Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Thermal Analyzer

Thermal Analyzer

RTA-A,RTA-B,RTA-C

Brand:

RUISCI

-

Click to select

- RTA-A-01,Thermogravimetric

- RTA-A-02,Thermogravimetric

- RTA-B-01,Simultaneous Thermal

- RTA-B-02,Simultaneous Thermal

- RTA-C-01,High-Temperature Differential Scanning Calorimeter

Inventory

840

隐藏域元素占位

Overview

Thermal analyzer is an apparatus employed to investigate the thermal and mechanical properties of materials. It is capable of analyzing parameters such as the phase transition temperature and thermal stability of materials. This instrument finds extensive applications in the fields of materials science, chemistry, physics, and engineering.

Features

1. An ARM processor is adopted, enabling faster sampling and processing speeds.

2. A 7-inch full-color 24-bit touch screen provides an improved human-machine interface. All TG calibration operations can be carried out on the touch screen.

3. The furnace heating system utilizes custom-designed dual-coil nickel-chromium wire winding. This design not only reduces interference but also endows the furnace with higher resistance to high temperatures.

4. A USB communication interface is incorporated, which features high versatility and ensures reliable and uninterrupted communication. Additionally, it supports the auto-recovery connection function.

5. It can automatically switch between two gas flow channels, characterized by rapid switching speed and short stabilization time.

6. Digital flow meters are employed to achieve more precise control of gas flow.

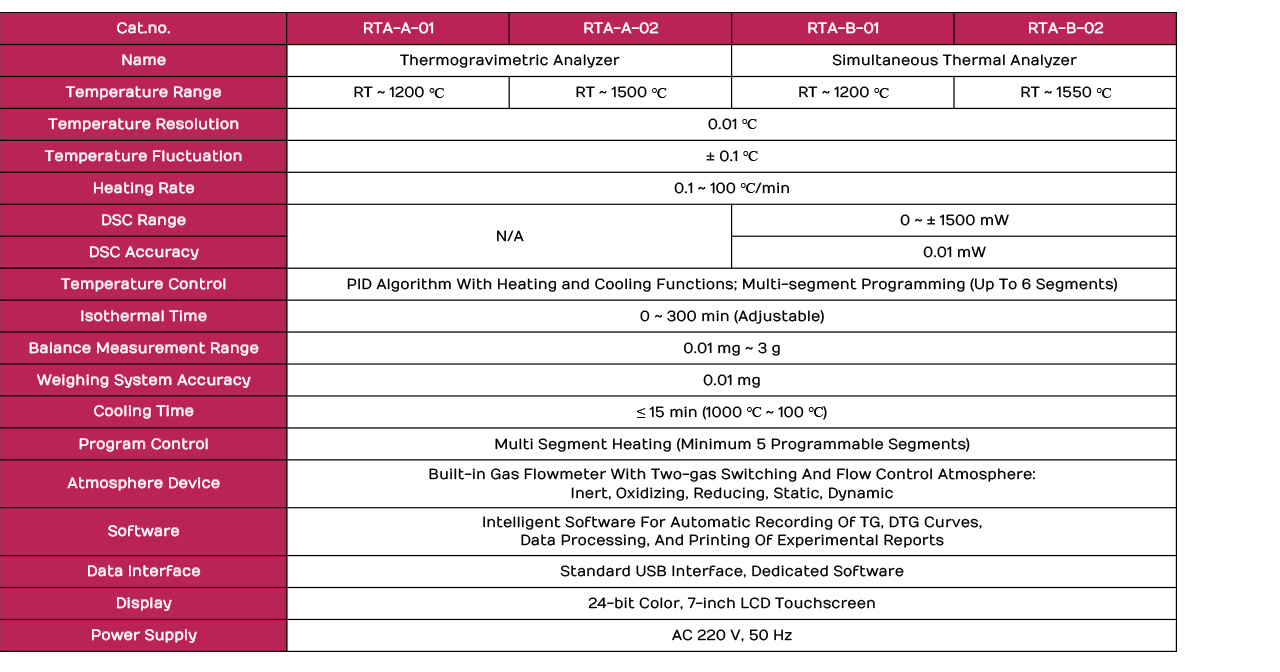

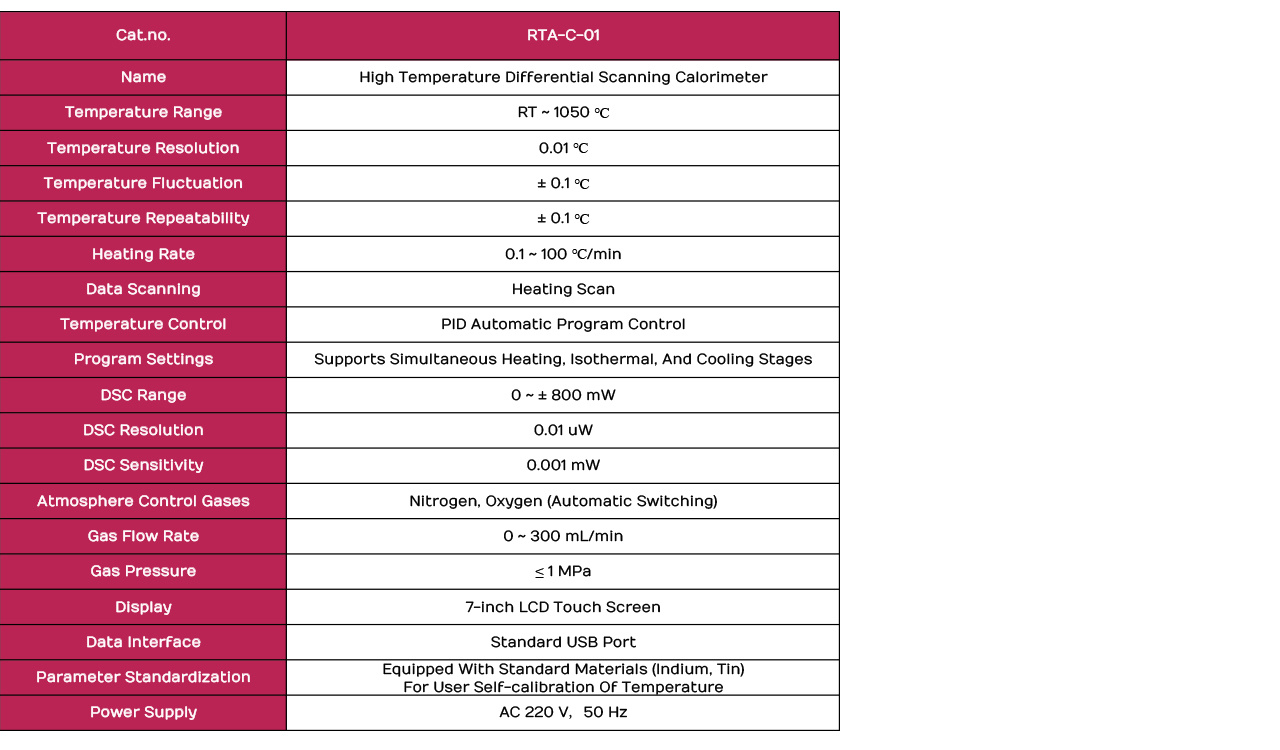

Technical data

Precautions

1. Temperature and humidity: Ensure the test environment temperature is stable and avoid significant fluctuations. Generally, the room temperature fluctuation should not exceed ±0.5℃.

2. No interference: During testing, ensure there is no obvious air flow, noise or vibration in the test environment.

3. Sample representativeness: Ensure the samples are representative and can reflect the true properties of the material.

4. Sample size and shape: Prepare the samples into appropriate shapes and sizes according to the test requirements, avoiding being too large or too small which may affect the test results.

5. Preheating after startup: After startup, preheat for 30 minutes and wait for the instrument to stabilize before conducting the test.

6. Temperature control: Set the correct temperature range and heating rate to ensure the stability and uniformity of the temperature control system.

7. Stress loading: The dynamic thermomechanical analyzer requires selecting appropriate test frequency to ensure the stability and uniformity of the stress loading system.

8. Data collection and processing: Use the software tools provided by the manufacturer for data collection and analysis, and ensure understanding of how to apply various mathematical functions and evaluation procedures.

9. Safe operation: Follow all safety guidelines, including properly grounding the instrument, using the appropriate power supply, and using protective equipment when necessary.

10. Instrument cleaning: Keep the instrument clean and regularly clean the surface and key components of the instrument to avoid dust and impurities affecting the test results.

11. Regular calibration: Regularly calibrate the instrument's accuracy to ensure the accuracy and reliability of the test results.

12. Dust and moisture prevention: When the equipment is idle, take good measures to prevent dust and moisture.

13. User permission management: If multiple users use the same equipment, use the user permission management software option to set up unique accounts and specific roles for each user to protect data and prevent misoperation.

14. Abnormal situation handling: During the test process, closely monitor the operation status of the instrument and changes in test data to promptly identify problems and take corresponding measures.

keyword:

Thermal Analyzer

Thermogravimetric Analyzer(TGA)

Simultaneous Thermal Analyzer(STA)

Differential Scanning Calorimeter(DSC) Analyzer

Thermogravimetric Analyzer

Simultaneous Thermal Analyzer

High-Temperature Differential Scanning Calorimeter

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Thermal Analyzer

- Subtitle: Thermal Analyzer

- Model: RTA-A,RTA-B,RTA-C

- 全部型号: RTA-A-01,RTA-A-02,RTA-B-01,RTA-B-02,RTA-C-01Thermal Analyzer,Thermogravimetric Analyzer(TGA),Simultaneous Thermal Analyzer(STA),Differential Scanning Calorimeter(DSC) Analyzer,Thermogravimetric Analyzer,Simultaneous Thermal Analyzer,High-Temperature Differential Scanning Calorimeter

Thermal analyzer is an apparatus employed to investigate the thermal and mechanical properties of materials.

Thermal analyzer is an apparatus employed to investigate the thermal and mechanical properties of materials. It is capable of analyzing parameters such as the phase transition temperature and thermal stability of materials. This instrument finds extensive applications in the fields of materials science, chemistry, physics, and engineering.

-

1. An ARM processor is adopted, enabling faster sampling and processing speeds.

2. A 7-inch full-color 24-bit touch screen provides an improved human-machine interface. All TG calibration operations can be carried out on the touch screen.

3. The furnace heating system utilizes custom-designed dual-coil nickel-chromium wire winding. This design not only reduces interference but also endows the furnace with higher resistance to high temperatures.

4. A USB communication interface is incorporated, which features high versatility and ensures reliable and uninterrupted communication. Additionally, it supports the auto-recovery connection function.

5. It can automatically switch between two gas flow channels, characterized by rapid switching speed and short stabilization time.

6. Digital flow meters are employed to achieve more precise control of gas flow. -

Precautions

1. Temperature and humidity: Ensure the test environment temperature is stable and avoid significant fluctuations. Generally, the room temperature fluctuation should not exceed ±0.5℃.

2. No interference: During testing, ensure there is no obvious air flow, noise or vibration in the test environment.

3. Sample representativeness: Ensure the samples are representative and can reflect the true properties of the material.

4. Sample size and shape: Prepare the samples into appropriate shapes and sizes according to the test requirements, avoiding being too large or too small which may affect the test results.

5. Preheating after startup: After startup, preheat for 30 minutes and wait for the instrument to stabilize before conducting the test.

6. Temperature control: Set the correct temperature range and heating rate to ensure the stability and uniformity of the temperature control system.

7. Stress loading: The dynamic thermomechanical analyzer requires selecting appropriate test frequency to ensure the stability and uniformity of the stress loading system.

8. Data collection and processing: Use the software tools provided by the manufacturer for data collection and analysis, and ensure understanding of how to apply various mathematical functions and evaluation procedures.

9. Safe operation: Follow all safety guidelines, including properly grounding the instrument, using the appropriate power supply, and using protective equipment when necessary.

10. Instrument cleaning: Keep the instrument clean and regularly clean the surface and key components of the instrument to avoid dust and impurities affecting the test results.

11. Regular calibration: Regularly calibrate the instrument's accuracy to ensure the accuracy and reliability of the test results.

12. Dust and moisture prevention: When the equipment is idle, take good measures to prevent dust and moisture.

13. User permission management: If multiple users use the same equipment, use the user permission management software option to set up unique accounts and specific roles for each user to protect data and prevent misoperation.

14. Abnormal situation handling: During the test process, closely monitor the operation status of the instrument and changes in test data to promptly identify problems and take corresponding measures.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation