Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

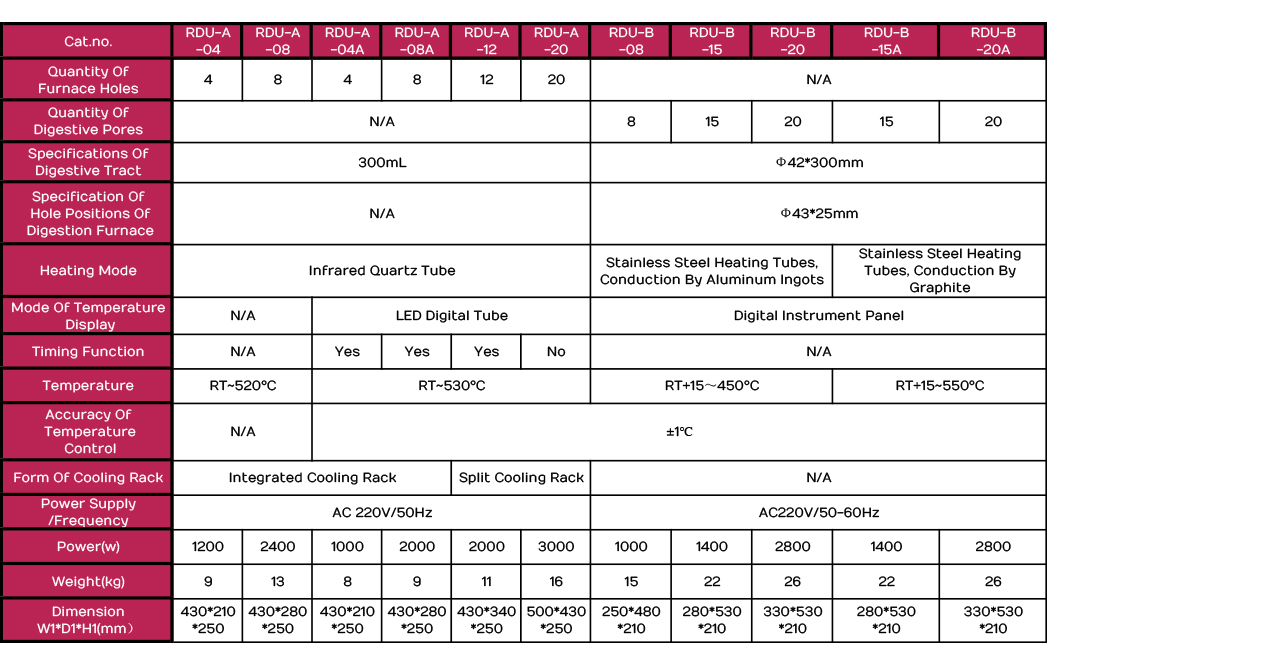

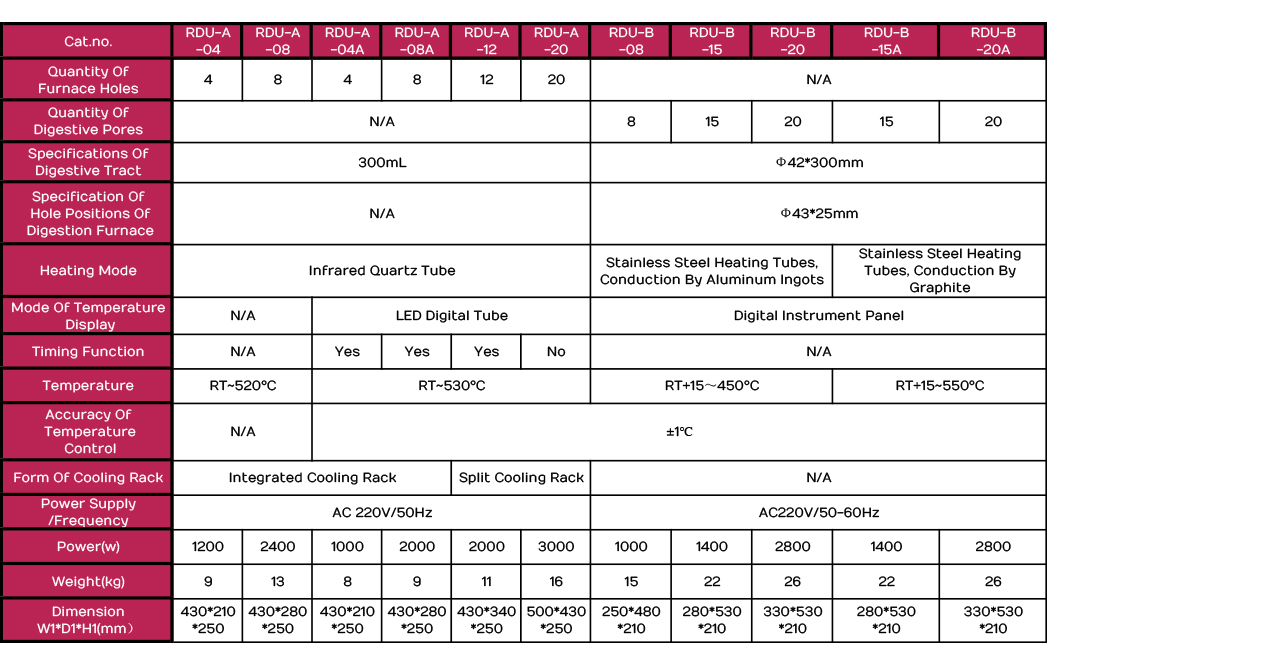

Kjeldahl Digestion Stove

Kjeldahl Digestion Stove

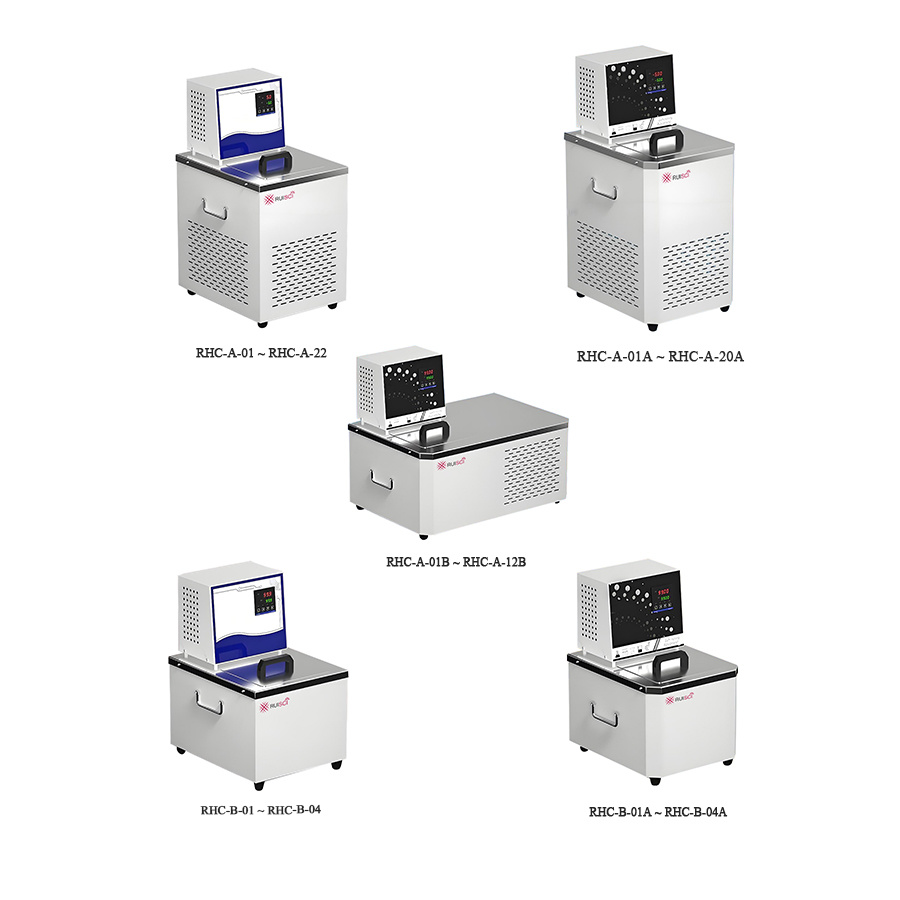

RDU-A,RDU-B

Brand:

RUISCI

-

Click to select

- RDU-A-04,Infrared Quartz Tube

- RDU-A-08,Infrared Quartz Tube

- RDU-A-04A,Infrared Quartz Tube,LED Digital Tube

- RDU-A-08A,Infrared Quartz Tube,LED Digital Tube

- RDU-A-12,Infrared Quartz Tube,LED Digital Tube

- RDU-A-20,Infrared Quartz Tube,LED Digital Tube

- RDU-B-08,Stainless Steel Heating Tubes

- RDU-B-15,Stainless SteStainless Steel Heating Tubes

- RDU-B-20,Stainless Steel Heating Tubes

- RDU-B-15A,Stainless Steel Heating Tubes

- RDU-B-20A,Stainless Steel Heating Tubes

Inventory

2178

隐藏域元素占位

Overview

The Kjeldahl Digestion Stove is a piece of equipment employed in laboratories for the pre-treatment of samples in the Kjeldahl nitrogen determination method and is used in combination with a distiller. It adopts a well-type electric heating configuration and is furnished with Infrared Quartz Tube or Stainless Steel Heating Tubes for heating, which can rapidly elevate the temperature and improve the digestion efficiency. The Kjeldahl Digestion Stove is outfitted with an exhaust collection tube, through which waste gas is extracted and discharged by water flow pumping.

Features

1. Highly efficient digestion: The Infrared Quartz Tube heating structure exhibits superior heating performance, a high thermal effect conversion rate, and resistance to acids and alkalis. Each heating element is independently controlled by a switch.

2. Excellent sealing: The connection between the collection tube and the digestion tube is completely sealed with a corrosion-resistant fluorine rubber ring, ensuring enhanced safety during usage.

3. Integrated heating of aluminum ingot/graphite: Heating within the furnace core attains an optimal thermal effect, expedites the digestion process, and reduces temperature variations within the core, resulting in uniform sample digestion.

4. Stainless steel heating tubes: In a well-shaped structure, they offer a large heating area. Heating with stainless steel heating tubes and the conduction of heat by aluminum ingot/graphite feature a high conversion rate of thermal effect and resistance to acids and alkalis.

5. Stainless steel countertop: It demonstrates good corrosion resistance.

6. Optimized treatment of the furnace chamber: Even in a long-term high-temperature environment, there will be no phenomena such as powder shedding, grain loss, or damage due to oxidation.

7. Heat dissipation isolation: It mitigates the influence of high-temperature radiation from the furnace body on the control system.

Technical data

Working Environment Conditions:

1. Temperature: 0 - 40°C.

2. Relative Humidity: ≤ 80%.

3. Power Supply: Voltage 220V. For the Infrared Quartz Tube heating mode, the frequency is 50Hz; for the Stainless Steel Heating Tube heating mode, the frequency is 50 - 60Hz.

4. Ventilation: It is mandatory to be utilized in a well-ventilated setting, optimally within a fume hood, to prevent the escape of harmful gases.

5. Water Supply and Drainage: Guarantee smooth water supply and drainage in the laboratory. The placement of the instrument should be within 1.5 meters from the water source.

6. Waste Gas Treatment: It is advisable to be equipped with a waste gas neutralization device or an exhaust system connected to the fume hood for handling the acidic gases generated during digestion.

Precautions:

1. Sample Processing: During digestion, the temperature should be increased gradually to prevent sample overflow or nitrogen loss. For high-fat and high-sugar samples, the digestion time needs to be prolonged.

2. Safety Protection: Operators must don protective gear and monitor the reaction process throughout.

3. Equipment Maintenance: Residues should be promptly cleaned after usage. Regularly inspect the temperature control, pressure control systems, and sealing components.

4. Cooling and Shutdown: After digestion is accomplished, it is necessary to cool down to room temperature. The water source must not be turned off during the cooling stage to ensure the complete exhaustion of waste gas.

5. Emergency Situations: In the event of leakage or fire, the power supply should be immediately cut off and emergency measures adopted.

keyword:

Kjeldahl Digestion Apparatus

Kjeldahl digestion furnace

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Kjeldahl Digestion Stove

- Subtitle: Kjeldahl Digestion Stove

- Model: RDU-A,RDU-B

- 全部型号: Kjeldahl Digestion Apparatus,Kjeldahl digestion furnace,RDU-A-04,RDU-A-08,RDU-A-04A,RDU-A-08A,RDU-A-12,RDU-A-20,RDU-B-08,RDU-B-15,RDU-B-20,RDU-B-15A,RDU-B-20A

The Kjeldahl Digestion Stove is a piece of equipment employed in laboratories for the pre-treatment of samples in the Kjeldahl nitrogen determination method and is used in combination with a distiller.

The Kjeldahl Digestion Stove is a piece of equipment employed in laboratories for the pre-treatment of samples in the Kjeldahl nitrogen determination method and is used in combination with a distiller. It adopts a well-type electric heating configuration and is furnished with Infrared Quartz Tube or Stainless Steel Heating Tubes for heating, which can rapidly elevate the temperature and improve the digestion efficiency. The Kjeldahl Digestion Stove is outfitted with an exhaust collection tube, through which waste gas is extracted and discharged by water flow pumping.

-

1. Highly efficient digestion: The Infrared Quartz Tube heating structure exhibits superior heating performance, a high thermal effect conversion rate, and resistance to acids and alkalis. Each heating element is independently controlled by a switch.

2. Excellent sealing: The connection between the collection tube and the digestion tube is completely sealed with a corrosion-resistant fluorine rubber ring, ensuring enhanced safety during usage.

3. Integrated heating of aluminum ingot/graphite: Heating within the furnace core attains an optimal thermal effect, expedites the digestion process, and reduces temperature variations within the core, resulting in uniform sample digestion.

4. Stainless steel heating tubes: In a well-shaped structure, they offer a large heating area. Heating with stainless steel heating tubes and the conduction of heat by aluminum ingot/graphite feature a high conversion rate of thermal effect and resistance to acids and alkalis.

5. Stainless steel countertop: It demonstrates good corrosion resistance.

6. Optimized treatment of the furnace chamber: Even in a long-term high-temperature environment, there will be no phenomena such as powder shedding, grain loss, or damage due to oxidation.

7. Heat dissipation isolation: It mitigates the influence of high-temperature radiation from the furnace body on the control system. -

Working Environment Conditions:

1. Temperature: 0 - 40°C.

2. Relative Humidity: ≤ 80%.

3. Power Supply: Voltage 220V. For the Infrared Quartz Tube heating mode, the frequency is 50Hz; for the Stainless Steel Heating Tube heating mode, the frequency is 50 - 60Hz.

4. Ventilation: It is mandatory to be utilized in a well-ventilated setting, optimally within a fume hood, to prevent the escape of harmful gases.

5. Water Supply and Drainage: Guarantee smooth water supply and drainage in the laboratory. The placement of the instrument should be within 1.5 meters from the water source.

6. Waste Gas Treatment: It is advisable to be equipped with a waste gas neutralization device or an exhaust system connected to the fume hood for handling the acidic gases generated during digestion.Precautions:

1. Sample Processing: During digestion, the temperature should be increased gradually to prevent sample overflow or nitrogen loss. For high-fat and high-sugar samples, the digestion time needs to be prolonged.

2. Safety Protection: Operators must don protective gear and monitor the reaction process throughout.

3. Equipment Maintenance: Residues should be promptly cleaned after usage. Regularly inspect the temperature control, pressure control systems, and sealing components.

4. Cooling and Shutdown: After digestion is accomplished, it is necessary to cool down to room temperature. The water source must not be turned off during the cooling stage to ensure the complete exhaustion of waste gas.

5. Emergency Situations: In the event of leakage or fire, the power supply should be immediately cut off and emergency measures adopted.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation