Quality Assured

Just Buy It

- Comparison

- 在线预约

- 预约申请

- 样品申请

- 在线询价

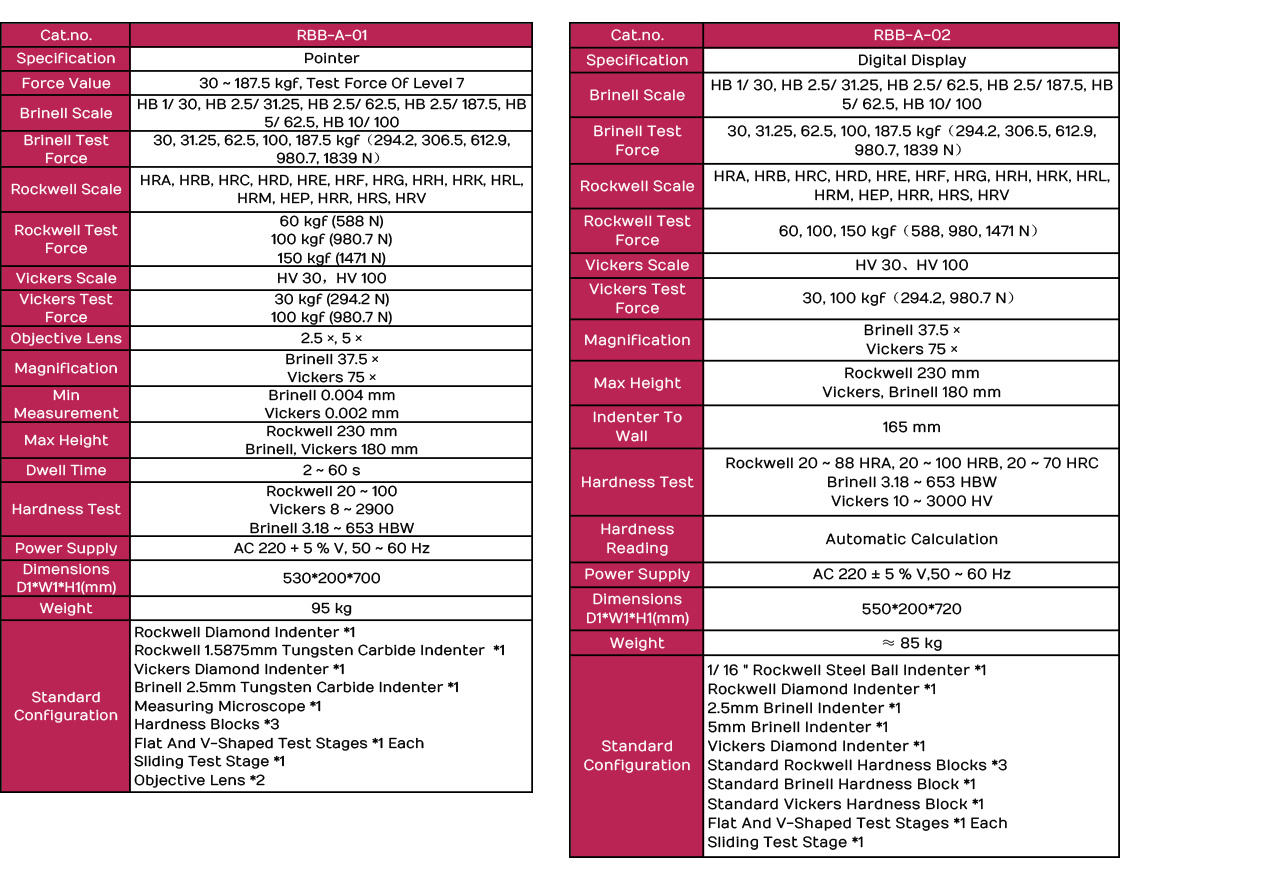

Brinell Rockwell Vickers Hardness Tester

Brinell Rockwell Vickers Hardness Tester

RBB-A

Brand:

RUISCI

-

Click to select

- RBB-A-01,Pointer

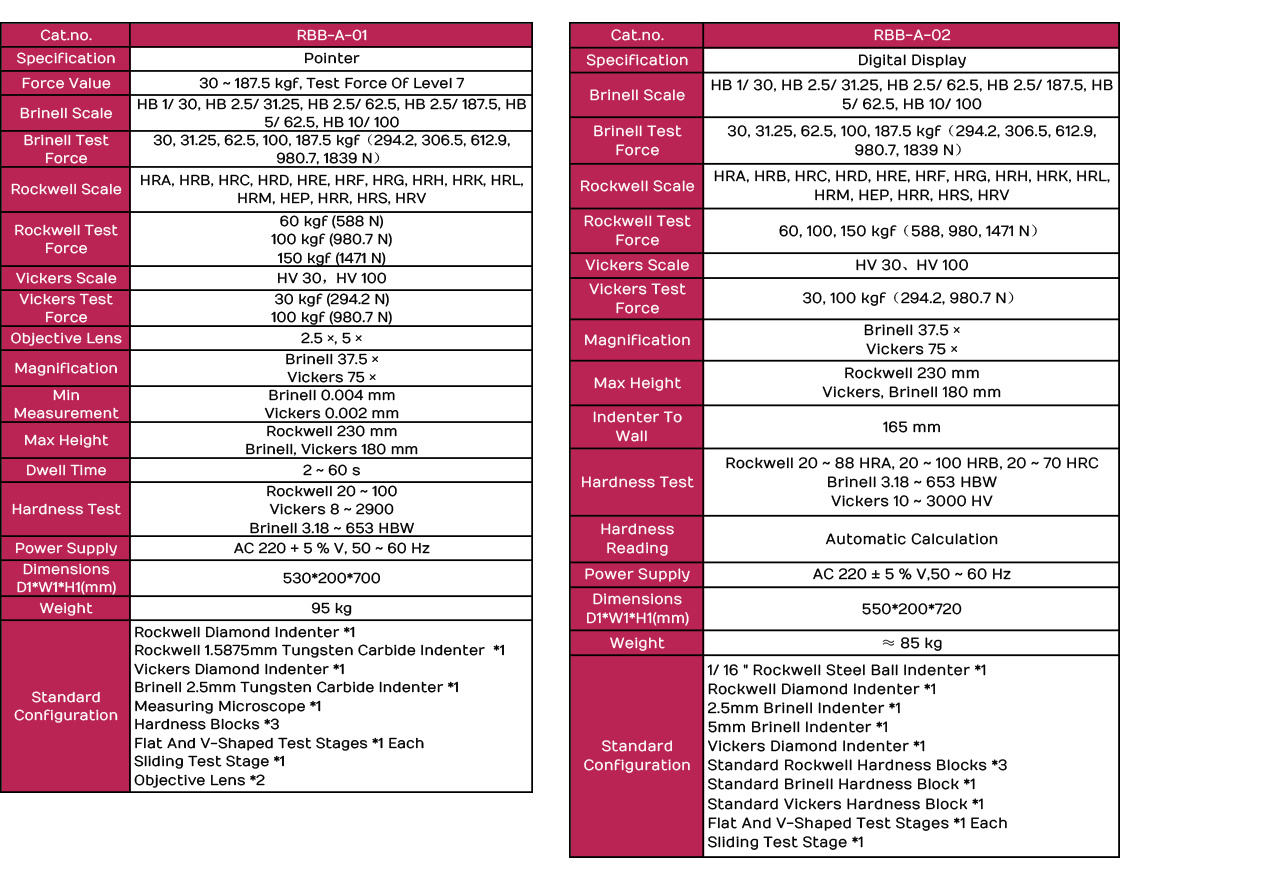

- RBB-A-02,Digital Display

Inventory

358

隐藏域元素占位

Overview

Brinell Rockwell Vickers Hardness Tester is a multi-functional and versatile hardness tester that features three testing methods - Brinell, Rockwell, and Vickers - and seven levels of testing force. It can meet the diverse hardness testing requirements of users.

Features

RBB-A-01:

1. The optical system designed by senior optical engineers not only provides clear images but also can be used as a simple microscope. It features adjustable brightness, comfortable vision, and is not prone to causing fatigue even after long-term operation.

2. It is equipped with three testing methods: Brinell, Rockwell, and Vickers, and seven levels of test force, which can meet various hardness testing requirements.

3. The casting shell is formed in one piece, ensuring stable structure without deformation. It is coated with pure white automotive paint, which is of high grade and has strong scratch resistance. It remains as bright as new even after years of use.

RBB-A-02:

1. The 7-inch LCD touch screen can directly display hardness values, hardness conversions, testing methods, test force, brightness, holding time, measurement times, statistical data, and dwell time, making the testing process clear and intuitive.

2. The system comes with a built-in calibration function, allowing manual adjustment of input error calibration instruments.

3. When testing curved surfaces, it automatically corrects according to the standard curved surface radius.

4. The adjustable range of the optical system's brightness is 0-100.

5. It can store 100 sets of test data, allowing for viewing at any time, as well as deletion of current data or clearing all test data.

6. The test force unit can be manually selected and converted, with conversion units being: (kgf, N).

7. It is equipped with three testing methods: Brinell, Rockwell, and Vickers, and seven levels of test force, which can meet various hardness testing requirements.

Technical data

Precautions:

1. Installation requirements: Place on a stable and level workbench, and ensure good grounding.

2. Check the instrument: Confirm that all components are normal and electrical components are firmly fixed.

3. Sample requirements: The sample surface should be flat and smooth, with sufficient thickness. For cylindrical samples, a "V" shaped sample stage should be used.

4. Select parameters during the testing process: Choose appropriate load, dwell time, and other parameters based on the hardness range of the material.

5. Install the indenter: Ensure good contact between the indenter and the sample, and apply moderate pressure. Operating norms: Handle with care, and avoid rotating relevant handwheels when applying or releasing the test force.

6. Maintenance and cleaning after use: Regularly clean dust, cover with a dust cover after use, and apply anti-rust oil to the hardness blocks and indenters after use.

7. Regular calibration: Use standard hardness blocks for calibration to ensure measurement accuracy.

8. Safety precautions: Wear protective gear during operation to prevent electric shock, burns, and other accidents.

keyword:

Brinell Rockwell Vickers Hardness Tester

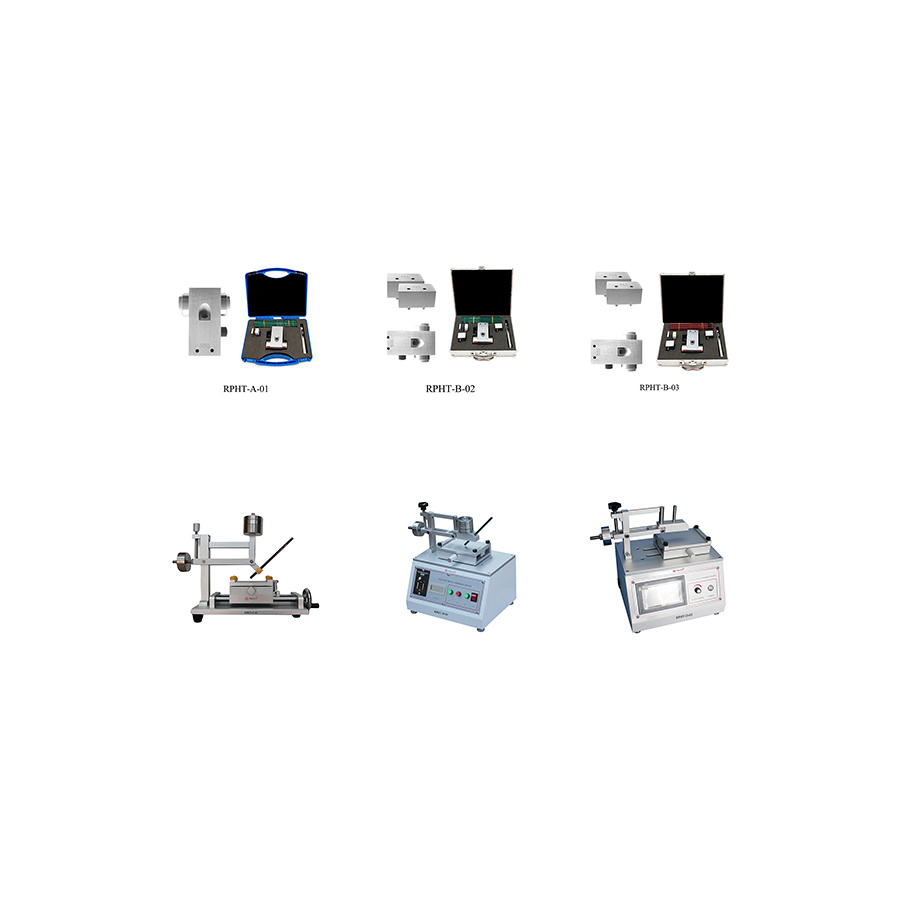

Portable Brinell Rockwell Vickers Hardness Tester

Digital Brinell Rockwell Vickers Hardness Tester

Previous:

Next:

- 产品描述

- 概要参数

- 技术参数

-

- Brand: RUISCI

- Commodity name: Brinell Rockwell Vickers Hardness Tester

- Subtitle: Brinell Rockwell Vickers Hardness Tester

- Model: RBB-A

- 全部型号: RBB-A-01,RBB-A-02,Brinell Rockwell Vickers Hardness Tester,Portable Brinell Rockwell Vickers Hardness Tester,Digital Brinell Rockwell Vickers Hardness Tester

Brinell Rockwell Vickers Hardness Tester is a multi-functional and versatile hardness tester.

Brinell Rockwell Vickers Hardness Tester is a multi-functional and versatile hardness tester that features three testing methods - Brinell, Rockwell, and Vickers - and seven levels of testing force. It can meet the diverse hardness testing requirements of users.

-

RBB-A-01:

1. The optical system designed by senior optical engineers not only provides clear images but also can be used as a simple microscope. It features adjustable brightness, comfortable vision, and is not prone to causing fatigue even after long-term operation.

2. It is equipped with three testing methods: Brinell, Rockwell, and Vickers, and seven levels of test force, which can meet various hardness testing requirements.

3. The casting shell is formed in one piece, ensuring stable structure without deformation. It is coated with pure white automotive paint, which is of high grade and has strong scratch resistance. It remains as bright as new even after years of use.RBB-A-02:

1. The 7-inch LCD touch screen can directly display hardness values, hardness conversions, testing methods, test force, brightness, holding time, measurement times, statistical data, and dwell time, making the testing process clear and intuitive.

2. The system comes with a built-in calibration function, allowing manual adjustment of input error calibration instruments.

3. When testing curved surfaces, it automatically corrects according to the standard curved surface radius.

4. The adjustable range of the optical system's brightness is 0-100.

5. It can store 100 sets of test data, allowing for viewing at any time, as well as deletion of current data or clearing all test data.

6. The test force unit can be manually selected and converted, with conversion units being: (kgf, N).

7. It is equipped with three testing methods: Brinell, Rockwell, and Vickers, and seven levels of test force, which can meet various hardness testing requirements. -

Precautions:

1. Installation requirements: Place on a stable and level workbench, and ensure good grounding.

2. Check the instrument: Confirm that all components are normal and electrical components are firmly fixed.

3. Sample requirements: The sample surface should be flat and smooth, with sufficient thickness. For cylindrical samples, a "V" shaped sample stage should be used.

4. Select parameters during the testing process: Choose appropriate load, dwell time, and other parameters based on the hardness range of the material.

5. Install the indenter: Ensure good contact between the indenter and the sample, and apply moderate pressure. Operating norms: Handle with care, and avoid rotating relevant handwheels when applying or releasing the test force.

6. Maintenance and cleaning after use: Regularly clean dust, cover with a dust cover after use, and apply anti-rust oil to the hardness blocks and indenters after use.

7. Regular calibration: Use standard hardness blocks for calibration to ensure measurement accuracy.

8. Safety precautions: Wear protective gear during operation to prevent electric shock, burns, and other accidents.

Q and A

Q

Distribution Modes:

A

Default Distribution Mode: EXW China Factory: After your payment is received, our customer service will contact you to confirm the pickup time and location once the goods are ready at the RUISCI China factory.

*Other options:

1.Carriage Paid To (CPT)

DO NOT PAY until you have contacted customer service to add shipping costs, as the default price is EXW China factory.

2.Delivered Duty Paid(DDP)

DO NOT PAY until you have ·contacted customer service to add Freight, insurance, taxes, customs clearance fees, and other miscellaneous expenses, as the default price is EXW China factory. Typically applies exclusively to small air cargo packages.

3. FOB China main port

DO NOT PAY until you have contacted customer service to add the inland charges and export declaration charges, as the default price is EXW China factory.

*** If you still need to consult other distribution modes or trade terms, please contact our customer service directly

Q

Payment methods:

A

1. On-line payment: Paypal

2. Off-line payment: Telegraphic Transfer (TT)

*All charges, except those incurred within our bank, are to be borne by the remitter. Insufficient payment will delay your shipment.

Download

There is currently no content to display

Related products

Online consultation