Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Impact Sample Notcher

Impact Sample Notcher

RCE-C

Brand:

RUISCI

-

Click to select

- RCE-C-01,Hand Movement

- RCE-C-02,Electric

- RCE-C-03,Fully Automatic

Inventory

723

隐藏域元素占位

Overview

The Impact Sample Notcher is the equipment for fabricating notched specimens when conducting impact toughness tests of non-metallic materials using the Cantilever Beam and Simply Supported Beam Charpy Impact Testers. It is categorized into Hand Movement, Electric, and Fully Automatic types. It can be employed in laboratories for the production of notched specimens.

Features

1. Electric: The direction of feeding is manually controlled by the directional wheel on the right side of the machine body.

2. Fully Automatic: The feeding process is fully automatic, and the notches can be fabricated with just one click.

3. Multi-functional: It supports various types of samples and notches.

4. The cutting tool can be repeatedly ground and enjoys a long service life.

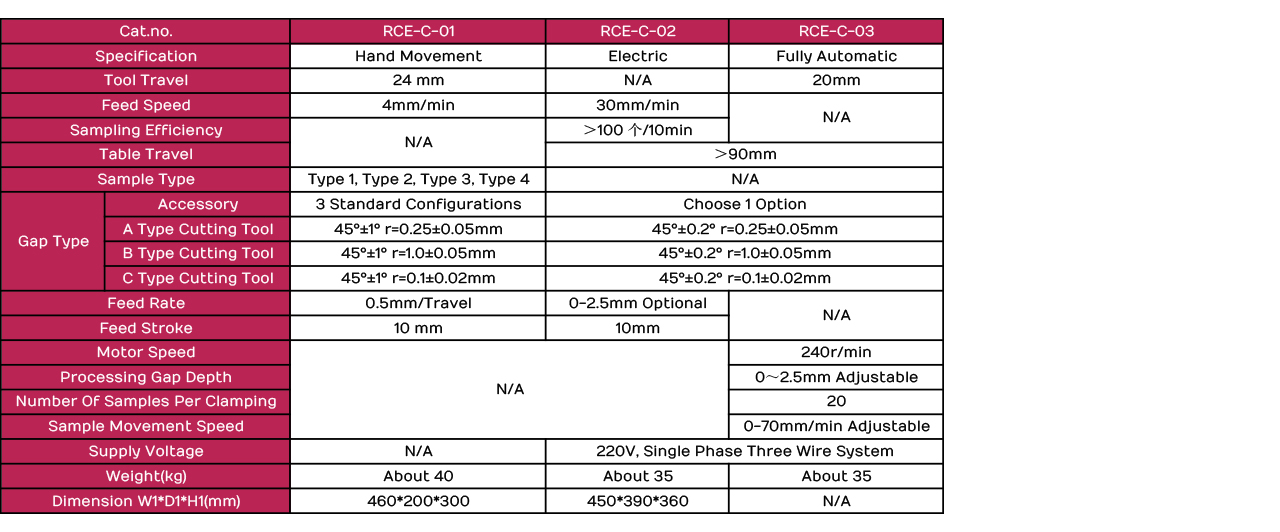

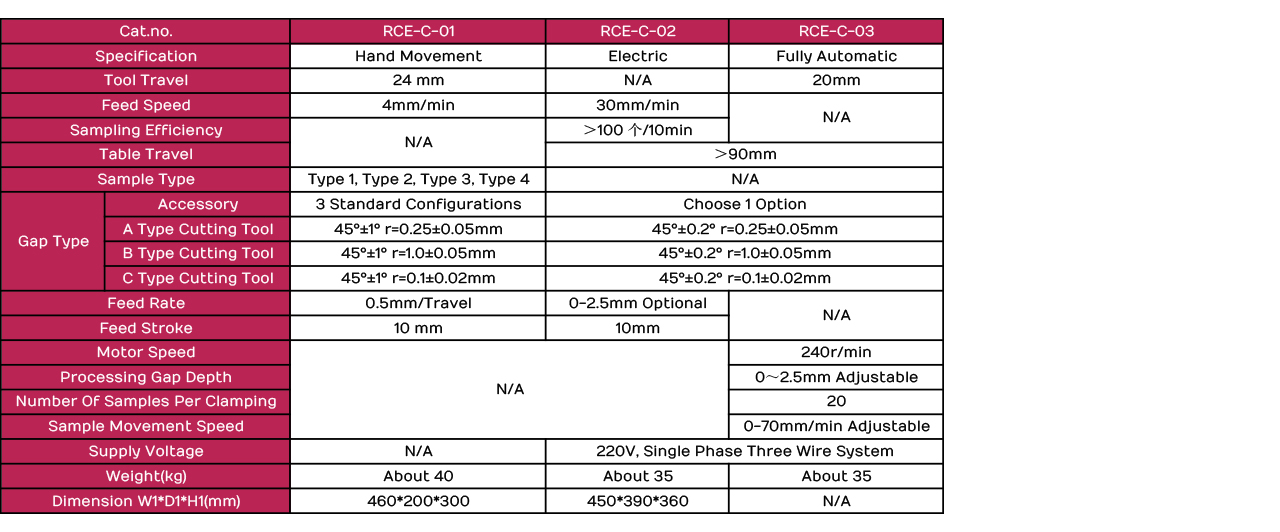

Technical data

Working Environment Conditions:

1. Temperature: 16°C - 26°C.

2. Humidity: 30% - 65%.

3. The laboratory should be well-ventilated, with no dust and harmful gases.

4. It should be placed on a stable workbench, with operation and maintenance space around.

Precautions:

1. Pre-startup Inspection: Inspect whether the appearance of the equipment is intact, whether each component is loose or damaged, and whether the power cord is damaged.

2. Tool Inspection: Ensure that the tool is firmly installed, with a sharp cutting edge and no nicks or abrasions. Regularly inspect the wear of the tool and replace it promptly when necessary.

3. Safety Protection: Wear protective gloves and goggles during operation to avoid injuries caused by tool cutting or debris splashing.

4. Sample Placement: Firmly clamp the sample to ensure its accurate position and prevent loosening or displacement.

5. Equipment Cleaning: Clean the tool and the workbench in a timely manner after use to remove residual sample debris and dust.

6. Avoid Dampness: The equipment should be placed in a dry and well-ventilated environment to avoid dampness or corrosion.

7. Stay Away from Vibration Sources: Avoid placing it in areas with significant vibration to avoid affecting the sample preparation accuracy.

8. Tool Replacement: When replacing the tool, ensure that the equipment is powered off and operate in accordance with the correct methods.

Reference Standard:

ISO180-2000《Plastics — Determination of Izod impact strength》

GB/T1843-2008《Plastics — Determination of Izod impact strength》

JB/T8761-1998《Izod impact testingmachines for plastics》

ASTM D256-2010《Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics》

ISO179-2000《Plastics — Determination of charpy impact properties》

GB/T1043-2008《Plastics — Determination of charpy impact properties》

JB/T8762-1998《Charpy impact testingmachines for plastics》

keyword:

For Impact Tester

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Impact Sample Notcher

- Subtitle: Impact Sample Notcher

- Model: RCE-C

- 全部型号: For Impact Tester,RCE-C-01,RCE-C-02,RCE-C-03

The Impact Sample Notcher is the equipment for fabricating notched specimens when conducting impact toughness tests of non-metallic materials using the Cantilever Beam and Simply Supported Beam Charpy Impact Testers.

The Impact Sample Notcher is the equipment for fabricating notched specimens when conducting impact toughness tests of non-metallic materials using the Cantilever Beam and Simply Supported Beam Charpy Impact Testers. It is categorized into Hand Movement, Electric, and Fully Automatic types. It can be employed in laboratories for the production of notched specimens.

-

1. Electric: The direction of feeding is manually controlled by the directional wheel on the right side of the machine body.

2. Fully Automatic: The feeding process is fully automatic, and the notches can be fabricated with just one click.

3. Multi-functional: It supports various types of samples and notches.

4. The cutting tool can be repeatedly ground and enjoys a long service life. -

Working Environment Conditions:

1. Temperature: 16°C - 26°C.

2. Humidity: 30% - 65%.

3. The laboratory should be well-ventilated, with no dust and harmful gases.

4. It should be placed on a stable workbench, with operation and maintenance space around.Precautions:

1. Pre-startup Inspection: Inspect whether the appearance of the equipment is intact, whether each component is loose or damaged, and whether the power cord is damaged.

2. Tool Inspection: Ensure that the tool is firmly installed, with a sharp cutting edge and no nicks or abrasions. Regularly inspect the wear of the tool and replace it promptly when necessary.

3. Safety Protection: Wear protective gloves and goggles during operation to avoid injuries caused by tool cutting or debris splashing.

4. Sample Placement: Firmly clamp the sample to ensure its accurate position and prevent loosening or displacement.

5. Equipment Cleaning: Clean the tool and the workbench in a timely manner after use to remove residual sample debris and dust.

6. Avoid Dampness: The equipment should be placed in a dry and well-ventilated environment to avoid dampness or corrosion.

7. Stay Away from Vibration Sources: Avoid placing it in areas with significant vibration to avoid affecting the sample preparation accuracy.

8. Tool Replacement: When replacing the tool, ensure that the equipment is powered off and operate in accordance with the correct methods.Reference Standard:

ISO180-2000《Plastics — Determination of Izod impact strength》

GB/T1843-2008《Plastics — Determination of Izod impact strength》

JB/T8761-1998《Izod impact testingmachines for plastics》

ASTM D256-2010《Standard Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics》

ISO179-2000《Plastics — Determination of charpy impact properties》

GB/T1043-2008《Plastics — Determination of charpy impact properties》

JB/T8762-1998《Charpy impact testingmachines for plastics》

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation