct. The top-air-outlet and bottom-air-intake design ensures uniform temperature inside the chamber. This improves the air flow, heating and cooling capacity, and significantly enhances the temperature and humidity uniformity of the test chamber.

5. Black panel temperature: Dual-metal black panel thermometer.

6. Humidification method: External isolated all-stainless steel shallow surface evaporation humidifier.

7. Heating system: Fully independent system, nickel-chromium alloy electric heating element.

8. Water supply system: The humidification water supply is automatically controlled by a water pump.

9. Temperature and humidity circulation system: It uses a high-temperature-resistant and low-noise long-shaft fan motor and stainless steel multi-wing fan blades to achieve strong convection and vertical diffusion circulation.

10. Special nozzles are installed on the top of the working chamber.

11. Irradiance control: The irradiance can be automatically controlled and adjusted by a radiometer to achieve the desired irradiance (more accurate than manual measurement methods because xenon lamps experience measurable intensity decay during test cycles and cannot maintain precise irradiance levels).

12. The current irradiance of the lamp and the cumulative radiation intensity are directly displayed on the panel. -

1. Grounding protection: The equipment must be reliably grounded to avoid the risk of electrostatic induction or electric leakage.

2. Avoid direct contact: During operation, avoid direct contact with high-temperature components inside the chamber, such as lamps and sample racks, to prevent burns; also, avoid looking directly at the strong light emitted by the xenon lamp to prevent eye damage.

3. Prohibit testing of hazardous substances: Do not test explosive, flammable or highly corrosive substances to avoid danger.

4. Emergency stop: If any abnormal conditions or burnt smell occur during the test, stop the equipment immediately and check it. Cut off the power supply if necessary.

5. Correct door opening and closing: During operation, do not open the chamber door unless necessary, as it may cause injury from high-temperature gas, interrupt the test or affect the accuracy of the results. When taking or placing samples, wear heat-resistant gloves or use tools, and keep the time as short as possible.

6. Stable parameter settings: Do not change the set parameter values randomly when operating the instrument, as it may affect the control accuracy of the equipment and the accuracy of the test results. Avoid frequent adjustment of parameters during the test.

7. Regular inspection of components: Regularly check whether the power cord, terminal posts, water pressure controller, water level in the circulating water chamber, and other components are loose, damaged or abnormal to ensure the normal operation of the equipment.

8. Maintenance and cleaning: Regularly clean the interior of the test chamber, especially the glass and reflectors around the xenon lamp, to avoid dust, oil stains and other contaminants affecting the test results. Use appropriate cleaning agents and tools during cleaning to avoid damaging the equipment.

9. Suitable installation environment: 1. Ambient temperature: 5℃ to +35℃ (average temperature within 24 hours ≤ 35℃), ambient humidity: ≤ 85% R.H. The operating environment should be below 35℃ and well-ventilated. Do not place anything within 80 cm in front, back, left and right of the machine.

10. Water quality requirements: Use deionized water or distilled water as the water supply to ensure stable water pressure. Install an inline particulate filter installed at the inlet to prevent pipe clogging.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation