Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Salt Spray Corrosion Testing Chamber

Salt Spray Corrosion Testing Chamber

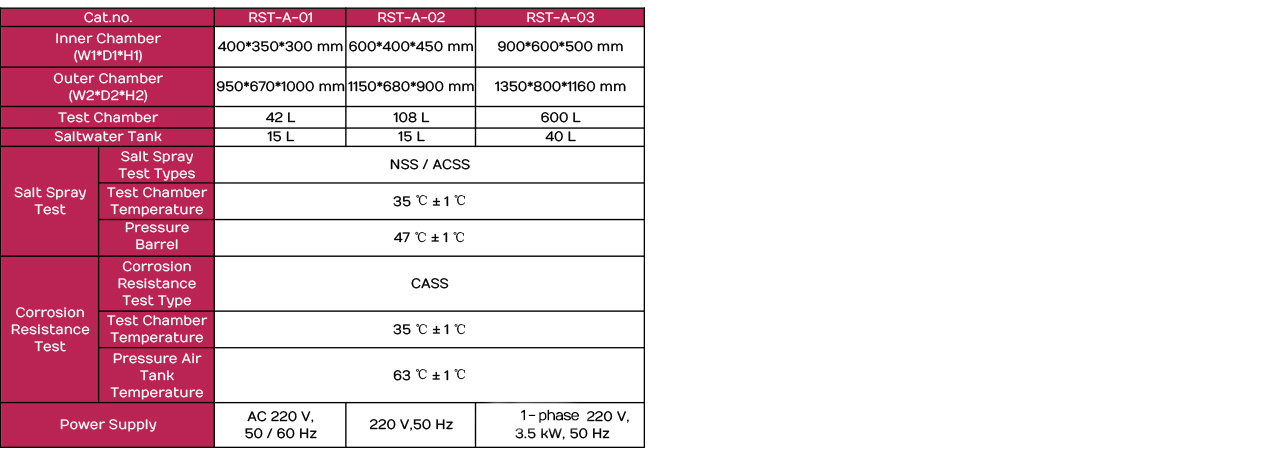

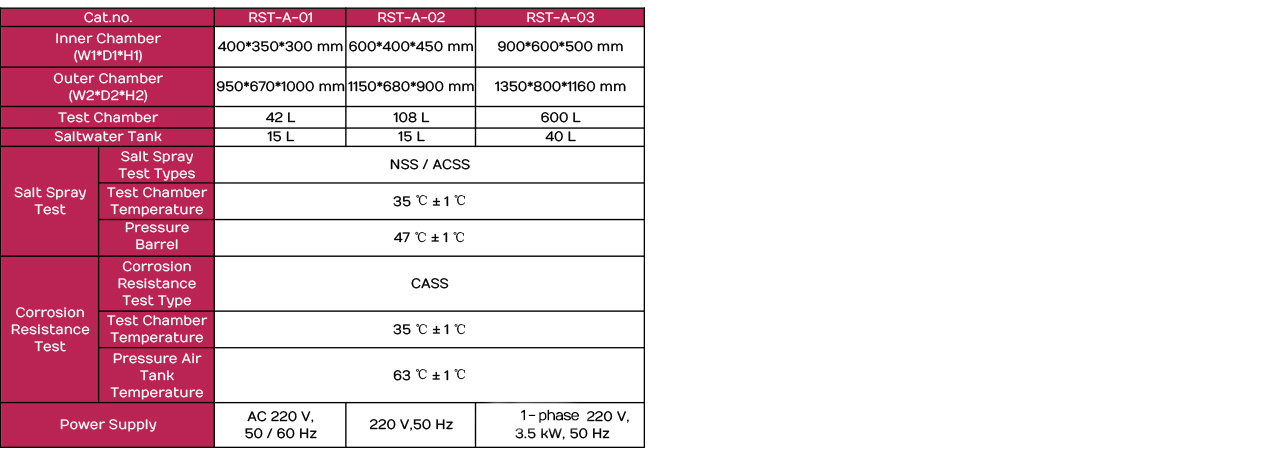

RST-A

Brand:

RUISCI

-

Click to select

- RST-A-01,42L

- RST-A-02,108L

- RST-A-03,600L

Inventory

540

隐藏域元素占位

Overview

The salt spray corrosion test chamber is used to evaluate the corrosion resistance of various material surface treatments, including coatings, electroplating, organic and inorganic films, anodizing, rust-proof oils, and other anti-corrosion processes, thereby ensuring product quality.

Features

1. The test machine's cabinet is made of light gray impact-resistant PVC board with a thickness of 5mm and can withstand temperatures up to 85℃. The edges are reinforced with a 10mm thick layer for added structural strength.

2. The sealing of the test chamber cover is made of PVC impact-resistant board with a thickness of 5mm, which does not distort and deform when used at high temperatures. The edge of the inner and outer double-thickness, to prevent distortion and deformation due to long-term high temperature. The thickness is 15mm.

3. The hidden integrated reagent replenishment bottle is easy to clean and operate.

4. The saturated air tank uses a high-pressure and heat-insulating tank, which provides the best heat insulation effect.

5. The system adopts Bernoulli's principle to draw and atomize saline solution, ensuring uniform mist distribution with zero risk of clogging or crystallization. This ensures continuous testing standards.

6. Heating system: It adopts direct heating method, which has a fast heating speed and reduces standby time. When the temperature reaches the set point, it automatically switches to a constant temperature state. The temperature is precise and power consumption is low. The heating tube is made of pure titanium, which is resistant to acid and alkali corrosion and has an extremely long service life.

7. Standards of use: CNS 3627 3885 4159 7669 8886; JISD-0201; H-8502; H-8610; K-5400; Z-2371.

Technical data

1. When the water level is low, the power supply is automatically cut off and the safety warning light is illuminated to indicate.

2. When the temperature is too high, the power supply to the heater is automatically cut off and the safety warning light is illuminated to indicate.

3. When the water level of the test solution (salt water) is low, the safety warning light is illuminated to indicate and an alarm is triggered.

4. Leakage protection function: It prevents personal injury and instrument malfunction caused by electrical leakage or short circuit.

5. Water supply system: It adopts both automatic and manual water supply systems to maintain proper water levels in the pressure barrel and test chamber, preventing instrument damage caused by overheating due to water shortage.

6. Demisting system: It removes the salt mist in the test chamber during the test process and when the machine is shut down, preventing corrosive gas from flowing out and damaging other precision instruments in the test chamber.

keyword:

Salt Spray Corrosion Testing Chamber

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Salt Spray Corrosion Testing Chamber

- Subtitle: Salt Spray Corrosion Testing Chamber

- Model: RST-A

- 全部型号: RST-A-01,RST-A-02,RST-A-03,Salt Spray Corrosion Testing Chamber

The salt spray corrosion test chamber is used to evaluate the corrosion resistance of various material surface treatments.

The salt spray corrosion test chamber is used to evaluate the corrosion resistance of various material surface treatments, including coatings, electroplating, organic and inorganic films, anodizing, rust-proof oils, and other anti-corrosion processes, thereby ensuring product quality.

-

1. The test machine's cabinet is made of light gray impact-resistant PVC board with a thickness of 5mm and can withstand temperatures up to 85℃. The edges are reinforced with a 10mm thick layer for added structural strength.

2. The sealing of the test chamber cover is made of PVC impact-resistant board with a thickness of 5mm, which does not distort and deform when used at high temperatures. The edge of the inner and outer double-thickness, to prevent distortion and deformation due to long-term high temperature. The thickness is 15mm.

3. The hidden integrated reagent replenishment bottle is easy to clean and operate.

4. The saturated air tank uses a high-pressure and heat-insulating tank, which provides the best heat insulation effect.

5. The system adopts Bernoulli's principle to draw and atomize saline solution, ensuring uniform mist distribution with zero risk of clogging or crystallization. This ensures continuous testing standards.

6. Heating system: It adopts direct heating method, which has a fast heating speed and reduces standby time. When the temperature reaches the set point, it automatically switches to a constant temperature state. The temperature is precise and power consumption is low. The heating tube is made of pure titanium, which is resistant to acid and alkali corrosion and has an extremely long service life.

7. Standards of use: CNS 3627 3885 4159 7669 8886; JISD-0201; H-8502; H-8610; K-5400; Z-2371. -

1. When the water level is low, the power supply is automatically cut off and the safety warning light is illuminated to indicate.

2. When the temperature is too high, the power supply to the heater is automatically cut off and the safety warning light is illuminated to indicate.

3. When the water level of the test solution (salt water) is low, the safety warning light is illuminated to indicate and an alarm is triggered.

4. Leakage protection function: It prevents personal injury and instrument malfunction caused by electrical leakage or short circuit.

5. Water supply system: It adopts both automatic and manual water supply systems to maintain proper water levels in the pressure barrel and test chamber, preventing instrument damage caused by overheating due to water shortage.

6. Demisting system: It removes the salt mist in the test chamber during the test process and when the machine is shut down, preventing corrosive gas from flowing out and damaging other precision instruments in the test chamber.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation