Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Coil Turns Measuring Instrument

Coil Turns Measuring Instrument

RCTM-A

Brand:

RUISCI

-

Click to select

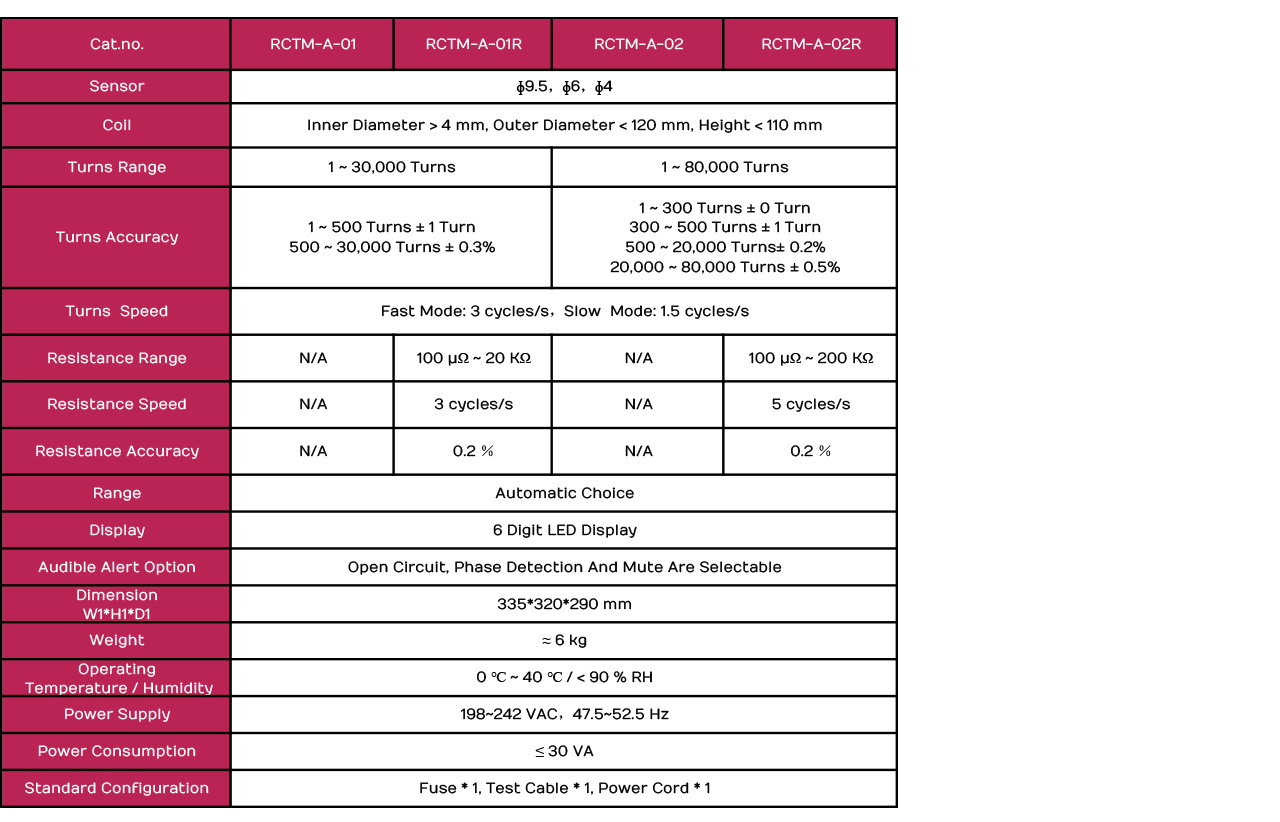

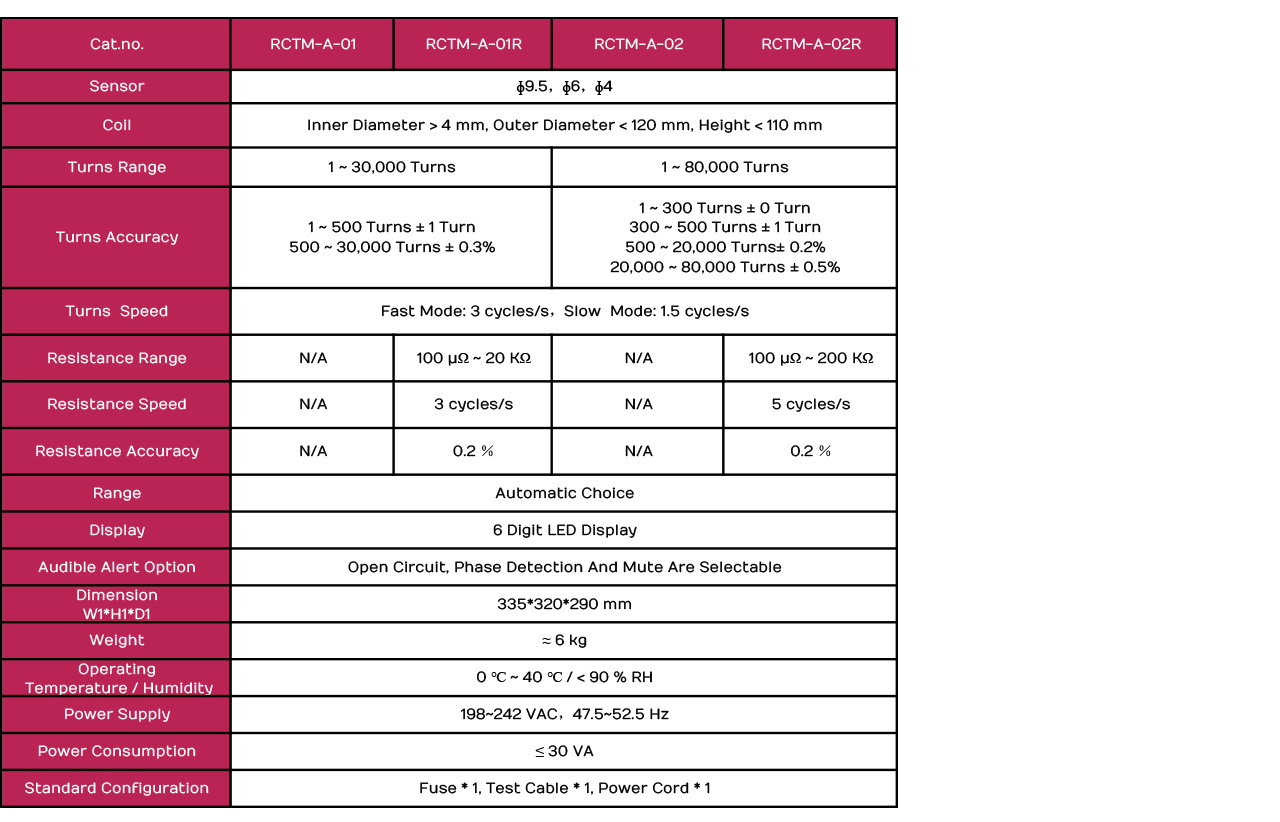

- RCTM-A-01,1 ~ 30,000 Turns,ɸ9.5,ɸ6,ɸ4

- RCTM-A-01R,1 ~ 30,000 Turns,3 cycles/s

- RCTM-A-02,1 ~ 80,000 Turns,ɸ9.5,ɸ6,ɸ4

- RCTM-A-02R,1 ~ 80,000 Turns,5 cycles/s

Inventory

1056

隐藏域元素占位

Overview

The Coil Turns Measuring Instrument is an electronic testing apparatus employed for measuring the number of coil turns and is extensively utilized in the domains of electronic component manufacturing, maintenance and inspection, among others.

Features

Features:

1. It boasts high measurement accuracy and a broad measurement range.

2. The operation is straightforward, with no requirement for complex calibration and range transformation.

3. The measurement speed is rapid, capable of enhancing the testing efficiency.

4. Certain models are equipped with the DC resistance measurement function. Capable of measuring both winding turns and coil DC resistance.

5. Non-contact measurement approach is employed, preventing damage to the measured components.

Technical data

Precautions:

1. To guarantee the measurement accuracy of the instrument, when the inner diameter of the tested coil is larger than 30mm, please select the ɸ9.5 sensor.

2. Large electromagnetic interference sources should be avoided around the tester; otherwise, the measurement accuracy might be affected.

3. The tester should be grounded reliably to prevent high-voltage electric shock and ensure the accuracy of the test results.

4. Make sure that the power supply voltage and frequency comply with the equipment requirements.

5. The tested coil should be sleeved onto the test rod of the sensor. Ensure that the lower end of the coil winding is closely attached to the test bench surface, and the test rod is at the center of the coil.

6. During the testing process, the other untested windings should not be short-circuited to the ground; otherwise, the measurement results might be influenced.

7. The test sensor should not be impacted. The rotation angle should not exceed 45°, and it should not be disassembled randomly to avoid affecting the accuracy.

8. In the testing state and when the stop light is not on, do not touch the test terminal and the tested coil to beware of high-voltage electric shock.

9. When replacing the test winding, it must be carried out when the stop light is on. The test can be initiated only after the replacement is completed.

10. The instrument should be placed and used in an environment with good ventilation, no high humidity, and little dust.

11. After the instrument is powered off, it can be wiped with a soft fabric, but corrosive solvents should be avoided.

12. The instrument should be stored under the original packaging conditions, with an ambient temperature of 0 - 40°C, a relative humidity not exceeding 85%, and no corrosive substances in the air.

13. To ensure the measurement accuracy, the instrument should be calibrated periodically.

14. Regularly inspect whether the connection lines of the sensors are loose or damaged to ensure the normal operation of the sensors.

keyword:

Coil Turn Tester,Coil Turns Counter

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Coil Turns Measuring Instrument

- Subtitle: Coil Turns Measuring Instrument

- Model: RCTM-A

- 全部型号: Coil Turn Tester,Coil Turns Counter,RCTM-A-01,RCTM-A-01R,RCTM-A-02,RCTM-A-02R

The Coil Turns Measuring Instrument is an electronic testing apparatus employed for measuring the number of coil turns and is extensively utilized in the domains of electronic component manufacturing, maintenance and inspection, among others.

The Coil Turns Measuring Instrument is an electronic testing apparatus employed for measuring the number of coil turns and is extensively utilized in the domains of electronic component manufacturing, maintenance and inspection, among others.

-

Features:

1. It boasts high measurement accuracy and a broad measurement range.

2. The operation is straightforward, with no requirement for complex calibration and range transformation.

3. The measurement speed is rapid, capable of enhancing the testing efficiency.

4. Certain models are equipped with the DC resistance measurement function. Capable of measuring both winding turns and coil DC resistance.

5. Non-contact measurement approach is employed, preventing damage to the measured components. -

Precautions:

1. To guarantee the measurement accuracy of the instrument, when the inner diameter of the tested coil is larger than 30mm, please select the ɸ9.5 sensor.

2. Large electromagnetic interference sources should be avoided around the tester; otherwise, the measurement accuracy might be affected.

3. The tester should be grounded reliably to prevent high-voltage electric shock and ensure the accuracy of the test results.

4. Make sure that the power supply voltage and frequency comply with the equipment requirements.

5. The tested coil should be sleeved onto the test rod of the sensor. Ensure that the lower end of the coil winding is closely attached to the test bench surface, and the test rod is at the center of the coil.

6. During the testing process, the other untested windings should not be short-circuited to the ground; otherwise, the measurement results might be influenced.

7. The test sensor should not be impacted. The rotation angle should not exceed 45°, and it should not be disassembled randomly to avoid affecting the accuracy.

8. In the testing state and when the stop light is not on, do not touch the test terminal and the tested coil to beware of high-voltage electric shock.

9. When replacing the test winding, it must be carried out when the stop light is on. The test can be initiated only after the replacement is completed.

10. The instrument should be placed and used in an environment with good ventilation, no high humidity, and little dust.

11. After the instrument is powered off, it can be wiped with a soft fabric, but corrosive solvents should be avoided.

12. The instrument should be stored under the original packaging conditions, with an ambient temperature of 0 - 40°C, a relative humidity not exceeding 85%, and no corrosive substances in the air.

13. To ensure the measurement accuracy, the instrument should be calibrated periodically.

14. Regularly inspect whether the connection lines of the sensors are loose or damaged to ensure the normal operation of the sensors.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation