Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Friability Tester

Friability Tester

RBRT-A

Brand:

RUISCI

-

Click to select

- RBRT-A-04,Fixed Speed/Adjustable Time And Count

- RBRT-A-02,Fixed Speed/Rotation Count

- RBRT-A-03,Fixed Speed/Adjustable Rotation Count

- RBRT-A-05,Fixed Speed/Adjustable Rotation Count,1~99999 rotations

- RBRT-A-01,Adjustable Speed/Rotation Count

Inventory

840

隐藏域元素占位

Overview

The friability tester is an apparatus employed to evaluate the resistance of tablets to fragmentation under physical impact. By mimicking the frictional and collision forces that tablets are likely to experience during the production and transportation processes, this instrument utilizes a rotating drum to make the tablets roll and collide. Subsequently, the friability is calculated by means of weighing and examining the degree of damage.

Features

1. Single-channel dual-drum, synchronous operation: It adopts a single-Channel dual-drum design, allowing both drums to operate simultaneously, significantly enhancing the detection efficiency.

2. Precise control, intelligent and convenient: The instrument automatically and precisely controls the rotation speed and number of rotations of the drums, ensuring the stability and repeatability of the experimental parameters.

3. Transparent material, clear observation: The drums are made of high-quality acrylic glass, which is colorless and transparent, facilitating clear observation of the sample status during the experiment.

4. Dual-screen real-time monitoring: Equipped with dual LCD screens, it separately displays the preset values and real-time values, allowing the operator to easily grasp the experimental parameters.

5. Automatic timed shutdown, worry-free and labor-saving: It has an automatic timed shutdown function, which can accurately stop the operation according to the preset time, eliminating the need for manual supervision.

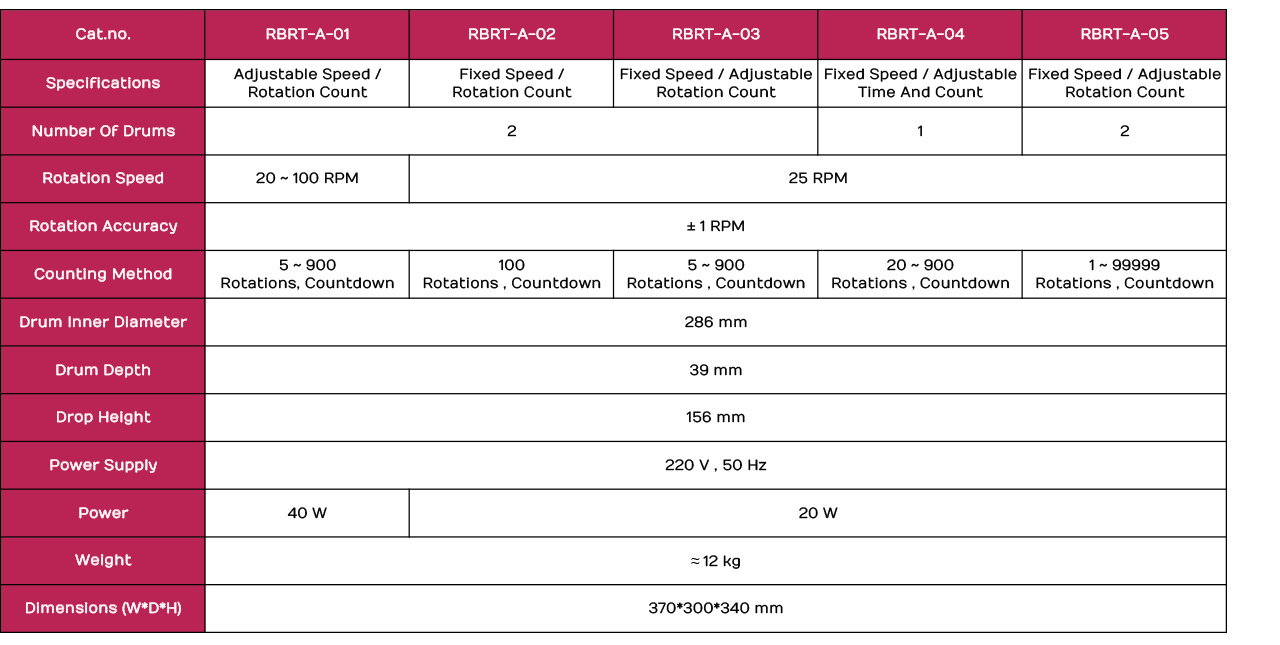

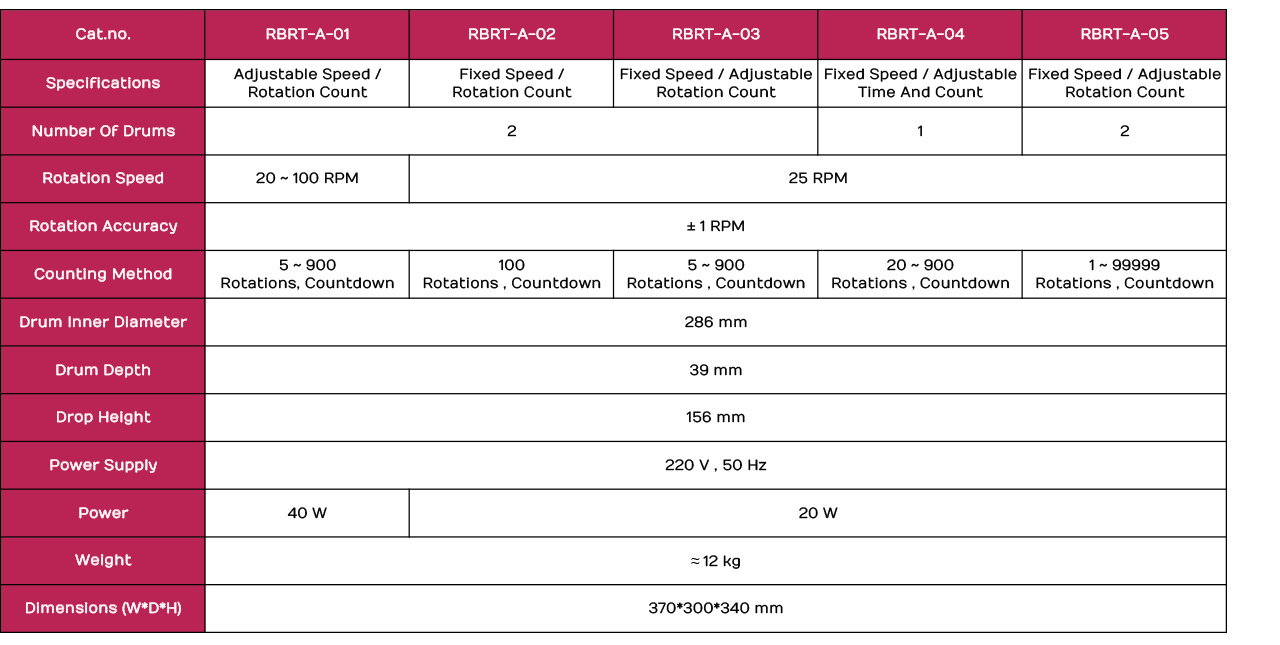

Technical data

Environmental requirements:

1. The ambient temperature should be controlled within 20 ± 10℃, and the relative humidity should not exceed 85%.

2. For moisture-absorbing samples, the ambient humidity should be kept below 40% to prevent moisture absorption from affecting the test results.

3. The sample surface should be clean, dry, and free of impurities.

Precautions:

1. Set the test parameters correctly, such as rotation speed, time, and count.

2. Avoid changing the working mode randomly during the experiment.

3. Prevent the equipment from being shaken or disturbed by humans during the test.

4. Carefully position and firmly secure samples to prevent slipping or ejection during the test.

5. Operators should wear protective gloves and goggles to avoid eye and hand injuries from sample splashes or fragments.

6. Do not allow fingers or other objects to approach the samples or clamps during the test.

7. Untrained or inexperienced personnel are not allowed to operate the instrument at will.

8. After the test, promptly clean the surface and interior of the instrument to remove any residual samples to avoid affecting the next test.

9. Use a clean soft cloth and appropriate cleaning agent for cleaning. Do not use hard objects to damage the instrument surface.

10. Regularly inspect the electrical components, mechanical parts, etc. of the instrument.

11. Regularly calibrate the instrument to ensure its accuracy and reliability.

12. Regularly maintain the instrument components, such as cleaning the distributor and grinder, and replacing worn parts.

13. After the test, turn off the power and unplug the instrument.

14. Store the instrument in a dry, clean, and non-corrosive gas environment.

keyword:

Friability Tester

Brittleness Tester

Granule Fragility Testing Equipment

Pharmaceutical Friability Tester Machine

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Friability Tester

- Subtitle: Friability Tester

- Model: RBRT-A

- 全部型号: RBRT-A-01,RBRT-A-02,RBRT-A-03,RBRT-A-04,RBRT-A-05,Friability Tester,Brittleness Tester,Granule Fragility Testing Equipment,Pharmaceutical Friability Tester Machine

The friability tester is an apparatus employed to evaluate the resistance of tablets to fragmentation under physical impact.

The friability tester is an apparatus employed to evaluate the resistance of tablets to fragmentation under physical impact. By mimicking the frictional and collision forces that tablets are likely to experience during the production and transportation processes, this instrument utilizes a rotating drum to make the tablets roll and collide. Subsequently, the friability is calculated by means of weighing and examining the degree of damage.

-

1. Single-channel dual-drum, synchronous operation: It adopts a single-Channel dual-drum design, allowing both drums to operate simultaneously, significantly enhancing the detection efficiency.

2. Precise control, intelligent and convenient: The instrument automatically and precisely controls the rotation speed and number of rotations of the drums, ensuring the stability and repeatability of the experimental parameters.

3. Transparent material, clear observation: The drums are made of high-quality acrylic glass, which is colorless and transparent, facilitating clear observation of the sample status during the experiment.

4. Dual-screen real-time monitoring: Equipped with dual LCD screens, it separately displays the preset values and real-time values, allowing the operator to easily grasp the experimental parameters.

5. Automatic timed shutdown, worry-free and labor-saving: It has an automatic timed shutdown function, which can accurately stop the operation according to the preset time, eliminating the need for manual supervision. -

Environmental requirements:

1. The ambient temperature should be controlled within 20 ± 10℃, and the relative humidity should not exceed 85%.

2. For moisture-absorbing samples, the ambient humidity should be kept below 40% to prevent moisture absorption from affecting the test results.

3. The sample surface should be clean, dry, and free of impurities.Precautions:

1. Set the test parameters correctly, such as rotation speed, time, and count.

2. Avoid changing the working mode randomly during the experiment.

3. Prevent the equipment from being shaken or disturbed by humans during the test.

4. Carefully position and firmly secure samples to prevent slipping or ejection during the test.

5. Operators should wear protective gloves and goggles to avoid eye and hand injuries from sample splashes or fragments.

6. Do not allow fingers or other objects to approach the samples or clamps during the test.

7. Untrained or inexperienced personnel are not allowed to operate the instrument at will.

8. After the test, promptly clean the surface and interior of the instrument to remove any residual samples to avoid affecting the next test.

9. Use a clean soft cloth and appropriate cleaning agent for cleaning. Do not use hard objects to damage the instrument surface.

10. Regularly inspect the electrical components, mechanical parts, etc. of the instrument.

11. Regularly calibrate the instrument to ensure its accuracy and reliability.

12. Regularly maintain the instrument components, such as cleaning the distributor and grinder, and replacing worn parts.

13. After the test, turn off the power and unplug the instrument.

14. Store the instrument in a dry, clean, and non-corrosive gas environment.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation