Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Muffle Furnace

Muffle Furnace

RBR-A,RBR-B,RBR-C,RBR-D

Brand:

RUISCI

-

Click to select

- RBR-A-01,2L,Electric Furnace

- RBR-A-02,7L,Electric Furnace

- RBR-A-03,16L,Electric Furnace

- RBR-A-04,30L,Electric Furnace

- RBR-A-05,2L,Nickel Chromium

- RBR-A-06,7L,Nickel Chromium

- RBR-A-07,16L,Nickel Chromium

- RBR-A-08,4L,Nickel Chromium

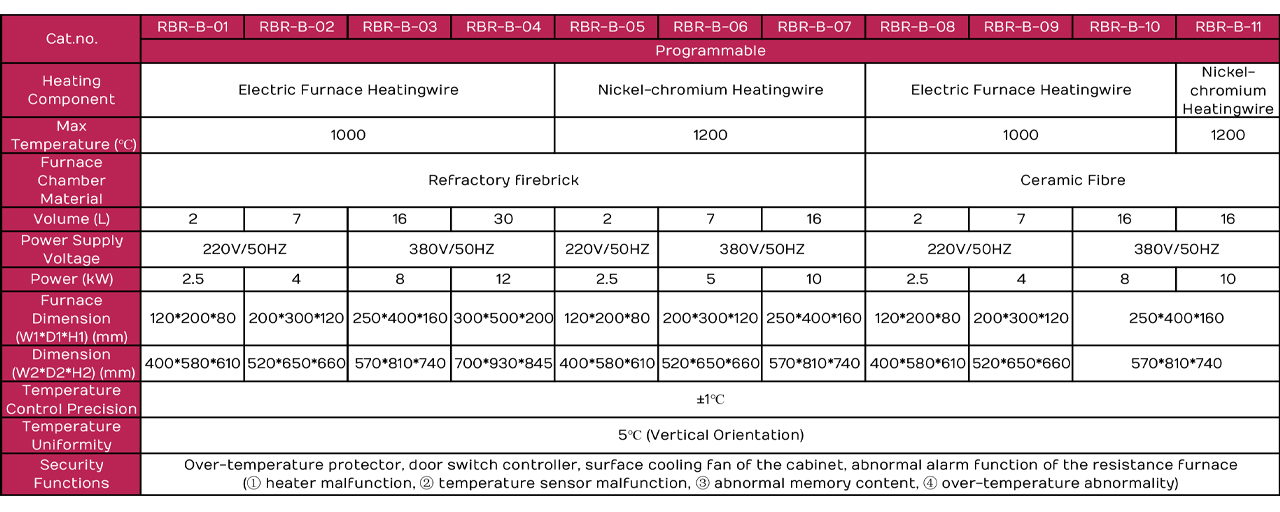

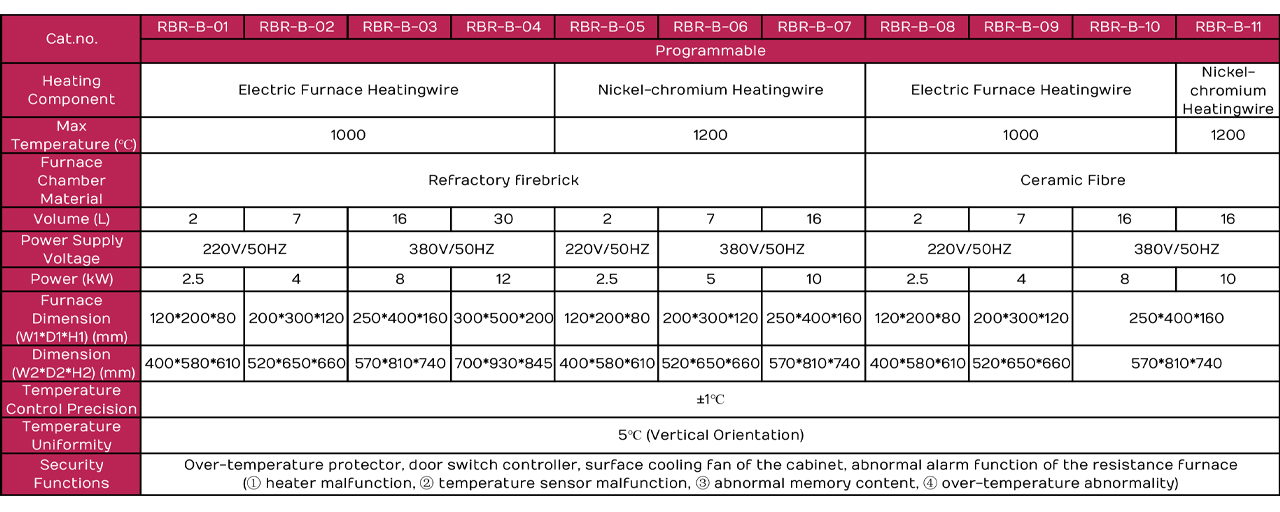

- RBR-B-01,2L,Electric Furnace Heatingwire

- RBR-B-02,7L,Electric Furnace Heatingwire

- RBR-B-03,16L,Electric Furnace Heatingwire

- RBR-B-04,30L,Electric Furnace Heatingwire

- RBR-B-05,2L,Nickel-chromium Heatingwire

- RBR-B-06,7L,Nickel-chromium Heatingwire

- RBR-B-07,16L,Nickel-chromium Heatingwire

- RBR-B-08,2L,Electric Furnace Heatingwire

- RBR-B-09,7L,Electric Furnace Heatingwire

- RBR-B-10,16L,Electric Furnace Heatingwire

- RBR-B-11,16L,Nickel Chromium Heatingwire

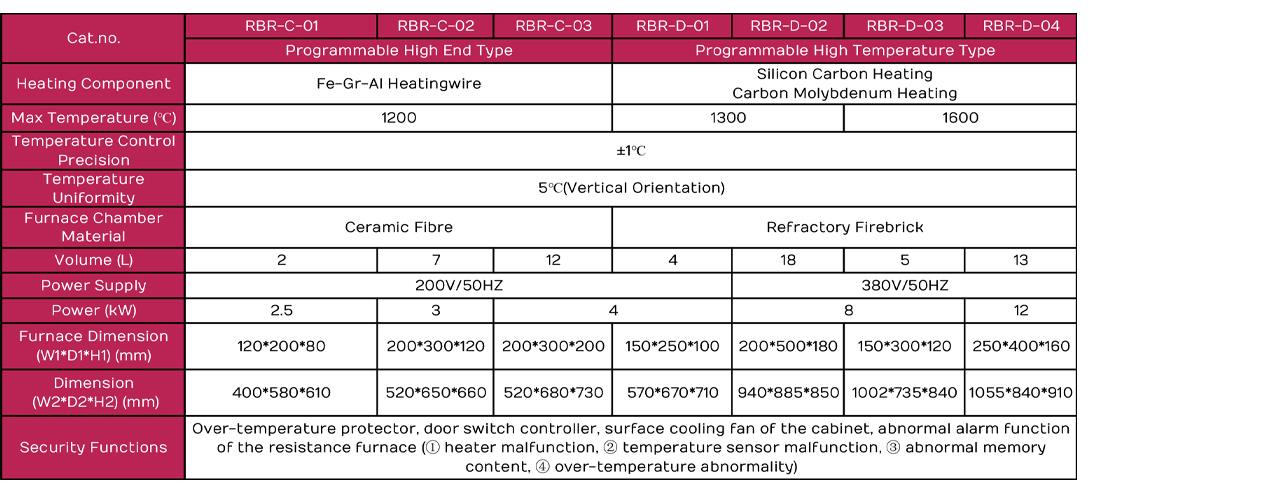

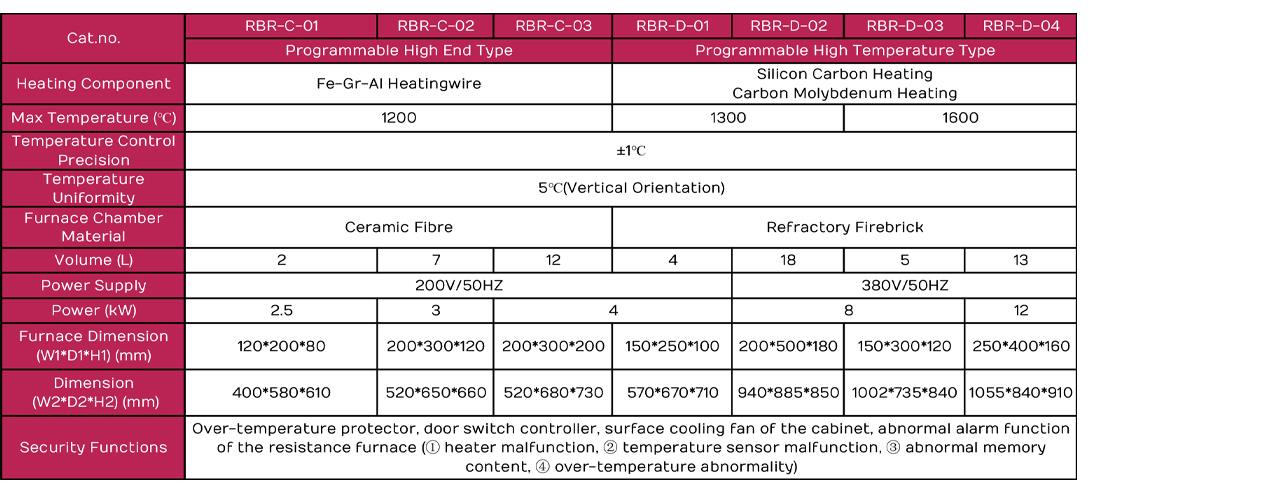

- RBR-C-01,2L,Fe-Gr-Al Heatingwire

- RBR-C-02,7.2L,Fe-Gr-Al Heatingwire

- RBR-C-03,12L,Fe-Gr-Al Heatingwire

- RBR-D-01,4L,Silicon Carbon heating,Carbon Molybdenum heating

- RBR-D-02,18L,Silicon Carbon heating,Carbon Molybdenum heating

- RBR-D-03,5L,Silicon Carbon heating,Carbon Molybdenum heating

- RBR-D-04,13L,Silicon Carbon heating,Carbon Molybdenum heating

Inventory

4576

隐藏域元素占位

Overview

A Muffle Furnace is a box-type experimental equipment that converts electrical energy into thermal energy through the principle of resistance heating, thereby achieving high-temperature heating of workpieces or materials. It is widely used in laboratory research for heating and drying various materials.

Features

1. The PID temperature controller ensures precise temperature control. It features multi-stage programmable control and automatic operation.

2. The distinctive furnace door design offers excellent sealing, preventing the leakage of high-temperature hot gas, ensuring uniform temperature within the furnace chamber and corrosion resistance.

3. Ceramic fiber board is employed as the heat insulation and preservation material, providing superior heat insulation and maintaining a low surface temperature of the box.

4. It is furnished with an over-temperature protector, door switch controller, surface cooling fan of the box, and abnormal alarm function to guarantee safe operation.

5. Multiple heat dissipation holes are provided for rapid heat dissipation without influencing the service life of the main unit.

Technical data

Environmental Conditions:

1. Temperature and Humidity: The working environment temperature should range from 0 to 50°C, the relative humidity should be less than 80%, and the atmospheric pressure should be within 86.0 to 106.0 kPa.

2. Absence of Flammable and Explosive Substances: The equipment should be positioned in a dry and well-ventilated location, free of corrosive gases, flammable substances, and explosive materials.

3. Avoidance of Heat Radiation: The box-type resistance furnace should be maintained at a certain distance from surrounding objects to prevent heat radiation. The clearance from the wall should exceed 200mm.

4. Prevention of Conductive Dust from Entering the Equipment: This is to avoid affecting the normal operation of the electrical system.

Precautions:

1. Select the appropriate temperature range and heating elements in accordance with application requirements.

2. Opt for a suitable temperature control system to guarantee temperature stability and uniformity.

3. The power supply of the box-type resistance furnace and the electrical equipment should be inspected to ensure their normal operation.

4. Since the electric furnace may become damp during storage and transportation, it is necessary to conduct oven drying before use. Dry from room temperature to 200°C for 4 hours, and then from 200°C to 600°C for another 4 hours.

5. Protective gloves should be worn during operation. When loading or unloading samples, it is essential to cut off the power supply first to ensure safety.

6. Consider the dimensions of the furnace chamber and the workpieces. Ensure that the furnace chamber can accommodate the required workpieces and leave sufficient space to guarantee uniform heating.

7. The condition of the heating elements should be inspected regularly, and aged or damaged elements should be replaced promptly to ensure the normal operation of the equipment.

8. The exterior and interior of the furnace body should be cleaned regularly to remove dust, dirt, residues, and oxides, maintaining a clean and tidy state.

9. Relevant safety operation procedures should be followed during operation to avoid high-temperature burns and electrical accidents.

keyword:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Muffle Furnace

- Subtitle: Muffle Furnace

- Model: RBR-A,RBR-B,RBR-C,RBR-D

- 全部型号: RBR-A-01,RBR-A-02,RBR-A-03,RBR-A-04,RBR-A-05,RBR-A-06,RBR-A-07,RBR-A-08,RBR-B-01,RBR-B-02,RBR-B-03,RBR-B-04,RBR-B-05,RBR-B-06,RBR-B-07,RBR-B-08,RBR-B-09,RBR-B-10,RBR-B-11,RBR-C-01,RBR-C-02,RBR-C-03,RBR-D-01,RBR-D-02,RBR-D-03,RBR-D-04

A Muffle Furnace is a box-type experimental equipment that converts electrical energy into thermal energy through the principle of resistance heating, thereby achieving high-temperature heating of workpieces or materials.

A Muffle Furnace is a box-type experimental equipment that converts electrical energy into thermal energy through the principle of resistance heating, thereby achieving high-temperature heating of workpieces or materials. It is widely used in laboratory research for heating and drying various materials.

-

1. The PID temperature controller ensures precise temperature control. It features multi-stage programmable control and automatic operation.

2. The distinctive furnace door design offers excellent sealing, preventing the leakage of high-temperature hot gas, ensuring uniform temperature within the furnace chamber and corrosion resistance.

3. Ceramic fiber board is employed as the heat insulation and preservation material, providing superior heat insulation and maintaining a low surface temperature of the box.

4. It is furnished with an over-temperature protector, door switch controller, surface cooling fan of the box, and abnormal alarm function to guarantee safe operation.

5. Multiple heat dissipation holes are provided for rapid heat dissipation without influencing the service life of the main unit. -

Environmental Conditions:

1. Temperature and Humidity: The working environment temperature should range from 0 to 50°C, the relative humidity should be less than 80%, and the atmospheric pressure should be within 86.0 to 106.0 kPa.

2. Absence of Flammable and Explosive Substances: The equipment should be positioned in a dry and well-ventilated location, free of corrosive gases, flammable substances, and explosive materials.

3. Avoidance of Heat Radiation: The box-type resistance furnace should be maintained at a certain distance from surrounding objects to prevent heat radiation. The clearance from the wall should exceed 200mm.

4. Prevention of Conductive Dust from Entering the Equipment: This is to avoid affecting the normal operation of the electrical system.Precautions:

1. Select the appropriate temperature range and heating elements in accordance with application requirements.

2. Opt for a suitable temperature control system to guarantee temperature stability and uniformity.

3. The power supply of the box-type resistance furnace and the electrical equipment should be inspected to ensure their normal operation.

4. Since the electric furnace may become damp during storage and transportation, it is necessary to conduct oven drying before use. Dry from room temperature to 200°C for 4 hours, and then from 200°C to 600°C for another 4 hours.

5. Protective gloves should be worn during operation. When loading or unloading samples, it is essential to cut off the power supply first to ensure safety.

6. Consider the dimensions of the furnace chamber and the workpieces. Ensure that the furnace chamber can accommodate the required workpieces and leave sufficient space to guarantee uniform heating.

7. The condition of the heating elements should be inspected regularly, and aged or damaged elements should be replaced promptly to ensure the normal operation of the equipment.

8. The exterior and interior of the furnace body should be cleaned regularly to remove dust, dirt, residues, and oxides, maintaining a clean and tidy state.

9. Relevant safety operation procedures should be followed during operation to avoid high-temperature burns and electrical accidents.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation