Quality Assured

Just Buy It

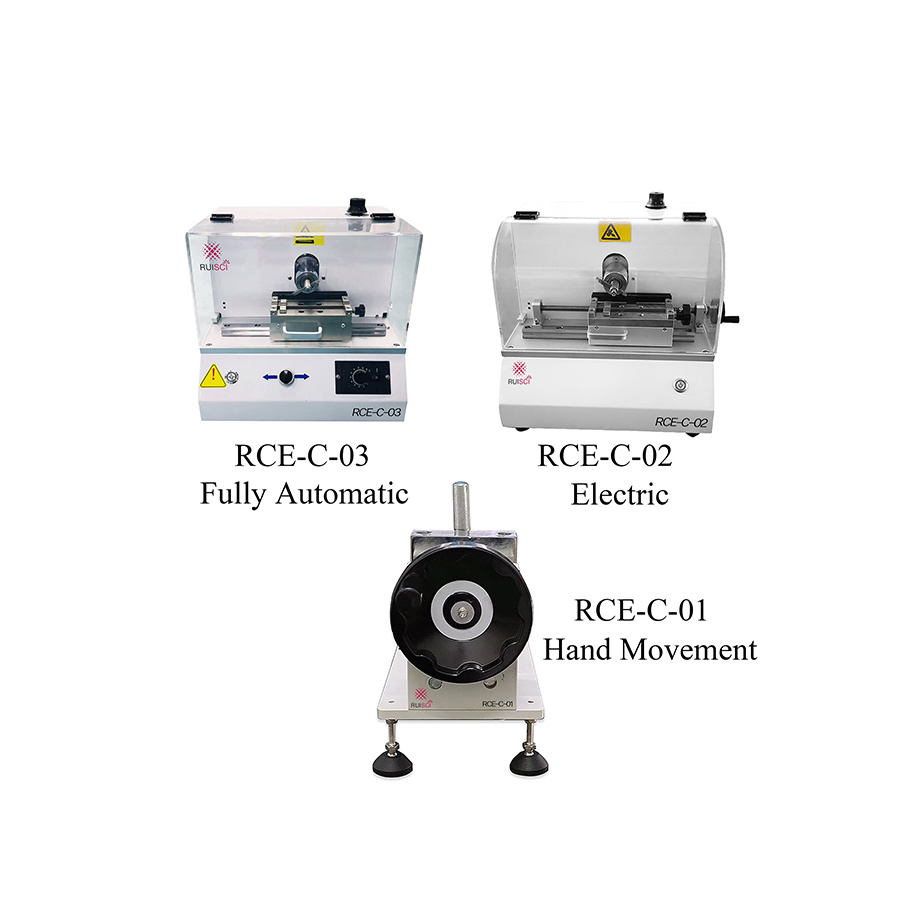

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Ultrasonic Thickness Gauge

Ultrasonic Thickness Gauge

RUTG-A

Brand:

RUISCI

-

Click to select

- RUTG-A-01,1-320mm

- RUTG-A-02,0.8-350mm,0.01mm

- RUTG-A-03,0.8-350mm,0.001mm

- RUTG-A-04,0.6-600mm

Inventory

672

隐藏域元素占位

Overview

Ultrasonic thickness gauge is an instrument that measures material thickness using the ultrasonic pulse-echo principle. It enables non-destructive testing of various materials and complex structures, playing a vital role in industrial production and scientific research.

Features

1. Capable of storing 999 sets of measurement results and saving 18 sets of sound velocities. The maximum, minimum, and average values can be retrieved and analyzed.

2. Characterized by low power consumption, eliminating the need for frequent battery replacement.

3. Features a coating - penetration measurement mode. This enables accurate measurement of the thickness of the substrate beneath the coating without the necessity of removing the coating on the workpiece surface.

4. The device features built-in sonic velocities for 19 common materials, thus enhancing the efficiency of testing procedures.

5. Adopts the QC (Quality Control) measurement mode, which allows for a rapid determination of whether the material thickness meets the specified standards.

6. Utilizes a high - sensitivity dual - crystal probe. This probe effectively reduces clutter signals. The probe housing is fabricated from stainless steel, ensuring robustness and long - lasting performance.

7. Integrates a professional timing chip with a precision of 0.000001 milliseconds. This chip accurately calculates the propagation time of ultrasonic pulses within the measured material, resulting in highly precise data.

8. Can automatically select an appropriate multiple of the ultrasonic signal based on the material type and thickness.

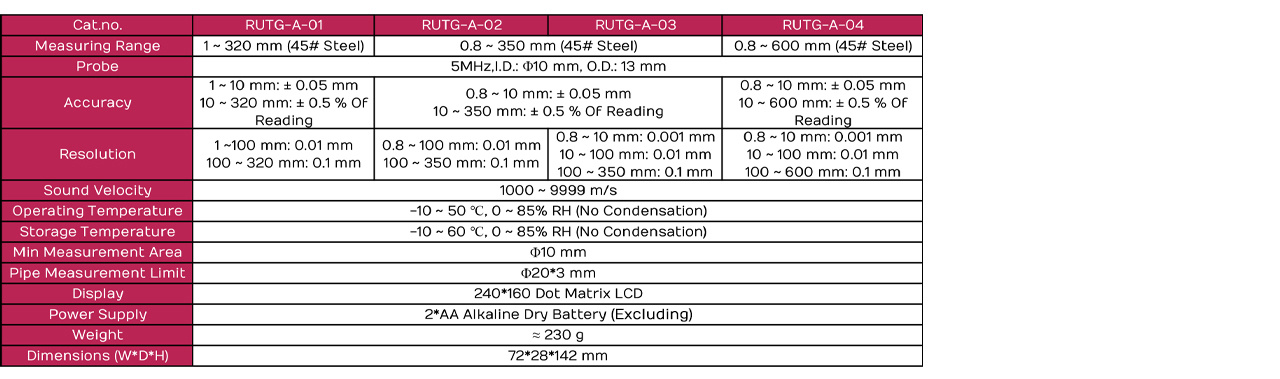

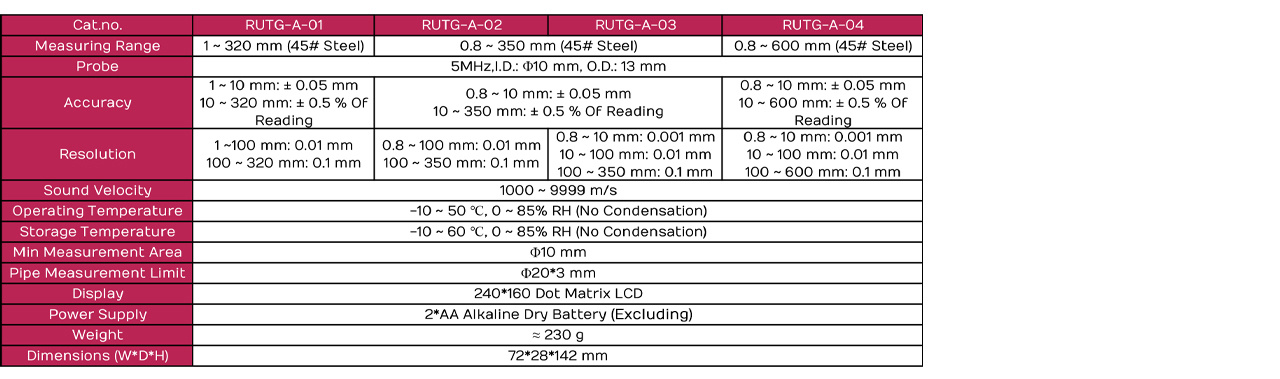

Technical data

Precautions

1. The sound velocity is a crucial parameter in ultrasonic thickness measurement. Only by setting the accurate sound velocity can valid thickness values be acquired. It is advisable to utilize a material with a known thickness and of the same type as the specimen to be measured for setting the sound velocity.

2. The probe should be positioned precisely at the center of the measurement point. Ensure that the outer periphery of the probe does not protrude beyond measured surface.

3. The opposite surface of the measured material must be parallel or coaxial to the measured surface.

4. During the measurement of curved surfaces, align the probe's split surface perpendicular to the curvature axis during measurement.

5. For coarse - grained materials such as cast iron that cause significant ultrasonic scattering . Thus, a coarse - grained probe is required for measurement. Since the probe is vulnerable to scratching on rough surfaces, minimize the sliding of the probe on such surfaces. If the probe is severely worn, it should be replaced promptly.

6. When the instrument operates for an extended period, it is recommended to conduct a reference calibration to mitigate the influence of the external environment on the instrument.

7. When the instrument displays "Low battery", the battery should be replaced with a new one.

8. After using the instrument, clean the probe and the standard test block to prevent corrosion of both the probe and the standard test block.

keyword:

Ultrasonic Thickness Gauge

Ultrasonic Thickness Measuring instrument

Digital Thickness Meter

Precision Ultrasonic Tester

Multi-Material Thickness Tester

Mul-ti Mode Ultrasonic Thickness Gauge

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Ultrasonic Thickness Gauge

- Subtitle: Ultrasonic Thickness Gauge

- Model: RUTG-A

- 全部型号: RUTG-A-01,RUTG-A-02,RUTG-A-03,RUTG-A-04,Ultrasonic Thickness Gauge, Ultrasonic Thickness Measuring instrument,Digital Thickness Meter,Precision Ultrasonic Tester,Multi-Material Thickness Tester,Mul-ti Mode Ultrasonic Thickness Gauge

Ultrasonic thickness gauge is an instrument that measures material thickness using the ultrasonic pulse-echo principle.

Ultrasonic thickness gauge is an instrument that measures material thickness using the ultrasonic pulse-echo principle. It enables non-destructive testing of various materials and complex structures, playing a vital role in industrial production and scientific research.

-

1. Capable of storing 999 sets of measurement results and saving 18 sets of sound velocities. The maximum, minimum, and average values can be retrieved and analyzed.

2. Characterized by low power consumption, eliminating the need for frequent battery replacement.

3. Features a coating - penetration measurement mode. This enables accurate measurement of the thickness of the substrate beneath the coating without the necessity of removing the coating on the workpiece surface.

4. The device features built-in sonic velocities for 19 common materials, thus enhancing the efficiency of testing procedures.

5. Adopts the QC (Quality Control) measurement mode, which allows for a rapid determination of whether the material thickness meets the specified standards.

6. Utilizes a high - sensitivity dual - crystal probe. This probe effectively reduces clutter signals. The probe housing is fabricated from stainless steel, ensuring robustness and long - lasting performance.

7. Integrates a professional timing chip with a precision of 0.000001 milliseconds. This chip accurately calculates the propagation time of ultrasonic pulses within the measured material, resulting in highly precise data.

8. Can automatically select an appropriate multiple of the ultrasonic signal based on the material type and thickness. -

Precautions

1. The sound velocity is a crucial parameter in ultrasonic thickness measurement. Only by setting the accurate sound velocity can valid thickness values be acquired. It is advisable to utilize a material with a known thickness and of the same type as the specimen to be measured for setting the sound velocity.

2. The probe should be positioned precisely at the center of the measurement point. Ensure that the outer periphery of the probe does not protrude beyond measured surface.

3. The opposite surface of the measured material must be parallel or coaxial to the measured surface.

4. During the measurement of curved surfaces, align the probe's split surface perpendicular to the curvature axis during measurement.

5. For coarse - grained materials such as cast iron that cause significant ultrasonic scattering . Thus, a coarse - grained probe is required for measurement. Since the probe is vulnerable to scratching on rough surfaces, minimize the sliding of the probe on such surfaces. If the probe is severely worn, it should be replaced promptly.

6. When the instrument operates for an extended period, it is recommended to conduct a reference calibration to mitigate the influence of the external environment on the instrument.

7. When the instrument displays "Low battery", the battery should be replaced with a new one.

8. After using the instrument, clean the probe and the standard test block to prevent corrosion of both the probe and the standard test block.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation