Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

Activated Carbon Exhaust Treatment Device

Activated Carbon Exhaust Treatment Device

RAC-A,RAC-B

Brand:

RUISCI

-

Click to select

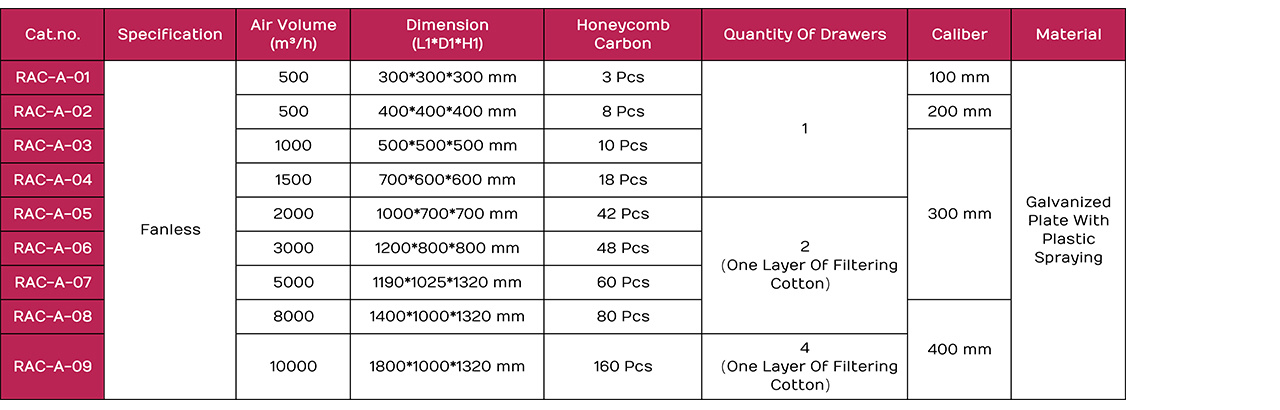

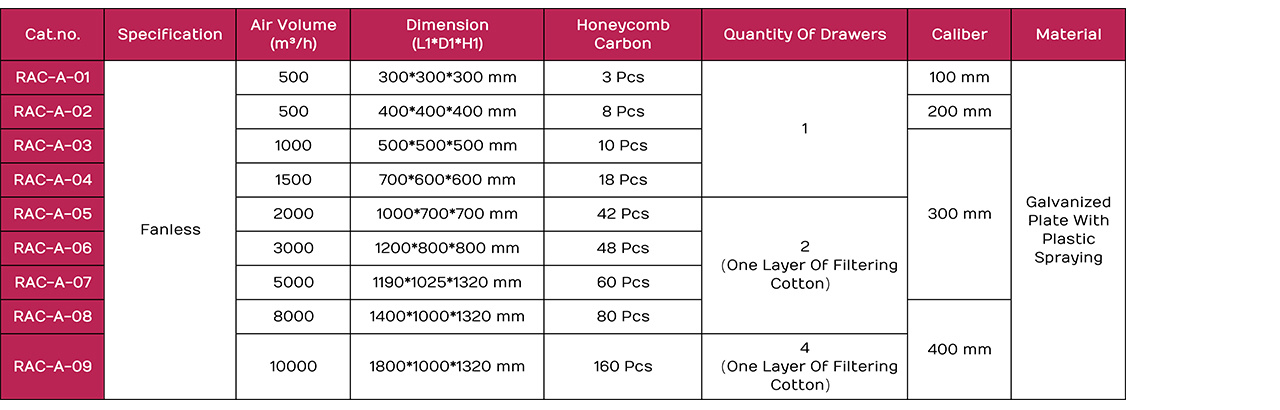

- RAC-A-01,Fanless

- RAC-A-02,Fanless

- RAC-A-03,Fanless

- RAC-A-04,Fanless

- RAC-A-05,Fanless

- RAC-A-06,Fanless

- RAC-A-07,Fanless

- RAC-A-08,Fanless

- RAC-A-09,Fanless

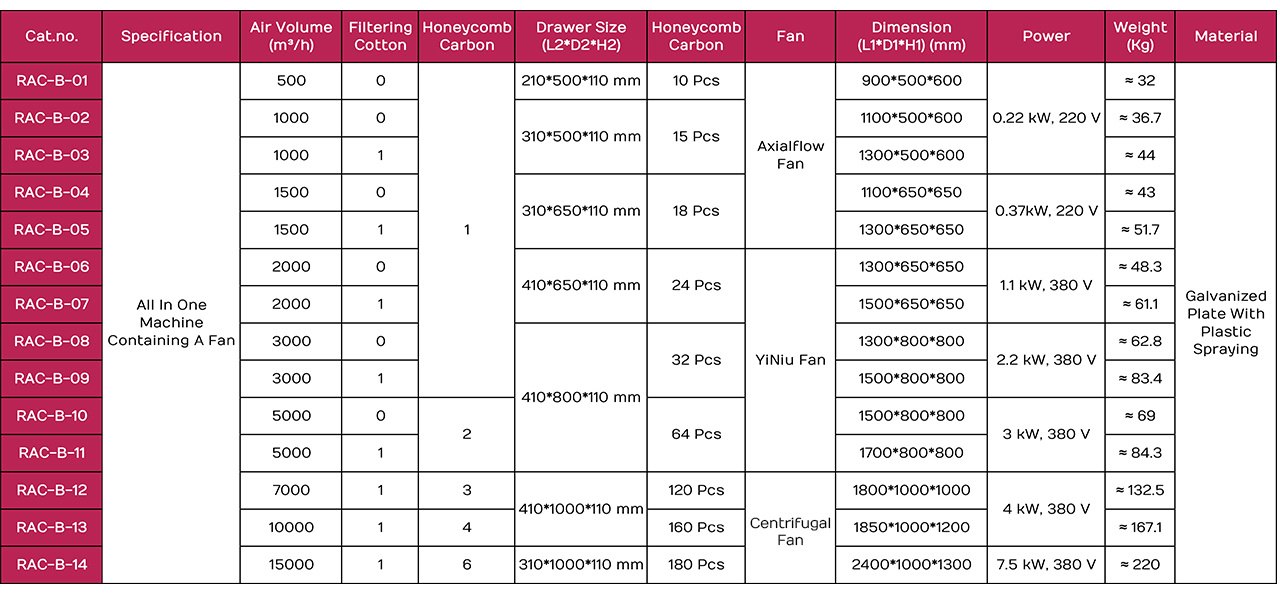

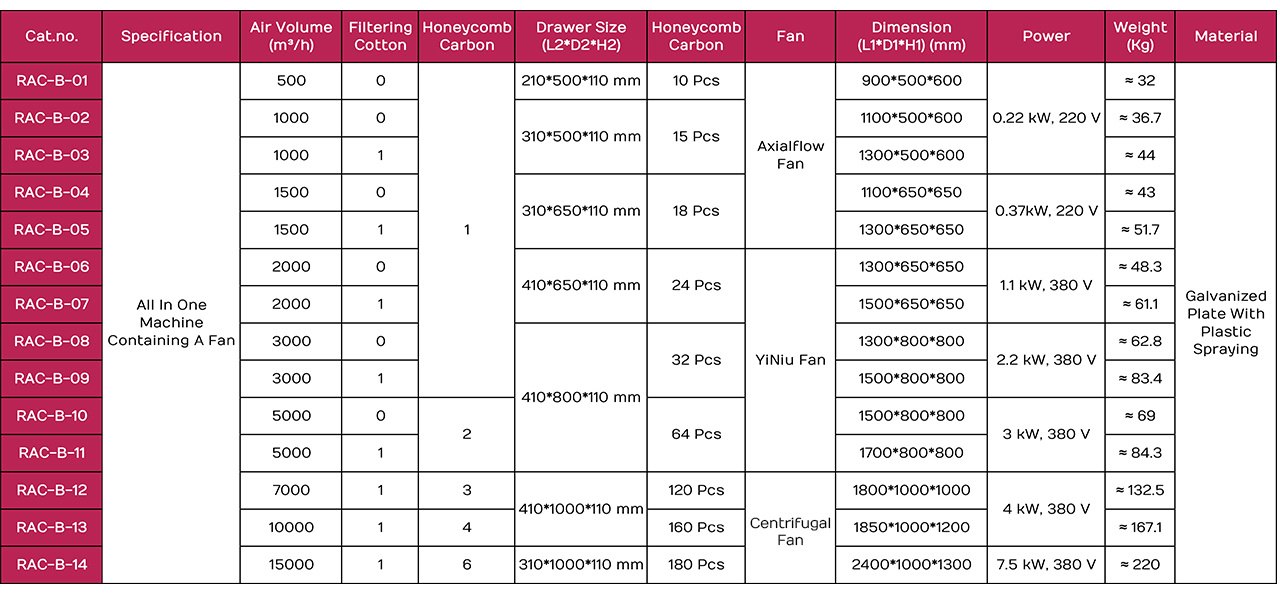

- RAC-B-01

- RAC-B-02

- RAC-B-03

- RAC-B-04

- RAC-B-05

- RAC-B-06

- RAC-B-07

- RAC-B-08

- RAC-B-09

- RAC-B-10

- RAC-B-11

- RAC-B-12

- RAC-B-13

- RAC-B-14

Inventory

3864

隐藏域元素占位

Overview

The activated carbon exhaust treatment device is a device employed for purifying laboratories. It exploits the high adsorption capacity of activated carbon to effectively eliminate organic compounds, odors, and harmful gases from the exhaust gas. This apparatus features a compact structure, straightforward operation, and low maintenance costs. It is applicable for treating waste gas with small air volumes and low concentrations, and can conspicuously enhance air quality and safeguard the health of laboratory personnel. It constitutes an essential equipment in laboratories.

Features

1. Highly Efficient Adsorption: Specifically, high-iodine-value honeycomb activated carbon is adopted, featuring a high iodine value, excellent purification efficiency, and strong adsorption capability. It can effectively eliminate organic waste gases, odors, and harmful gases.

2. Extensive Applicability: It is capable of treating a variety of mixed waste gases and is applicable to laboratories in chemistry, biology, and other disciplines.

3. Compact Equipment: With a small volume and occupying a limited area, it is suitable for laboratory settings with constrained space.

4. Simple Operation: Automated control is implemented, enabling straightforward operation, convenient maintenance, and low running costs.

5. Safe and Dependable: The fully enclosed design prevents gas leakage and guarantees laboratory safety.

6. Internal Fan: A pure copper motor is utilized, and an integrated design is adopted with the fan built internally, offering a large air volume and stable operation.

7. Filter Cotton: It is equipped with primary filter cotton for the initial filtration of paint mist, water vapor, and large-particle pollutants, etc.

Technical data

Environment Conditions:

1. The optimum working temperature range is 20°C - 40°C.

2. The relative humidity should be controlled within 40% - 60%.

3. Ventilation: It should be installed in a well-ventilated location, far away from fire sources and heat sources.

Precautions:

1. The adsorption capacity of activated carbon is limited. With the increase of usage time, its adsorption performance will gradually decline. When the pressure drop of the equipment significantly increases or the pollutant concentration in the treated gas rises, the activated carbon should be replaced promptly.

2. The replacement cycle varies depending on the usage environment and the composition of the exhaust gas. Generally, it is recommended to check the adsorption effect of the activated carbon every 3 to 6 months.

3. If the temperature of the exhaust gas is overly high, a cooling device can be installed before the exhaust gas enters the adsorption box; if the humidity is high, a dehumidification device can be installed.

4. The designed air volume of the activated carbon exhaust gas treatment device is fixed. Select an appropriate air volume to avoid influencing the adsorption effect.

5. After activated carbon adsorbs certain organic solvents, it may spontaneously combust due to heat accumulation. Especially when treating high-concentration organic exhaust gas, special attention should be paid to the temperature changes of the equipment.

6. Regularly inspect the internal temperature of the equipment. Install temperature sensors and alarm devices when necessary.

7. Regularly check the sealing performance of the equipment to prevent exhaust gas leakage.

8. Clean the outer casing and internal components of the equipment, especially the fan and filter, to maintain good ventilation effect.

9. Inspect the electrical circuits to ensure the safe operation of the equipment.

10. Ensure that the inlet and outlet connections of the equipment are correct to prevent gas short-circuiting.

11. The adsorption capacity of activated carbon for different types of pollutants varies. For some strongly acidic or strongly alkaline gases, pretreatment or the use of specialized activated carbon may be necessary.

12. If the exhaust gas contains a large amount of particulate matter, a pre-filter should be installed before the activated carbon adsorption box to prevent the blockage of activated carbon.

13. When replacing activated carbon or conducting equipment maintenance, wear appropriate protective equipment such as gloves and masks.

keyword:

Activated Carbon Exhaust Treatment Device

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Activated Carbon Exhaust Treatment Device

- Subtitle: Activated Carbon Exhaust Treatment Device

- Model: RAC-A,RAC-B

- 全部型号: RAC-A-01,RAC-A-02,RAC-A-03,RAC-A-04,RAC-A-05,RAC-A-06,RAC-A-07,RAC-A-08,RAC-A-09, RAC-B-01,RAC-B-02,RAC-B-03,RAC-B-04,RAC-B-05,RAC-B-06,,RAC-B-07,RAC-B-08,RAC-B-09,RAC-B-10,RAC-B-11,RAC-B-12,RAC-B-13,RAC-B-14,Activated Carbon Exhaust Treatment Device

The activated carbon exhaust treatment device is a device employed for purifying laboratories.

The activated carbon exhaust treatment device is a device employed for purifying laboratories. It exploits the high adsorption capacity of activated carbon to effectively eliminate organic compounds, odors, and harmful gases from the exhaust gas. This apparatus features a compact structure, straightforward operation, and low maintenance costs. It is applicable for treating waste gas with small air volumes and low concentrations, and can conspicuously enhance air quality and safeguard the health of laboratory personnel. It constitutes an essential equipment in laboratories.

-

1. Highly Efficient Adsorption: Specifically, high-iodine-value honeycomb activated carbon is adopted, featuring a high iodine value, excellent purification efficiency, and strong adsorption capability. It can effectively eliminate organic waste gases, odors, and harmful gases.

2. Extensive Applicability: It is capable of treating a variety of mixed waste gases and is applicable to laboratories in chemistry, biology, and other disciplines.

3. Compact Equipment: With a small volume and occupying a limited area, it is suitable for laboratory settings with constrained space.

4. Simple Operation: Automated control is implemented, enabling straightforward operation, convenient maintenance, and low running costs.

5. Safe and Dependable: The fully enclosed design prevents gas leakage and guarantees laboratory safety.

6. Internal Fan: A pure copper motor is utilized, and an integrated design is adopted with the fan built internally, offering a large air volume and stable operation.

7. Filter Cotton: It is equipped with primary filter cotton for the initial filtration of paint mist, water vapor, and large-particle pollutants, etc. -

Environment Conditions:

1. The optimum working temperature range is 20°C - 40°C.

2. The relative humidity should be controlled within 40% - 60%.

3. Ventilation: It should be installed in a well-ventilated location, far away from fire sources and heat sources.Precautions:

1. The adsorption capacity of activated carbon is limited. With the increase of usage time, its adsorption performance will gradually decline. When the pressure drop of the equipment significantly increases or the pollutant concentration in the treated gas rises, the activated carbon should be replaced promptly.

2. The replacement cycle varies depending on the usage environment and the composition of the exhaust gas. Generally, it is recommended to check the adsorption effect of the activated carbon every 3 to 6 months.

3. If the temperature of the exhaust gas is overly high, a cooling device can be installed before the exhaust gas enters the adsorption box; if the humidity is high, a dehumidification device can be installed.

4. The designed air volume of the activated carbon exhaust gas treatment device is fixed. Select an appropriate air volume to avoid influencing the adsorption effect.

5. After activated carbon adsorbs certain organic solvents, it may spontaneously combust due to heat accumulation. Especially when treating high-concentration organic exhaust gas, special attention should be paid to the temperature changes of the equipment.

6. Regularly inspect the internal temperature of the equipment. Install temperature sensors and alarm devices when necessary.

7. Regularly check the sealing performance of the equipment to prevent exhaust gas leakage.

8. Clean the outer casing and internal components of the equipment, especially the fan and filter, to maintain good ventilation effect.

9. Inspect the electrical circuits to ensure the safe operation of the equipment.

10. Ensure that the inlet and outlet connections of the equipment are correct to prevent gas short-circuiting.

11. The adsorption capacity of activated carbon for different types of pollutants varies. For some strongly acidic or strongly alkaline gases, pretreatment or the use of specialized activated carbon may be necessary.

12. If the exhaust gas contains a large amount of particulate matter, a pre-filter should be installed before the activated carbon adsorption box to prevent the blockage of activated carbon.

13. When replacing activated carbon or conducting equipment maintenance, wear appropriate protective equipment such as gloves and masks.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation