Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Vacuum Sterilizer

Vacuum Sterilizer

RVT-A,RVT-AC-A

Brand:

RUISCI

-

Click to select

- RVT-A-03,250L

- RVT-A-04,360L

- RVT-A-05,450L

- RVT-A-07,650L

- RVT-A-08,800L

- RVT-A-10,1000L

- RVT-A-12,1200L

- RVT-A-15,1500L

- RVT-A-20,2000L

- RVT-A-25,2500L

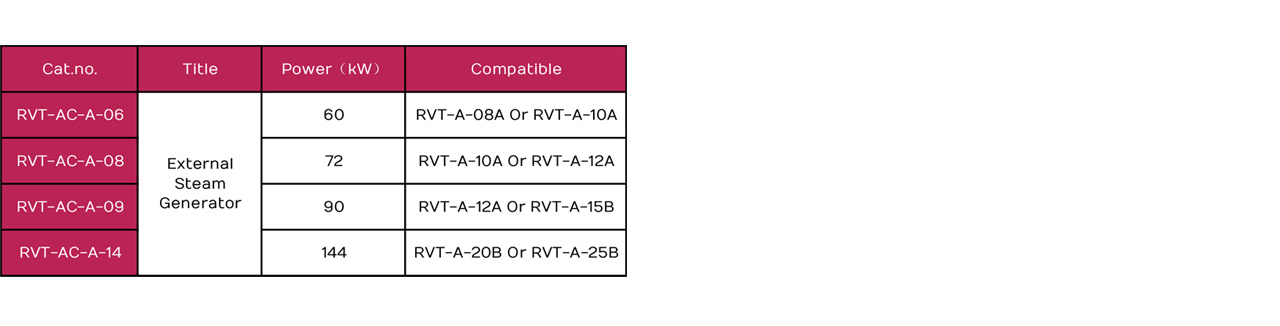

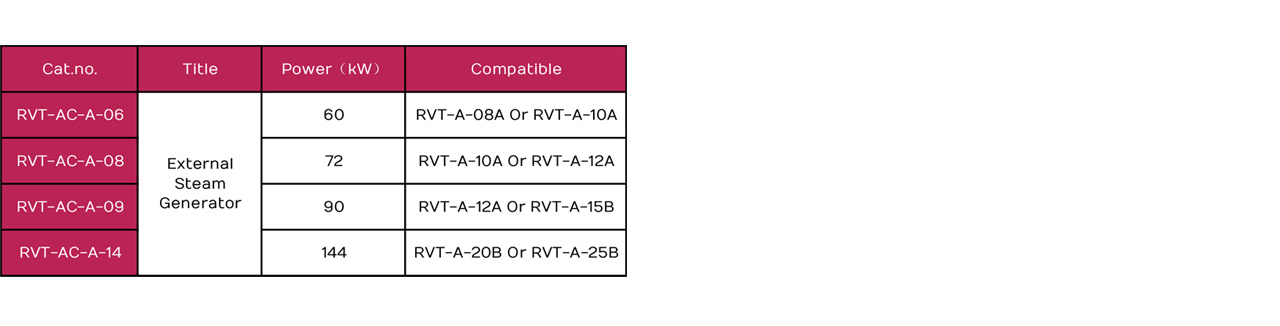

- RVT-AC-A-06,External Steam Generator,60kW

- RVT-AC-A-08,External Steam Generator,72kW

- RVT-AC-A-09,External Steam Generator,90kW

- RVT-AC-A-14,External Steam Generator,144kW

Inventory

2464

隐藏域元素占位

Overview

The pulsating vacuum steam sterilizer is a highly efficient sterilization device. It uses the alternating action of vacuum pumping and high-temperature steam to thoroughly remove the air in the sterilization chamber, allowing the steam to fully contact the items and achieve efficient sterilization. The sterilization temperature is usually 132℃ to 134℃, with a short sterilization time. It is suitable for use in hospitals, laboratories and other places, and can be used for the sterilization of medical devices, cloth items and other high-temperature resistant and moisture-resistant items.

Features

1. High-efficiency sterilization: Vacuum pumping combined with high-temperature steam ensures thorough sterilization.

2. Easy operation: Equipped with an intelligent control system, it is simple to operate and highly automated.

3. Safe and reliable: With overheat and overpressure protection, it ensures safe use.

4. Wide application: Suitable for various high-temperature and moisture-resistant items, it can be used in hospitals, laboratories and other places.

5. Energy-saving and durable: Energy-saving design, long service life and easy maintenance.

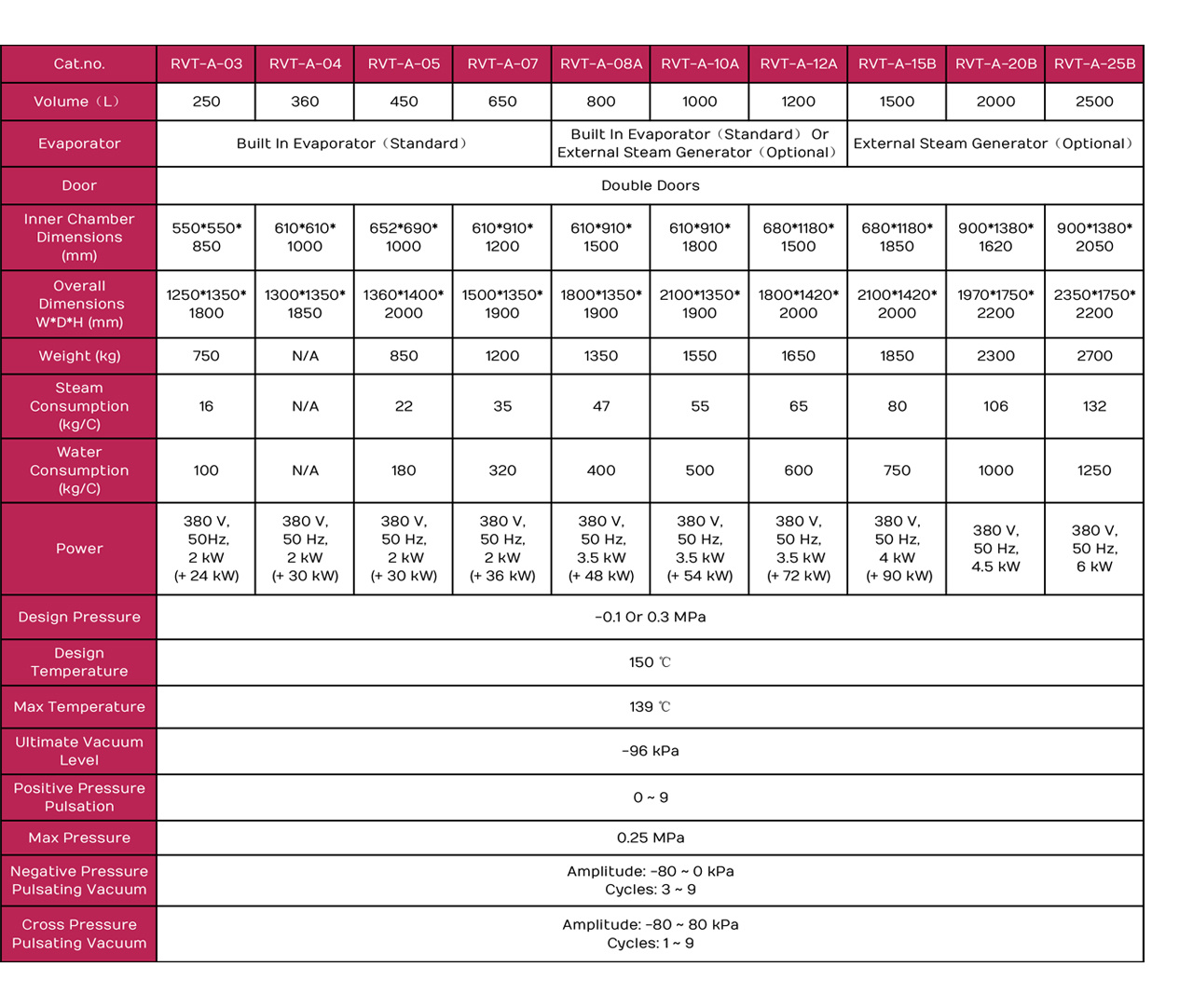

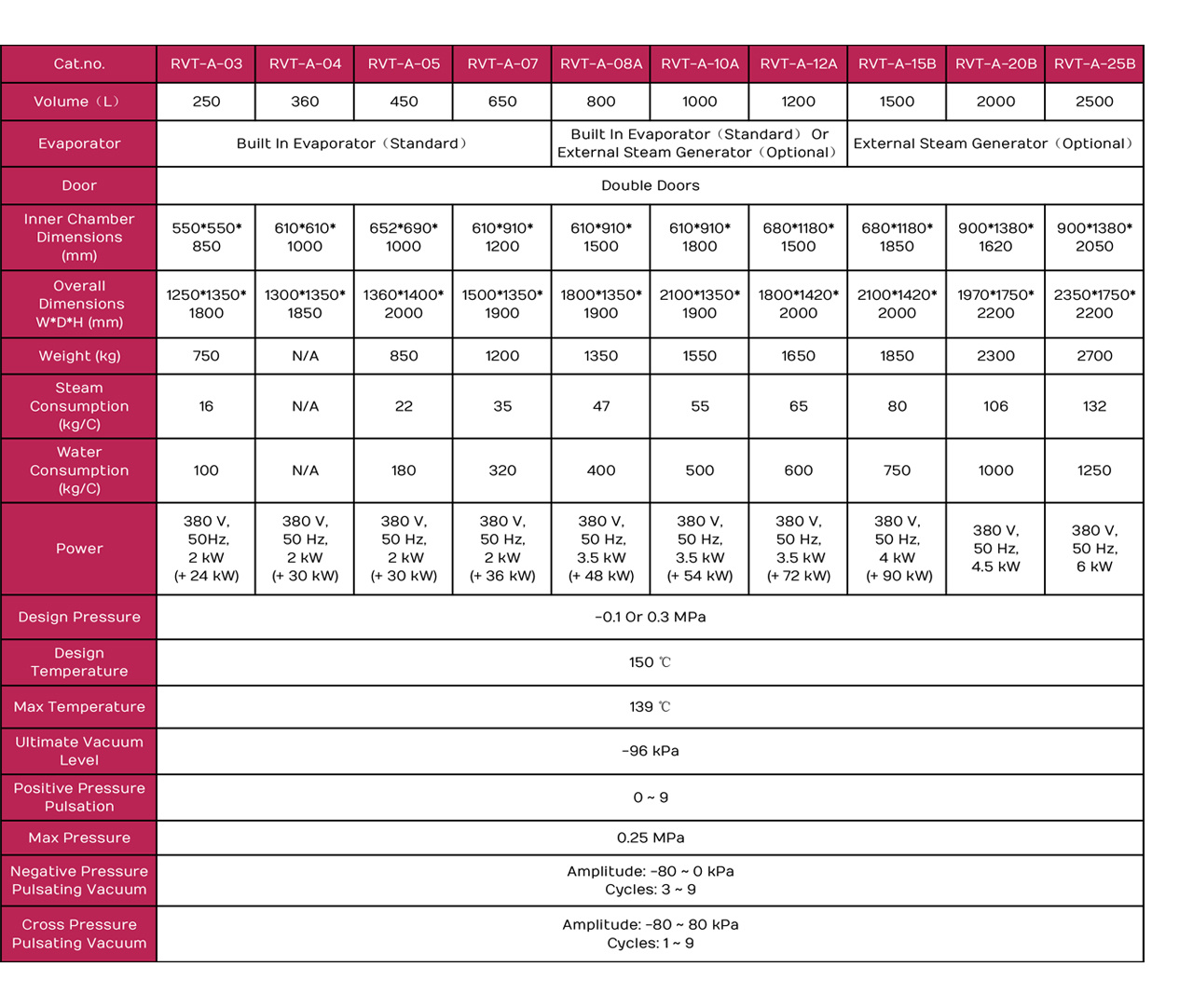

Technical data

Operation Precautions:

Before operation:

1. Check if the equipment components are functioning properly and ensure the sterilization chamber is clean.

2. Ensure that the items to be sterilized are clean, dry and loaded properly.

During operation:

1. Follow the procedures, conduct B-D test before operation and pay attention to the equipment operation status during the process.

2. Operators must remain near the equipment during operation. Only open the door after sterilization is complete and the pressure has returned to zero.

After operation:

1. Clean the equipment inside and out, and regularly clean the components such as the drainage valve and filter.

2. Regularly maintain the equipment, and monitor and record the sterilization effect for archiving.

keyword:

Vacuum Sterilizer

Pulsed Vacuum Steam Sterilizer

Previous:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Vacuum Sterilizer

- Subtitle: Vacuum Sterilizer

- Model: RVT-A,RVT-AC-A

- 全部型号: RVT-A-03,RVT-A-04,RVT-A-05,RVT-A-07,RVT-A-08,RVT-A-10,RVT-A-12,RVT-A-15,RVT-A-20,RVT-A-25,RVT-AC-A-06,RVT-AC-A-08,RVT-AC-A-09,RVT-AC-A-14,Vacuum Sterilizer,Pulsed Vacuum Steam Sterilizer

The pulsating vacuum steam sterilizer is a highly efficient sterilization device.

The pulsating vacuum steam sterilizer is a highly efficient sterilization device. It uses the alternating action of vacuum pumping and high-temperature steam to thoroughly remove the air in the sterilization chamber, allowing the steam to fully contact the items and achieve efficient sterilization. The sterilization temperature is usually 132℃ to 134℃, with a short sterilization time. It is suitable for use in hospitals, laboratories and other places, and can be used for the sterilization of medical devices, cloth items and other high-temperature resistant and moisture-resistant items.

-

1. High-efficiency sterilization: Vacuum pumping combined with high-temperature steam ensures thorough sterilization.

2. Easy operation: Equipped with an intelligent control system, it is simple to operate and highly automated.

3. Safe and reliable: With overheat and overpressure protection, it ensures safe use.

4. Wide application: Suitable for various high-temperature and moisture-resistant items, it can be used in hospitals, laboratories and other places.

5. Energy-saving and durable: Energy-saving design, long service life and easy maintenance. -

Operation Precautions:

Before operation:

1. Check if the equipment components are functioning properly and ensure the sterilization chamber is clean.

2. Ensure that the items to be sterilized are clean, dry and loaded properly.

During operation:

1. Follow the procedures, conduct B-D test before operation and pay attention to the equipment operation status during the process.

2. Operators must remain near the equipment during operation. Only open the door after sterilization is complete and the pressure has returned to zero.

After operation:

1. Clean the equipment inside and out, and regularly clean the components such as the drainage valve and filter.

2. Regularly maintain the equipment, and monitor and record the sterilization effect for archiving.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation